Loading ...

Loading ...

Loading ...

ASSEMBLY

INSTALLING THE GUIDE BAR AND

SAW CHAIN

CAUTION: Sharpchain. Always

wear protective gloves when handling

the chain. The chain is sharp and can cut

you when it is not running.

2_WARNING: Sharp moving chain.

To prevent accidental operation, ensure

that battery is removed from the tool

before performing the fotlowing

operations. Failure to do this could result in

serious personal injury.

The saw chain (5) and guide bar (4) are

packed separately in the carton. The chain

has to be attached to the bar, and both must

be attached to the body of the tool.

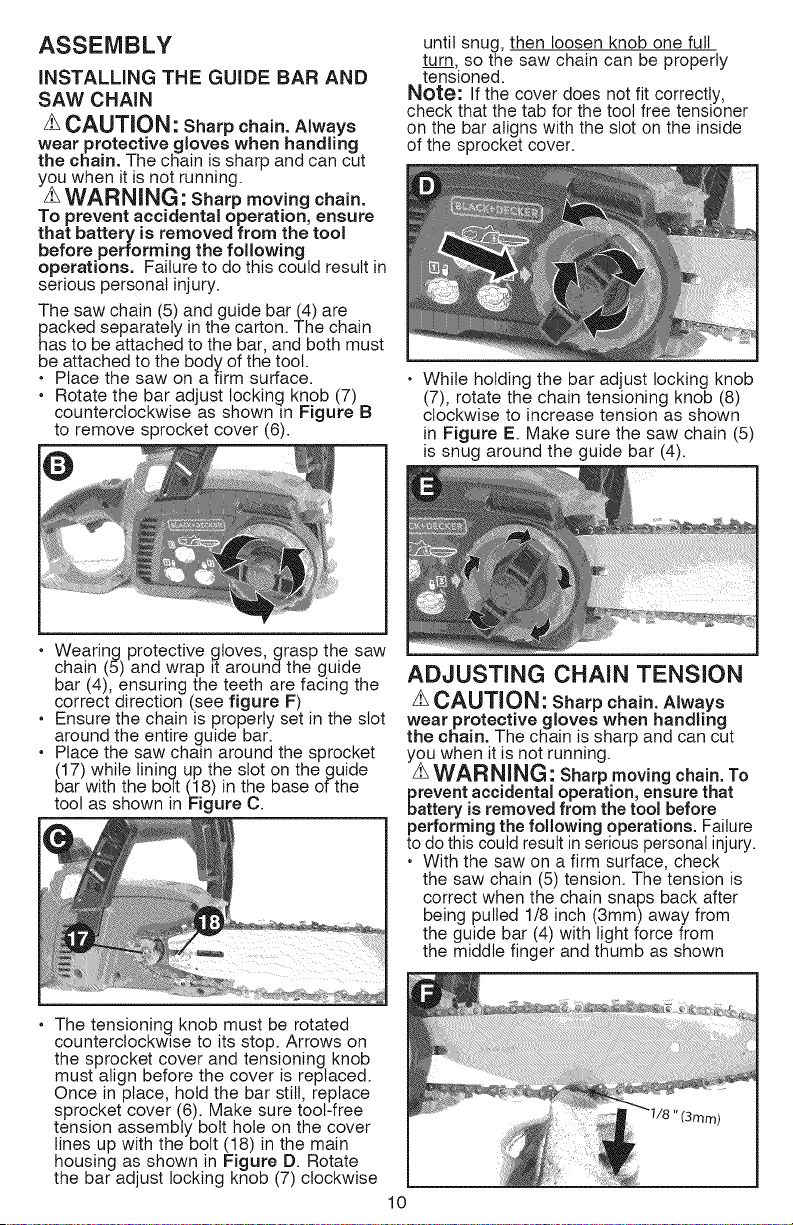

• Place the saw on a firm surface.

• Rotate the bar adjust locking knob (7)

counterclockwise as shown m Figure B

to remove sprocket cover (6).

until snug, then loosen knob one full

turn, so the saw chain can be properly

tensioned.

Note: If the cover does not fit correctly,

check that the tab for the tool free tensioner

on the bar aligns with the slot on the inside

of the sprocket cover.

While holding the bar adjust locking knob

(7), rotate the chain tensioning knob (8)

clockwise to increase tension as shown

in Figure E. Make sure the saw chain (5)

is snug around the guide bar (4).

• Wearing protective gloves, grasp the saw

chain (5) and wrap it around the guide

bar (4), ensuring the teeth are facing the

correct direction (see figure F)

• Ensure the chain is properly set in the slot

around the entire guide bar.

Place the saw chain around the sprocket

(17) while lining up the slot on the guide

bar with the bolt (18) in the base of the

tool as shown in Figure C.

ADJUSTING CHAIN TENSION

zLCAUTION: Sharp chain. Always

wear protective gloves when handling

the chain. The chain is sharp and can cut

you when it is not running.

zLWARNING: Sharp moving chain. To

prevent accidental operation, ensure that

battery is removed from the tool before

performing the following operations. Failure

to do this could result in serious personal injury.

• With the saw on a firm surface, check

the saw chain (5) tension. The tension is

correct when the chain snaps back after

being pulled 1/8 inch (3mm) away from

the guide bar (4) with light force from

the middle finger and thumb as shown

• The tensioning knob must be rotated

counterclockwise to its stop. Arrows on

the sprocket cover and tensioning knob

must align before the cover is replaced.

Once in place, hold the bar still, replace

sprocket cover (6). Make sure tool-free

tension assembly bolt hole on the cover

lines up with the bott (18) in the main

housing as shown in Figure D. Rotate

the bar adjust locking knob (7) clockwise

10

Loading ...

Loading ...

Loading ...