Loading ...

Loading ...

Loading ...

28

REACH-INS & ROLL-INS

OPERATIONS MANUAL

Using the small holes in the plate as a template, drill 1/8 pilot

holes in the bottom of the cabinet. (Note: drill only until you

penetrate the metal bottom of the cabinet. Do not continue

to drill into the insulation, or you may damage the cabinet.)

Secure the caster support plate assembly to the cabinet with a

sheet metal screw in each of the drilled holes. Tighten the 1/2”

bolts. Repeat these steps to attach the other plate assembly to

the opposite end of the cabinet.

Check that both plates are secure and that the casters turn

and swivel freely. Carefully lift the cabinet upright and double

check that the caster support plates are secure and the cabinet

is stable. Wait at least 3 hours before turning the refrigeration

system back on, and at least another 30 minutes for the cabinet

to come down to temperature and stabilize, before reloading

with product.

MOUNTING CASTER SUPPORT PLATES

If casters on a cabinet are not properly maintained and tight-

ened, or if the unit is excessively overloaded and moved around,

the threaded inserts in the bottom of the cabinet can become

stripped, twisted or collapsed. If this occurs and the stem cast-

ers cannot be mounted securely, rigid caster support plates can

be fitted to provide the strength needed to safely use your cabi-

net. Each caster support plate assembly is made of heavy gauge

galvanized steel, with (2) casters permanently welded to it, for

maximum rigidity. The plate has a series of holes that will allow

you to fasten the plate assembly to the bottom of the cabinet

with sheet metal screws and bolts. Contact the factory to obtain

the correct parts for your model.

IMPORTANT NOTE: Always wear proper work gloves and

use appropriate safety equipment. You may CAREFULLY

lay the cabinet on its back, but only FOR A BRIEF PERIOD

OF TIME. Caution must be taken to ensure you DO NOT

DAMAGE the back or side panels, as well as the copper

tubing and refrigeration components located on top of

your cabinet. The cabinet must be properly blocked, to

allow room to get your hands in to lift without damaging

the cabinet or crushing the end panels. DO NOT PLUG-IN

OR OPERATE THE REFRIGERATION SYSTEM FOR AT

LEAST THREE (3) HOURS AFTER THE UNIT HAS BEEN

RETURNED TO AN UPRIGHT POSITION, AS THIS CAN

DAMAGE THE COMPRESSOR.

To install caster support plate assemblies, you will need a 3/4”

open end wrench (or a large adjustable wrench), a drill with a

1/8” bit and a Phillips bit (or a Phillips-Head screwdriver) plus

work gloves. A 1/2-13 thread tap is also recommended, to repair

any damage to the threaded inserts in the cabinet. Unload all

product and carefully lay the cabinet on its back. Remove the old

stem casters by unscrewing them from the cabinet. If a caster or

threaded insert has been stripped or cross-threaded, it may be

necessary to use a wrench to loosen the caster.

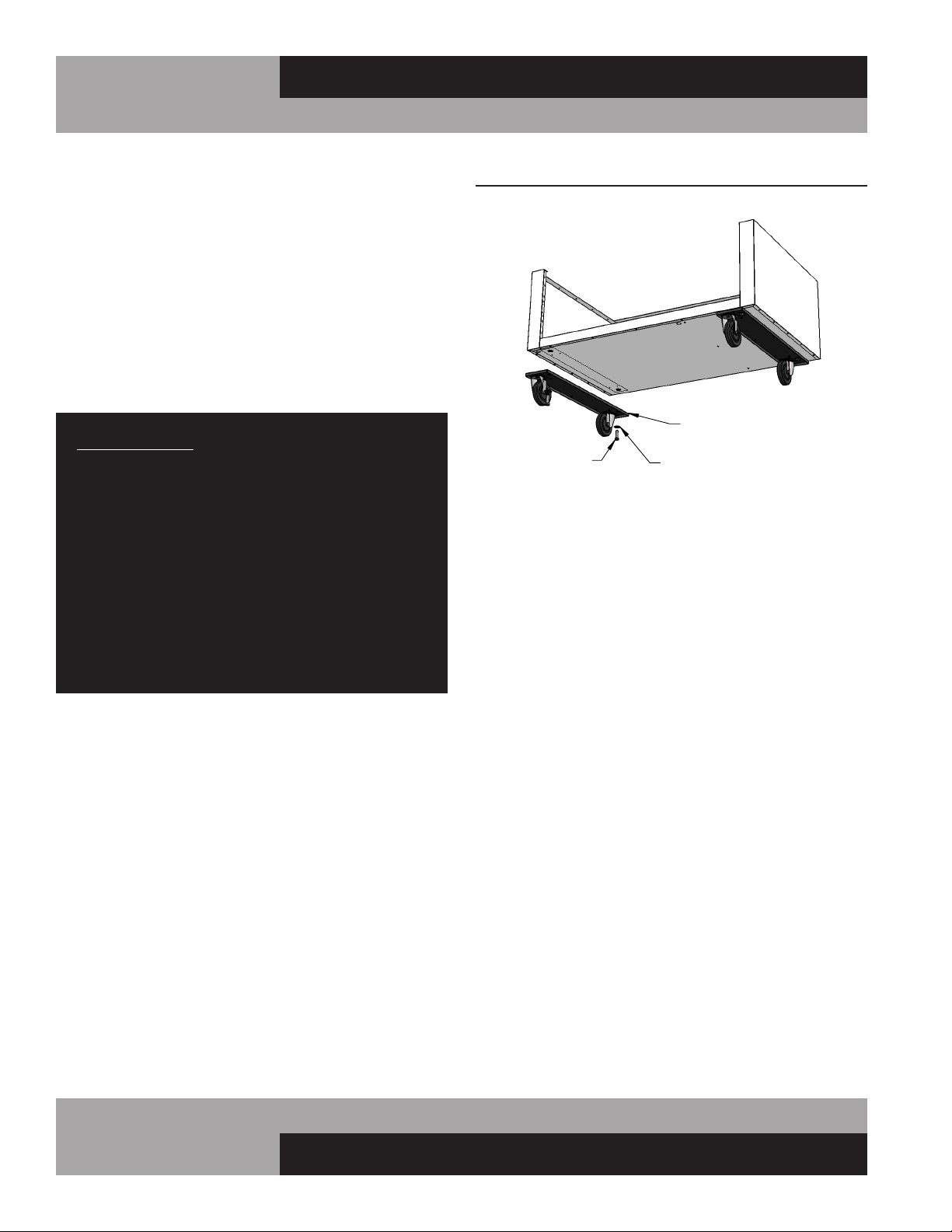

Hold one of the support plate assemblies under the cabinet as

shown (see Figure 14). Position it so the slotted holes at the end

of the plate line up with the threaded inserts in the bottom of the

cabinet (where the stem casters were attached). Attach the plate

assembly to the cabinet by putting a 1/2” x 1-3/4” long bolts and

flat washer through the slot in the support plate and screwing

into each of the threaded inserts in the bottom of the cabinet.

Snug the bolts down, but do not tighten them completely. If

one of the threaded inserts is stripped or damaged, a thread tap

should be used to clean the threads.

FIGURE 14: Caster Support Plates

1/2-13 BOLT

(2 PER PLATE)

FLAT WASHER

(2 PER PLATE)

SUPPORT ASSEMBY

Loading ...

Loading ...

Loading ...