Loading ...

Loading ...

Loading ...

8. PREPARING THE WOOD LATHE

10. BASIC WOOD TURNING

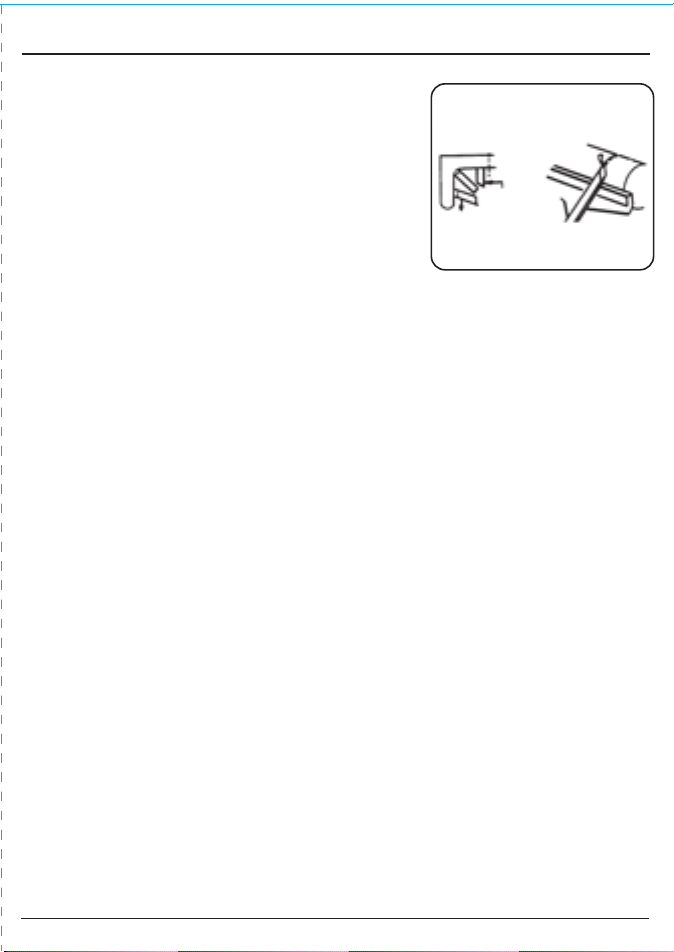

10.4 KNOWING WHEN TO CUT AND WHEN TO

SCRAPE - FIG. 22

There are two different approaches to the work when

turning. The first is towards a circumference of the

workpiece (eg. When turning down the outer surface of a

cylinder or the inner wall of a hollow round box). Using

this method, the surface being turned travels under the

edge of the chisel like an endless belt. The second

approach is towards the diameter of the workpiece (as

when turning the face when faceplate turning, or the side

of a large shoulder when spindle turning) using this

method the surface being turned rotates like a disc under

the chisel edge. Some jobs will require both methods

being used.

Either a cutting or scraping action may be used when the

method used is towards the circumference – the shaving

will come off like the peel from a potato.

Only scraping can be used when the method used is

towards the diameter. The reason for this is obvious when

you consider that faceplate turning nearly always requires

the removal of wood across the grain. Wood does not

peel easily when turning across the grain and any attempt

made to use cutting methods will probably result in

damage to the workpiece and the chisel being thrown by

the workpiece.

It therefore follows that a cutting action is used for

general spindle turning operations, while the majority of

faceplate turning is carried out by the scraping method.

When both methods are to be used, you will have to

judge by the feel of the workpiece when to stop cutting

and start scraping. NEVER try to cut when it becomes

difficult to hold the chisel against the wood grain.

FIG.22

Diameter

Approach

Circumference

Approach

FIG.5

FIG.6

8.5 REMOVAL - FIGS. 5 - 6

When the need arises to remove the spurs, use the

ejection pin to push out the live centre from the

tailstock by inserting it down the centre of the tailstock

handwheel hole .

The drive spur is removed using the ejection pin and

the spindle holding wrench . Using the wrench to hold

the spindle on the flats, insert the ejection pin into the

hole in the side of the thread protection cap . Undo

the cap which will force the spur out of the spindle.

17

12

Loading ...

Loading ...

Loading ...