Loading ...

Loading ...

Loading ...

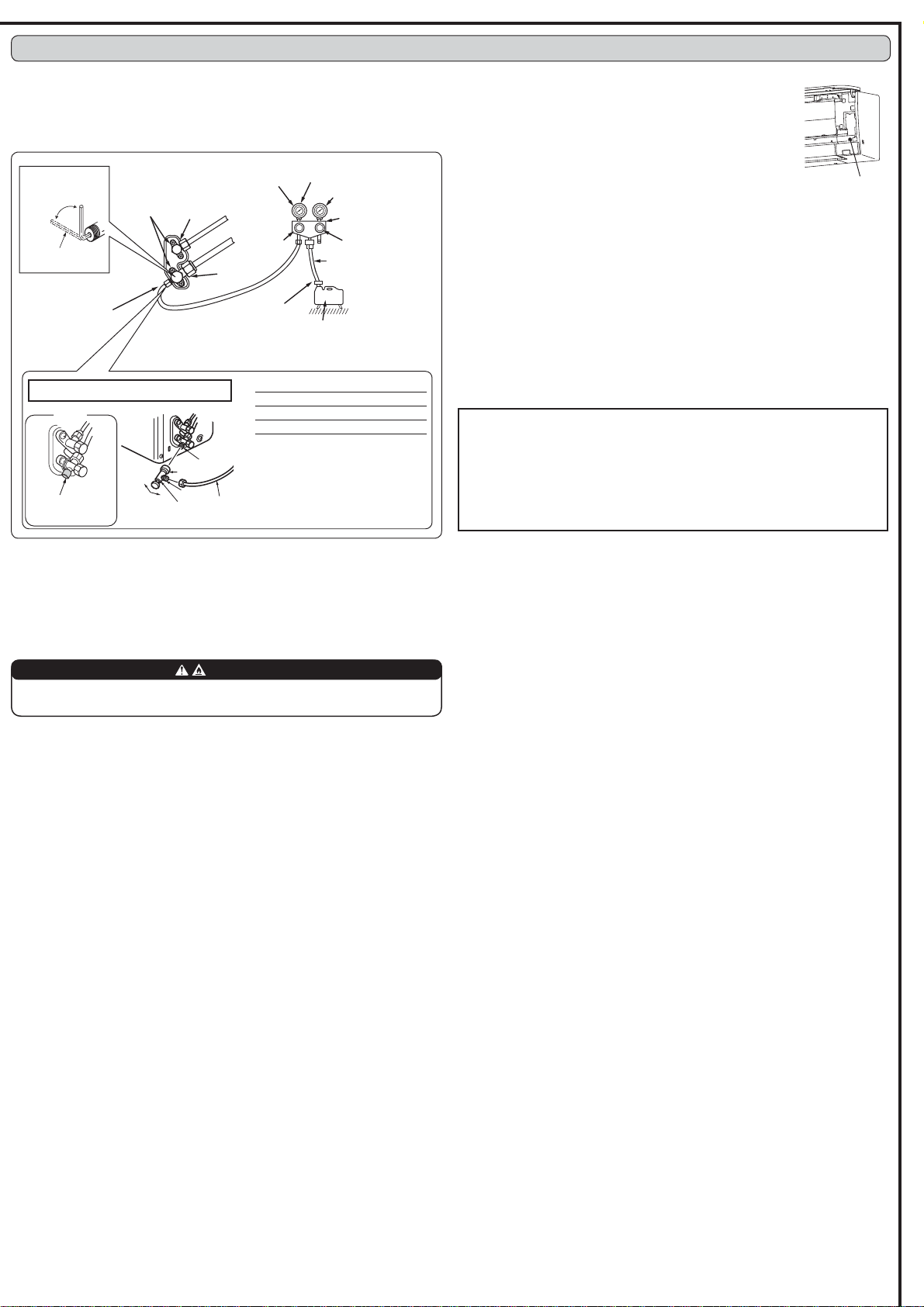

4-1. PURGING PROCEDURES AND LEAK TEST

1) Remove service port cap of stop valve on the side of the outdoor unit gas pipe. (The stop

valves are fully closed and covered in caps in initial state.)

2) Connect gauge manifold valve and vacuum pump to service port of stop valve on the gas

pipe side of the outdoor unit.

4-2. TEST RUN

1) Insert power supply plug into the power outlet and/or turn on the

breaker.

2) Press the E.O. SW once for COOL, and twice for HEAT operation.

Test run will be performed for 30 minutes. If the upper lamp of the

operation indicator blinks every 0.5 seconds, inspect the indoor/

outdoor unit connecting wire (A) for mis-wiring. After the test run,

emergency mode (set temperature 24ºC) will start.

7RVWRSRSHUDWLRQSUHVVWKH(26:VHYHUDOWLPHVXQWLODOO/('

lamps turn off. Refer to operating instructions for details.

4) Checking the remote (infrared) signal reception

3UHVV WKH 2))21 EXWWRQ RQ WKH UHPRWH FRQWUROOHU DQG

check that an electronic sound is heard from the indoor unit.

Press the OFF/ON button again to turn the air conditioner off.

2QFHWKH FRPSUHVVRU VWRSV WKH UHVWDUW SUHYHQWLYH GHYLFH

operates so the compressor will not operate for 3 minutes to

protect the air conditioner.

Stop valve for

GAS

Stop valve cap

(Torque 19.6 to

1P

WRNJIFP

Vacuum pump (or the vacuum

pump with the function to

SUHYHQWWKHEDFNÀRZ

Gauge manifold valve

(for R32, R410A)

Compound pressure gauge

(for R32, R410A)

–0.101 MPa

(

–760 mmHg)

Handle

Low

Handle High

Adapter for

preventing the

EDFNÀRZ

Charge hose

(for R32, R410A)

*Close

*Open

Hexagonal wrench

Precautions when using the control valve

When attaching the control valve

to the service port, valve core may

deform or loosen if excess pressure

is applied. This may cause gas leak.

Service port

%RG\

Close

<R32>

Open

Control

valve

A

When attaching the control valve to

the service port, make sure that the

valve core is in closed position, and

WKHQ WLJKWHQ SDUW $ 'R QRW WLJKWHQ

part A or turn the body when valve

core is in open position.

Service port cap

(Torque 13.7 to

1P140 to

180 kgfcm)

*4 to 5 turns

3) Run the vacuum pump. (Vacuumize until 500 microns is achieved.)

4) Check the vacuum with gauge manifold valve, then close gauge manifold valve, and stop

the vacuum pump.

5) Leave as it is for one or two minutes. Make sure pointer gauge manifold valve remains

LQWKHVDPHSRVLWLRQ&RQ¿UPWKDWSUHVVXUHJDXJHVKRZV±03D>*DXJH@±

mmHg).

6) Remove gauge manifold valve quickly from service port of stop valve.

Stop valve

IRU/,48,'

Caution:

$IWHUWHVWUXQRUUHPRWHVLJQDOUHFHSWLRQFKHFNWXUQRIIWKHXQLWZLWKWKH(26:RU

the remote controller before turning off the power supply. Not doing so will cause the

unit to start operation automatically when power supply is resumed.

To the user

$IWHULQVWDOOLQJWKHXQLWPDNHVXUHWRH[SODLQWKHXVHUDERXWDXWRUHVWDUWIXQFWLRQ

,I DXWR UHVWDUW IXQFWLRQ LV XQQHFHVVDU\ LW FDQ EH GHDFWLYDWHG &RQVXOW WKH VHUYLFH

representative to deactivate the function. Refer to the service manual for details.

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN

Pressure gauge

(for R32, R410A)

Emergency operation

switch (E.O. SW)

Charge

hose

Make sure to re-

place the cap after

the operation.

4-4. EXPLANATION TO THE USER

8VLQJWKH23(5$7,1*,16758&7,216H[SODLQWRWKHXVHUKRZWRXVHWKHDLUFRQGLWLRQHU

KRZWRXVHWKHUHPRWHFRQWUROOHUKRZWRUHPRYHWKHDLU¿OWHUVKRZWRFOHDQSUHFDXWLRQV

for operation, etc.).

5HFRPPHQGWKHXVHUWRUHDGWKH23(5$7,1*,16758&7,216FDUHIXOO\

7RDYRLGULVNRI¿UHPDNHVXUHWKDWWKHUHDUHQRÀDPPDEOHKD]DUGVRULJQLWLRQ

risks before opening the stop valves.

7) After refrigerant pipes are connected and evacuated, fully open all stop valves on both

sides of gas pipe and liquid pipe. Operating without fully opening lowers the performance

and this causes trouble.

5HIHUWRDQGFKDUJHWKHSUHVFULEHGDPRXQWRIUHIULJHUDQWLIQHHGHG%HVXUHWRFKDUJH

slowly with liquid refrigerant. Otherwise, composition of the refrigerant in the system may

be changed and affect performance of the air conditioner.

9) Tighten cap of service port to obtain the initial status.

10) Leak test

4-3. AUTO RESTART FUNCTION

This product is equipped with an auto restart function. When the power supply is stopped

during operation, such as during blackouts, the function automatically starts operation in

the previous setting once the power supply is resumed. (Refer to the operating instructions

for details.)

WARNING

Loading ...

Loading ...