Loading ...

Loading ...

Loading ...

6

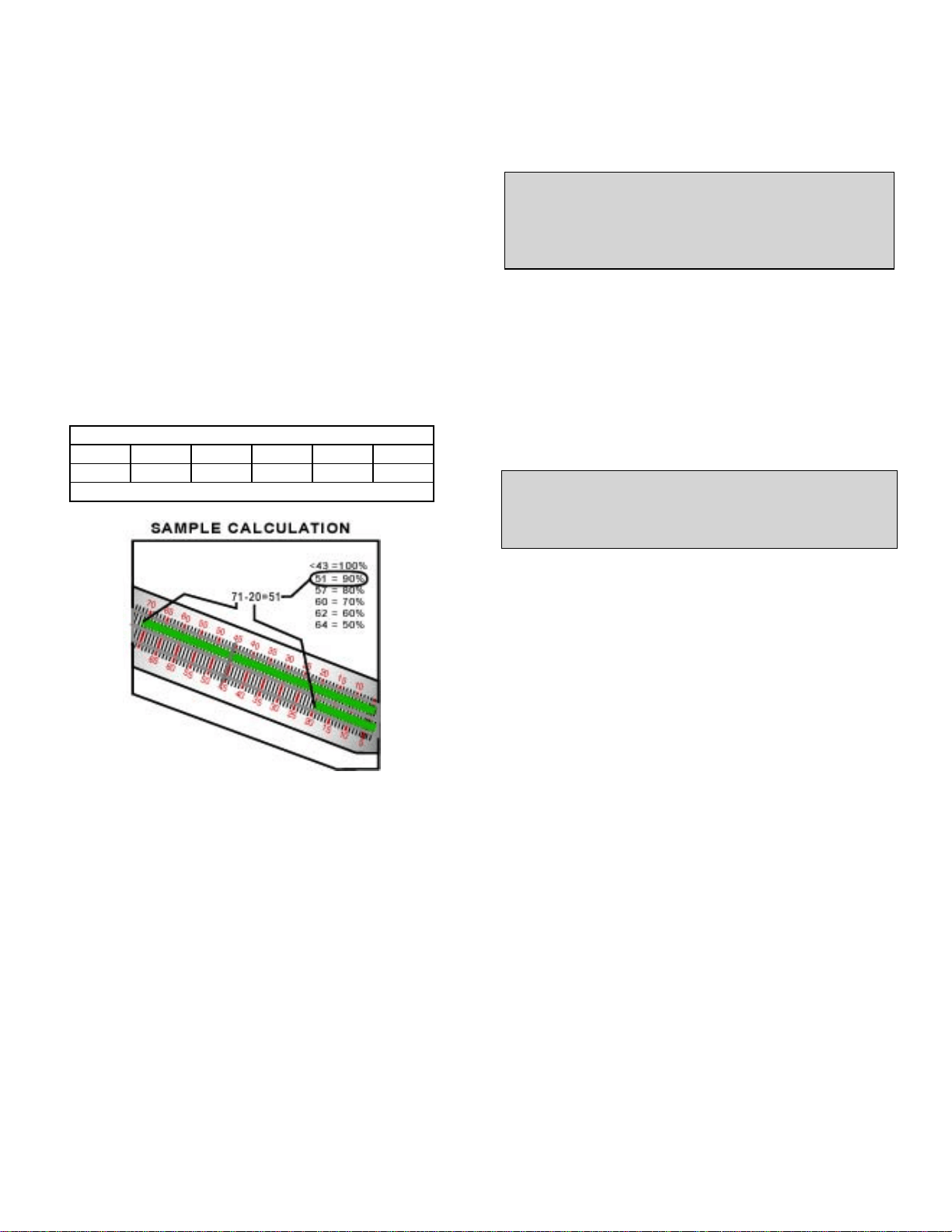

3.2 Checking Airflow

An inclined tube manometer is attached to the unit to

determine if the filters need replacing. It measures

negative static pressure between the blower inlet and the

HEPA filter outlet.

To check airflow:

• Remove any inlet or outlet ducting, but leave the top

and all filters in place. Make sure the unit is sitting

level.

• Turn the unit on high speed for at least 15 minutes.

Read the number values for the fluid levels in the

upper and lower tubes. The fluid levels are slanted.

Read the level at the center of both tubes.

• Subtract the lower tube number from the upper tube

number. Match this difference to the chart on the

manometer label to establish the percentage of clean

air flow.

Calculation

43 51 57 60 62 64

100% 90% 80% 70% 60% 50%

Percentage

Airflow on high speed with all filters clean and no ducting

is about 1400 CFM. The unit can be run with very dirty

filters and virtually no flow without harming the unit. The

operator’s decision to change filters should be based on

filter cost versus the unit’s filtering effectiveness. If

airflow is 700 CFM versus 1400 CFM, the unit will filter

particles from a space at half the rate. The operator must

judge if that is acceptable.

If the operator determines the filters should be changed

due to low airflow, it is most economical to change them

in the following order:

• Change the pad pre-filter (top) first. This is the least

expensive filter. Recheck the airflow. If the airflow is

acceptable, no other filters need to be changed.

• Change the pleated fabric filter (middle) second. It is

the second least expensive filter. Recheck the

airflow. If acceptable, the HEPA filter does not need

changing.

• If the airflow is still too low, the HEPA filter must be

changed.

4 Service

CAUTION: Servicing the Phoenix Guardian with its

high voltage circuitry presents a health hazard that

could result in death, serious bodily injury, and/or

property damage. Only qualified service people should

service this unit.

4.1 Warranty

A warranty certificate has been enclosed with this unit.

Read it before any repair is initiated. If a warranty repair

is required, call the factory first at 1-800-533-7533 for

warranty claim authorization and technical assistance.

4.2 Blower Motor Replacement

OCCASSIONALLY THE BLOWER MAY NOT START

ON LOW SPEED. IF THIS OCCURS, START THE

UNIT ON HIGH SPEED, THEN SWITCH IT TO LOW

SPEED.

The centrifugal blower has a PSC motor and internal

thermal overload protection. Follow the steps below to

change the motor:

1. Unplug the power cord.

2. Remove the top and all air filters.

3. Remove the wire nut that connects the blower’s

white lead to the wire harness. Disconnect the

motor’s green ground wire from the unit. Remove

the black and red wires from the switch.

4. Remove the four nuts that fasten the blower

mounting flanges to the base of the unit.

5. Lift the blower out of the unit.

6. Loosen the set screw that holds the impeller hub to

the motor shaft.

7. Lay the blower on its side, motor up.

8. Remove the 3 screws that fasten the motor support

brackets to the blower housing.

9. Lift out the motor with support brackets.

10. Remove the two screws (one at each motor end)

that hold the support brackets to the motor end

mounting rings.

11. Remove the six screws that hold the support

bracket halves together. Note which holes and slots

they were located in.

12. Reassembling with the new motor is the above

procedure reversed.

www.sylvane.com 1-800-934-9194

Loading ...

Loading ...