Loading ...

Loading ...

Loading ...

OPERAI=ION

TO USE WEIGHT TRANSFER SYSTEM

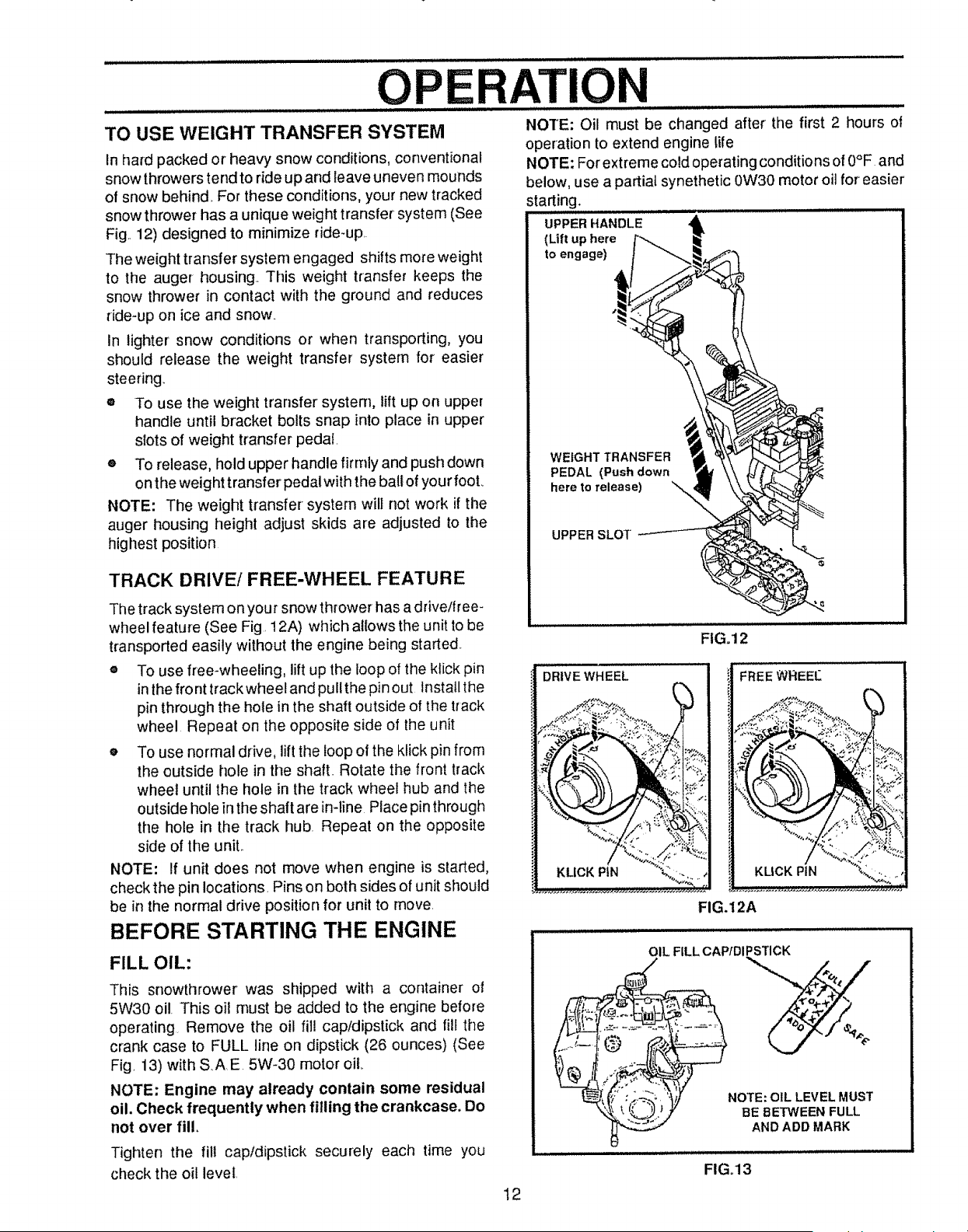

In hard packed or heavy snow conditions, conventional

snow throwers tend to ride up and leave uneven mounds

of snow behind. For these conditions, your new tracked

snow thrower has a unique weight transfer system (See

Fig,, 12) designed to minimize dde-up,.

The weight transfer system engaged shifts more weight

to the auger housing. This weight transfer keeps the

snow thrower in contact with the ground and reduces

ride-up on ice and snow..

In lighter' snow conditions or when transporting, you

should release the weight transfer system for easier

steering.

® To use the weight transfer system, lift up on upper

handle until bracket bolts snap into place in upper

slots of weight transfer pedal.

e To release, hold upper handle firmly and push down

on the weight transfer pedal with the ball of your fool

NOTE: The weight transfer system will not work if the

auger housing height adjust skids are adjusted to the

highest position

TRACK DRIVE/FREE-WHEEL FEATURE

The track system on your snow thrower has adrive/free_

wheel feature (See Fig, 12A) which allows the unit to be

transported easily without the engine being started..

® To use free-wheeling, lift up the loop of the kfick pin

in the front track wheel and pull the pin out Install the

pin through the hole in the shaft outside of the track

wheel Repeat on the opposite side of the unit

o To use normal drive, lift the loop of the klick pin from

the outside hole in the shaft.. Rotate the front track

wheel until the hole in the track wheel hub and the

outside hole in the shaft are in-line Place pin through

the hole in the track hub. Repeat on the opposite

side of the unit,.

NOTE: If unit does not move when engine is started,

check the pin locations, Pins on both sides of unit should

be in the normal drive position for unit to move,

BEFORE STARTING THE ENGINE

FILL OIL:

This snowthrower was shipped with a container of

5W30 oi!. This oil must be added to the engine before

operating Remove the oil fii! cap/dipstick and fill the

crank case to FULL line on dipstick (26 ounces) (See

Fig, 13) with SAE 5W-30 motor oil

NOTE: Engine may already contain some residual

oil. Check frequently when filling the crankcase. Do

not over fill.

Tighten the fill cap/dipstick securely each time you

check the oil level,

NOTE: Oil must be changed after the first 2 hours of

operation to extend engine life

NOTE: For extreme cold operating conditions of 0°F and

below, use a partial synethetic 0W30 motor oil for' easier

starting. ........................

UPPER HANDLE

(Lift up here

to engage)

WEIGHT TRANSFER

PEDAL (Push down

here to release)

UPPER SLOT

DRIVE WHEEL

FIG. 12

FREEWREEt_

KUCK PIN

FIG.12A

OIL FILL CAPtDIPSTICK

%

NOTE: OIL LEVEL MUST

BE BETWEEN FULL

AND ADD MARK

12

FIGo13

Loading ...

Loading ...

Loading ...