Loading ...

Loading ...

Loading ...

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult.

After each use, ensure ON/STOP

switch is in the STOP position, then

clean all sawdust from the guide bar

and sprocket hole.

To maintain guide bar:

• Move ON/STOP switch to STOP.

• Loosen and remove chain brake

nuts and chain brake. Remove bar

and chain from saw.

• Clean the oil holes and bar groove

after each 5 hours of operation.

• Burring of guide bar rails is a normal

process of rai! wear. Remove these

burrs with a flat file.

• When rail top is uneven, use a fiat

file to restore square edges and sides.

_j_ File Rail Edges_- _

and Sides

Square

Worn Groove Correct Groove

Replace guide bar when the groove is

worn, the guide bar is bent or cracked,

or when excess heating or burring of

the rails occurs. If replacement is nec-

essary, use only the guide bar speci-

fied for your saw in the repair parts list

or on the decal located on the chain

saw.

CHECK FUEL MIXTURE LEVEL

• See FUELING ENGINE under the OP-

ERATION section.

LUBRICATION

Bar Oil

Fill Cap

• See GUIDE BAR AND CHAIN OIL un-

der the OPERATION section.

INSPECT AND CLEAN UNIT AND

DECALS

• After each use, inspect complete unit

for loose or damaged parts. Clean

the unit and decals using a damp

cloth with a mild detergent.

• Wipe off unit with a clean dry cloth.

CHECK CHAIN BRAKE

• Bee CHAIN BRAKE in the OPERATION

section.

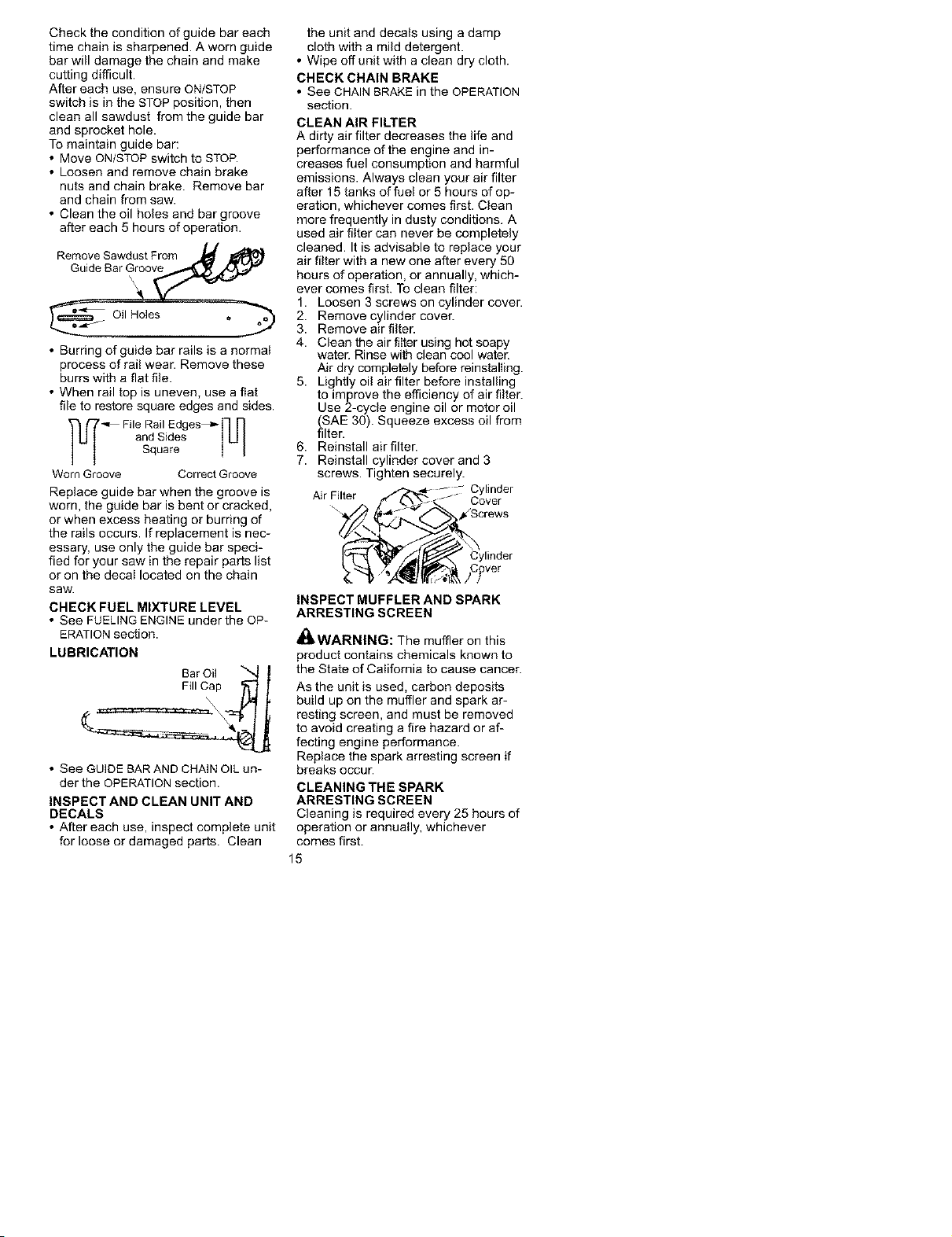

CLEAN AIR FILTER

A dirty air filter decreases the life and

performance of the engine and in-

creases fuel consumption and harmful

emissions. Always clean your air filter

after 15 tanks of fuel or 5 hours of op-

eration, whichever comes first. Clean

more frequently in dusty conditions. A

used air filter can never be completely

cleaned. It is advisable to replace your

air filter with a new one after every 50

hours of operation, or annually, which-

ever comes first. To clean filter:

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean the air filter using hot soapy

water. Rinse with clean cool water.

Air dry completely before reinstalling.

5. Lightly oil air filter before installing

to improve the efficiency of air filter.

Use 2-cycle engine oil or motor oil

(SAE 30). Squeeze excess oil from

filter.

6. Reinstall air filter.

7. Reinstall cylinder cover and 3

screws. Tighten securely.

Iinder

Air Filter Cover

"Screws

Cylinder

Clover

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

zIL _____ __ =

_WARNING: The muffler on this

product contains chemicals known to

the State of California to cause cancer.

As the unit is used, carbon deposits

build up on the muffler and spark ar-

resting screen, and must be removed

to avoid creating a fire hazard or af-

fecting engine performance.

Replace the spark arresting screen if

breaks occur.

CLEANING THE SPARK

ARRESTING SCREEN

Cleaning is required every 25 hours of

operation or annually, whichever

comes first.

15

Loading ...

Loading ...

Loading ...