Loading ...

Loading ...

Loading ...

3. Ifthecuttingattachmentrotateswhentheengineidles,turnthe

idlespeedscrewcounterclockwise1/8ofaturnatatime(as

needed),toreduceidlespeed.

Checkingthefuel,cleaningtheairfilter,andadjustingtheidlespeed

shouldsolvemostengineproblems.Ifnotandallofthefollowing

aretrue:

• theenginewillnotidle

• theenginehesitatesorstallsonacceleration

• thereisalossofenginepower

Havethecarburetoradjustedbyanauthorizedservicedealer.

ROCKER ARM CLEARANCE

_I ARNING: TOavoid serious personal injury, alwaysturn your

tr mmer off and a ow t to coo before you c eanor manta n t.

This requires disassembly of the engine. If you feel unsure or

unqualified to perform this, take the unit to a Sears or other qualified

service center.

NOTE: Inspect the valve to rocker arm clearance with a feeler

gauge after the first 25 hours of operation and then every

25 hours of operation thereafter.

• The engine must be cold when checking or adjusting the valve

clearance.

• This task should be performed inside in a clean, dust free area.

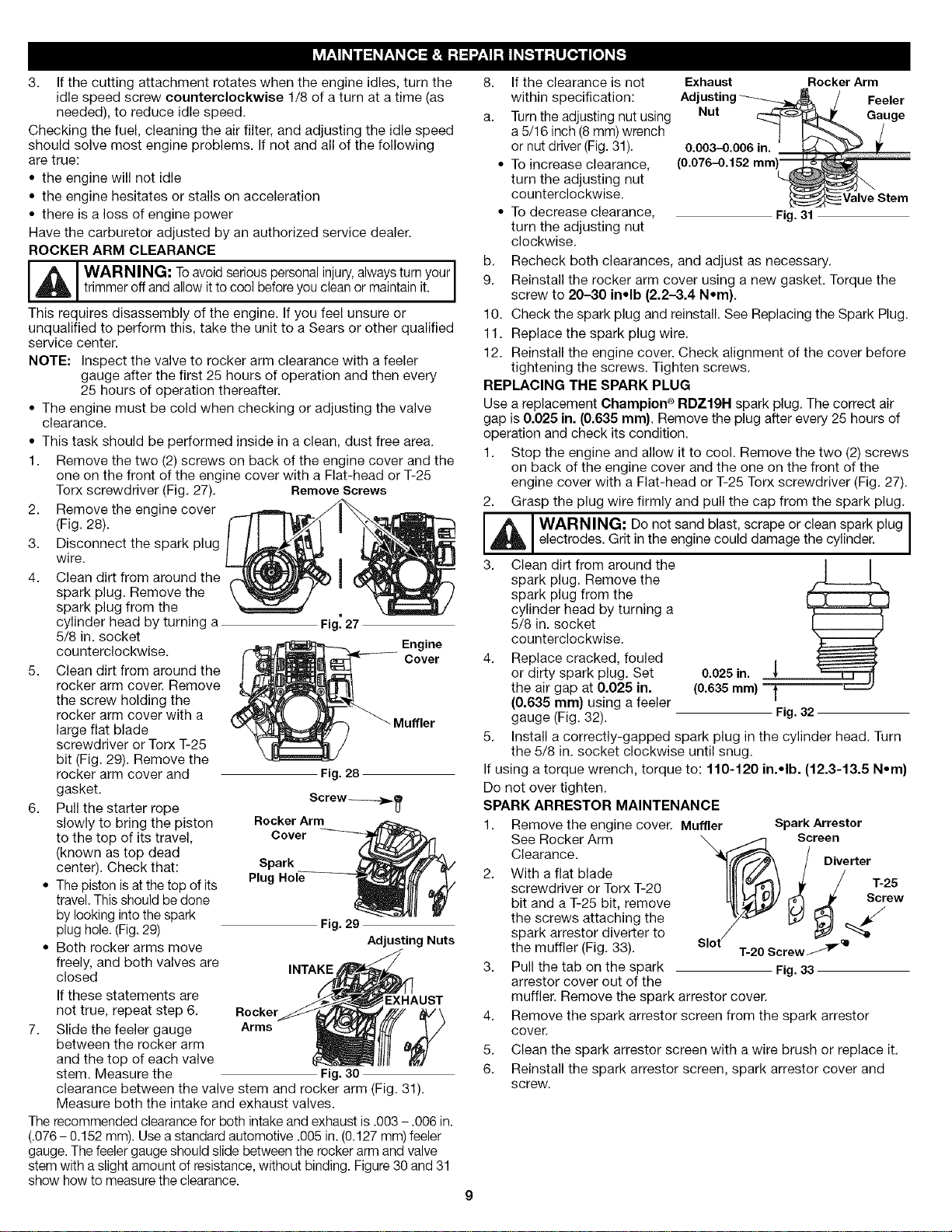

1. Remove the two (2) screws on back of the engine cover and the

one on the front of the engine cover with a Flat-head or T-25

Torx screwdriver (Fig. 27). Remove Screws

2. Remove the engine cover

(Fig. 28).

3. Disconnect the spark plug

wire.

4. Clean dirt from around the

spark plug. Remove the

spark plug from the

cylinder head by turning a Fig_27

5/8 in. socket

counterclockwise. Engine

Cover

5. Clean dirt from around the

rocker arm cover. Remove

the screw holding the

rocker arm cover with a

large flat blade

screwdriver or Torx T-25

bit (Fig. 29). Remove the

rocker arm cover and Fig. 28

gasket.

6. Pull the starter rope Screw_,_,

slowly to bring the piston Rocker Arm

to the top of its travel, Cover

(known as top dead

center). Check that: Spark

• The piston isat the top of its Plug

travel. This should be done

by looking into the spark

plug hole. (Fig.29) Fig. 29

Adjusting Nuts

• Both rocker arms move

freely, and both valves are

INTAKE

closed

If these statements are EXHAUST

not true, repeat step 6. Rocker t_V\

7. Slide the feeler gauge Arms

between the rocker arm

and the top of each valve

stem. Measure the Fig. 30

clearance between the valve stem and rocker arm (Fig. 31).

Measure both the intake and exhaust valves.

The recommended clearance for both intake and exhaust is .003 - .006 in.

(.076 - 0.152 ram). Use a standard automotive .005 in. (0.127 mm) feeler

gauge. The feeler gauge should slide between the rocker arm and valve

stem with a slight amount of resistance, without binding. Figure30 and 31

show how to measure the clearance.

8. If the clearance is not Exhaust Rocker Arm

within specification: Ad Feeler

a. Turn the adjusting nut using Nut Gauge

a 5/16 inch (8 ram) wrench

or nut driver (Fig. 31). 0.003-0.006 in.

• To increase clearance, (0.076-0.152 mm

turn the adjusting nut

counterclockwise.

• To decrease clearance, Fig.31

turn the adjusting nut

clockwise.

b. Recheck both clearances, and adjust as necessary.

9. Reinstall the rocker arm cover using a new gasket. Torque the

screw to 20-30 in•lb (2.2-3.4 N•m).

10. Check the spark plug and reinstall. See Replacing the Spark Plug.

11. Replace the spark plug wire.

12. Reinstall the engine cover. Check alignment of the cover before

tightening the screws. Tighten screws.

REPLACING THE SPARK PLUG

Use a replacement Champion ®RDZ19N spark plug. The correct air

gap is 0.025 in. (0.635 ram). Remove the plug after every 25 hours of

operation and check its condition.

1. Stop the engine and allow it to cool. Remove the two (2) screws

on back of the engine cover and the one on the front of the

engine cover with a Flat-head or T-25 Torx screwdriver (Fig. 27).

2. Grasp the plug wire firmly and pull the cap from the spark plug.

_ I WARNING: Do not sand blast, scrape or clean spark plug I

electrodes. Grit in the engine could damage the cylinder.

3. Clean dirt from around the J J

spark plug. Remove the

spark plug from the

cylinder head by turning a

5/8 in. socket

counterclockwise. ._

4. Replace cracked, fouled

or dirty spark plug. Set 0.025 in.

the air gap at 0.025 in. (0.635ram)

(0.635 mm) using a feeler

gauge (Fig. 32). Fig.32

5. Install a correctly-gapped spark plug in the cylinder head. Turn

the 5/8 in. socket clockwise until snug.

If using a torque wrench, torque to: 110-120 in.•lb. (12.3-13.5 N•m}

Do not over tighten.

SPARK ARRESTOR MAINTENANCE

1. Remove the engine cover. Muffler Spark Arrestor

See Rocker Arm

Clearance.

2. With a flat blade

screwdriver or Torx T-20

bit and a T-25 bit, remove

the screws attaching the

spark arrestor diverter to

the muffler (Fig. 33).

3. Pull the tab on the spark

arrestor cover out of the

Screen

Diverter

/ T-25

Sl°t_crew_ "+

Fig.33

muffler. Remove the spark arrestor cover.

4. Remove the spark arrestor screen from the spark arrestor

cover.

5. Clean the spark arrestor screen with a wire brush or replace it.

6. Reinstall the spark arrestor screen, spark arrestor cover and

screw.

Loading ...

Loading ...

Loading ...