Loading ...

Loading ...

Loading ...

Check Detergent Siphoning Tube

Examinedetergent tube and dean if clogge& The tube

should fit tightly on the barbed fitting_ Examinethe tube for

leaks or tears. Replacethe tube if damaged.

Detergent Siphening Check BaH

Occasionallycheck ball in detergent siphoning system may

become stuck from storage, dried soap, or minerals in water.

The check ball can be freed by performing the following:

HOT£E Before performing this procedure, be sure you are

wearing safety goggles as described below.

WARNING Risk of eye injury.

Spray could splash back or propel objects

resulting in serious injury.

o Always wear indirect vented (chemical splash) safety goggles

marked to comply with ANSi Z87.1 when using or in vicinity of

this equipment.

NEVERsubstitute safety glasses or dry-condition goggles for

indirect vented safety goggles.

2_

Shut off engine and turn off water supply.

ALWAYS point spray gun in a safe direction, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

A WARNIN6 The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

Keephigh pressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

ALWAYSpointspraygun in safedirection,pressred button

andsqueezesprayguntriggerto releasehighpressure,every

timeyou stop engine.

3. Remove detergent siphoning hose from barbed fitting

on pump.

4. Using a firm, blunt object 7/64" in diameter or smaller,

by at bast 1" long, such as an Allen wrench, slowly

insert the object into the barbed fitting until you meet

resistance. This resistance is the check ball.

5. Slowly push down until you fed the ball move slightly,

push no more than 1/8". Slight pressure may be

required to free the ball.

6. Repeatsteps 4 and 5 if necessary.

7. Reinstall detergent siphoning hose onto barb fitting.

8. Treat with PumpSaveras described in Protecting the

Pump during storage to prevent reoccurrence.

Check Spray Gan and Nezzie Extension

Examinehoseconnectionto spraygun and makesure it is

secure.Testtrigger by pressingit and makingsure it springs

backinto placewhenyou releaseit. Do not depressredbutton

andtest trigger. You shouldnot be ableto presstrigger. Replace

spraygun immediatelyif it fails any of thesetests.

Spray Tip Maintenance

A pulsing sensation felt while squeezingthe spray gun

trigger may becaused by excessive pump pressure. The

principal cause of excessivepump pressure is a spray tip

clogged or restricted with foreign materials, such as dirt, etc.

To correct the problem, immediately clean the spray tip

following these instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction, press red

button and squeezespray gun trigger to releaseretained

high water pressure.

& WARNING The high pressure stream of water that

this equipment produces could cut through skin

and its underlying tissues, resulting in serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which could result in

serious injury.

Keephigh pressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

ALWAYSpointspraygun in safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyou stopengine.

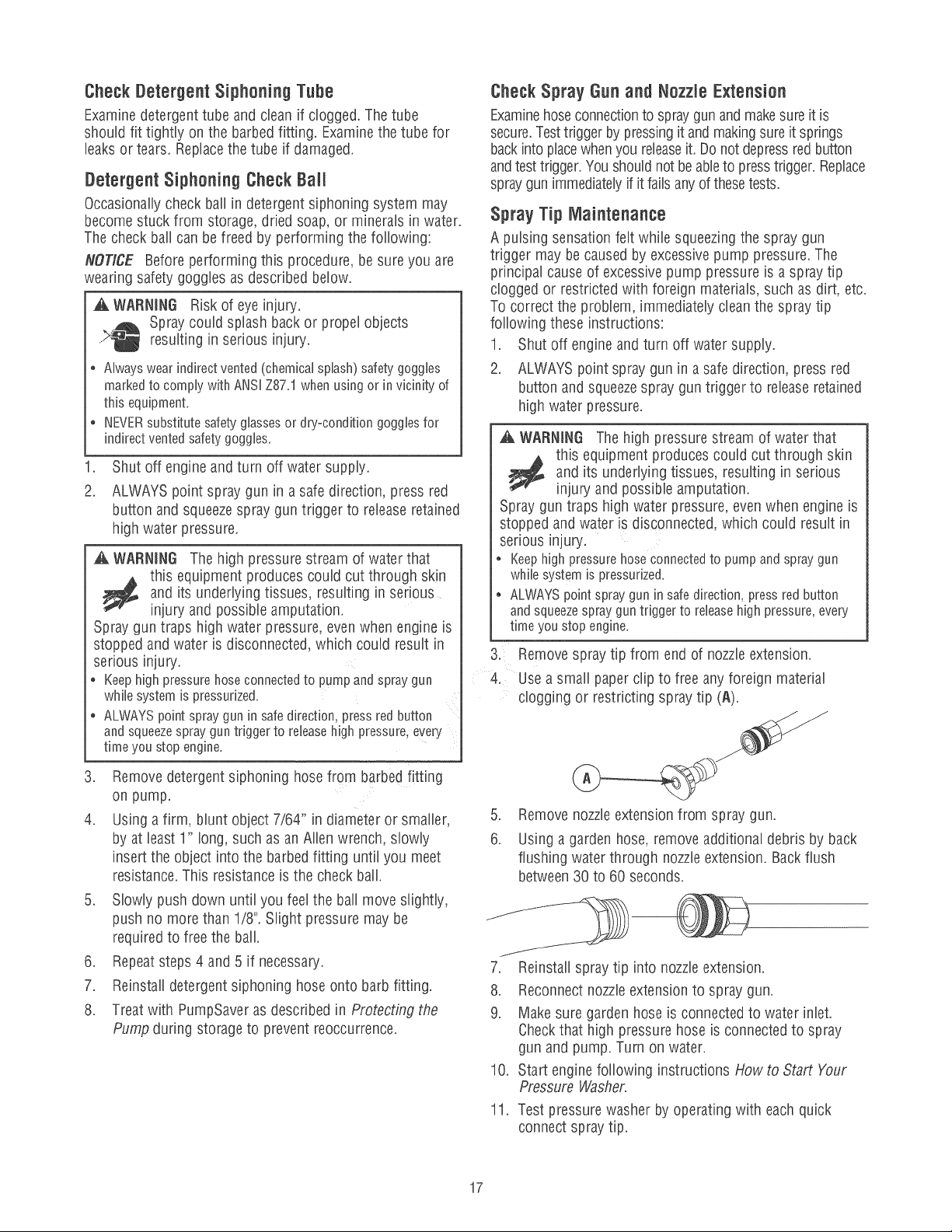

3. Remove spray tip from end of nozzleextension.

4. Use a small paper clip to free any foreign material

clogging or restricting spray tip (A).

5. Remove nozzleextension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Backflush

between30 to 60 seconds.

7. Reinstall spray tip into nozzle extension.

8. Reconnect nozzle extensionto spray gun.

9. Make sure garden hose is connectedto water inlet,

Checkthat high pressure hose is connectedto spray

gun and pump. Turn on water.

10. Start engine following instructions How to Start Your

Pressure Washer.

11. Test pressurewasher by operating with each quick

connect spray tip.

17

Loading ...

Loading ...

Loading ...