SAFETY PRECAUTIONS

Please read the following before servicing your refrigerator.

1. Check if electric leakage occurs in the set.

2. When servicing current applying parts, unplug prior to

servicing.

3. If testing with power on, wear rubber gloves to prevent

electric shock.

4. Be sure to check regular current, voltage, and capacity.

5. Don't touch metal products in a cold freezer

compartment with wet hands. It may cause frostbite or

other injury.

6. Prevent water flowing to electric elements in mechanical

parts.

7. When tilting the set, remove any materials on the set,

especially thin plate type (ex,: glass plates or books.)

8. When servicing evaporator part, wear cotton gloves to

prevent injury by sharp fins of the evaporator.

9. Do not open the sealed refrigeration system. It could

cause injury or pollute the air. Leave this job to an

autherized servicer with the appropriate refrigerant

recovery equipment.

SERVICING PRECAUTIONS

AIR RECHARGING IN COMPRESSOR

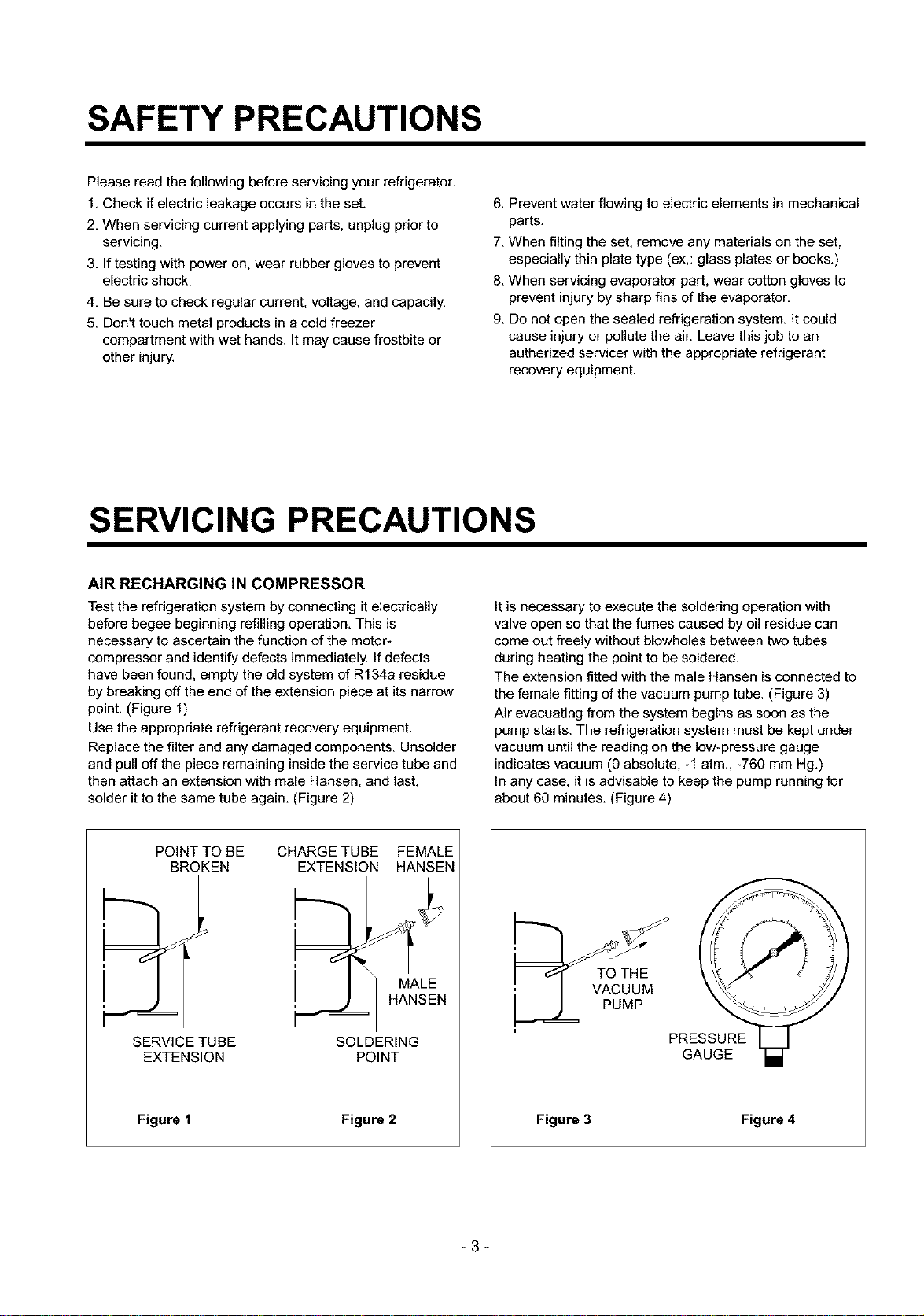

Test the refrigeration system by connecting it electrically

before begee beginning refilling operation. This is

necessary to ascertain the function of the motor-

compressor and identify defects immediately. If defects

have been found, empty the old system of R134a residue

by breaking off the end of the extension piece at its narrow

point. (Figure 1)

Use the appropriate refrigerant recovery equipment.

Replace the filter and any damaged components. Unsolder

and pull off the piece remaining inside the service tube and

then attach an extension with male Hansen, and last,

solder it to the same tube again. (Figure 2)

It is necessary to execute the soldering operation with

valve open so that the fumes caused by oil residue can

come out freely without blowholes between two tubes

during heating the point to be soldered.

The extension fitted with the male Hansen is connected to

the female fitting of the vacuum pump tube. (Figure 3)

Air evacuating from the system begins as soon as the

pump starts. The refrigeration system must be kept under

vacuum until the reading on the low-pressure gauge

indicates vacuum (0 absolute, -1 atm. -760 mm Hg.)

In any case, it is advisable to keep the pump running for

about 60 minutes. (Figure 4)

POINT TO BE CHARGE TUBE FEMALE

BROKEN EXTENSION HANSEN

MALE

HANSEN

SERVICE TUBE SOLDERING

EXTENSION POINT

Figure 1 Figure 2

PRESSURE

GAUGE

Figure 3 Figure 4

-3-

Loading ...

Loading ...

Loading ...