Loading ...

Loading ...

Loading ...

Perform hydrostatic pressure test:

See pages 2 and 3 for boiler feature locations.

1. Install air vent in relief valve tapping.

2. Plug supply and return tappings.

3. Install the boiler drain valve shipped with boiler.

4. Fill boiler.

5. Vent all air.

6. Pressure test boiler at 1½ times working pressure.

Do not leave boiler unattended. Cold water ll can ex-

pand and damage cast iron, resulting in severe personal

injury, death or substantial property damage.

7. Check for maintained gauge pressure for at least 10 minutes.

Visually check for leaks if gauge pressure drops.

8. Drain boiler. Repair leaks if found.

Do not use petroleum-based sealing compounds to

repair leaks. Damage to system components can result,

causing property damage.

9. Retest boiler aer repairing leaks.

10. Remove air vent and plugs. Reinstall relief valve.

Boiler preparation

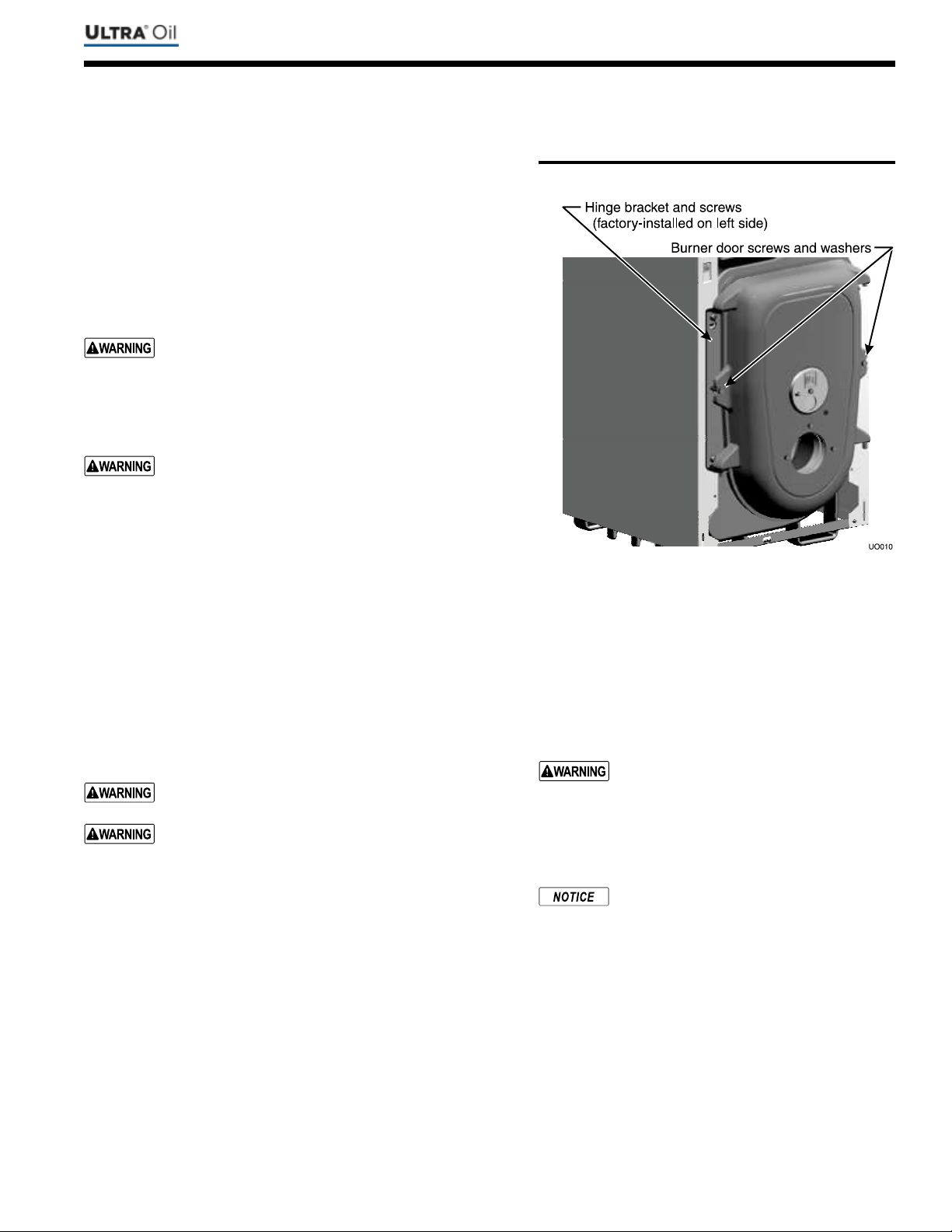

e boiler is shipped with the burner door hinged on the le side. e

hinge bracket can be relocated to the right side if desired. See Figure 4.

1. Remove jacket front panel.

2. Remove and retain burner door screws and washers used to fasten

the burner door to the front section (one on each side of door).

3. Carefully li the burner door so the door pins li out of the hinge

bracket.

4. Set the burner door aside temporarily.

e burner door is heavy. Handle carefully to avoid

potential for personal injury.

Do not damage the burner door insulation when han-

dling.

5. e hinge bracket has keyhole slots. Loosen the two (2) screws

securing the hinge bracket to the front section. Remove the hinge

bracket.

6. Loosen the two (2) screws on the opposite side. Place the hinge

bracket on that side and tighten the two screws to secure the

bracket. Also tighten the two (2) screws on the other side.

7. Carefully li the burner door and position so the door pins slide

into the hinge bracket holes. e lower pin is longer than the up-

per. So align the lower pin, then the upper.

8. Replace burner door screws and washers used to fasten the burner

door to the front section (one on each side of door).

Prepare boiler location(continued)

1. Check for secure placement of insulation on burner

door.

2. Check for secure placement of combustion chamber

oor blanket.

3. Visually check b

urner mounting door seal.

Verify gas-tight seal to prevent possible ue

gas leakage and carbon monoxide emissions,

which can lead to severe personal injury or

death.

e Ultra Oil boiler is shipped with baes

installed for improved eciency. A stainless

steel shipping strap is installed to keep baes

in place during shipment. is band may stay

in place until maintenance is required. is

band does not have to be replaced aer its

removal.

Part number 550-143-013/0621

11

Series 3

Loading ...

Loading ...

Loading ...