Loading ...

Loading ...

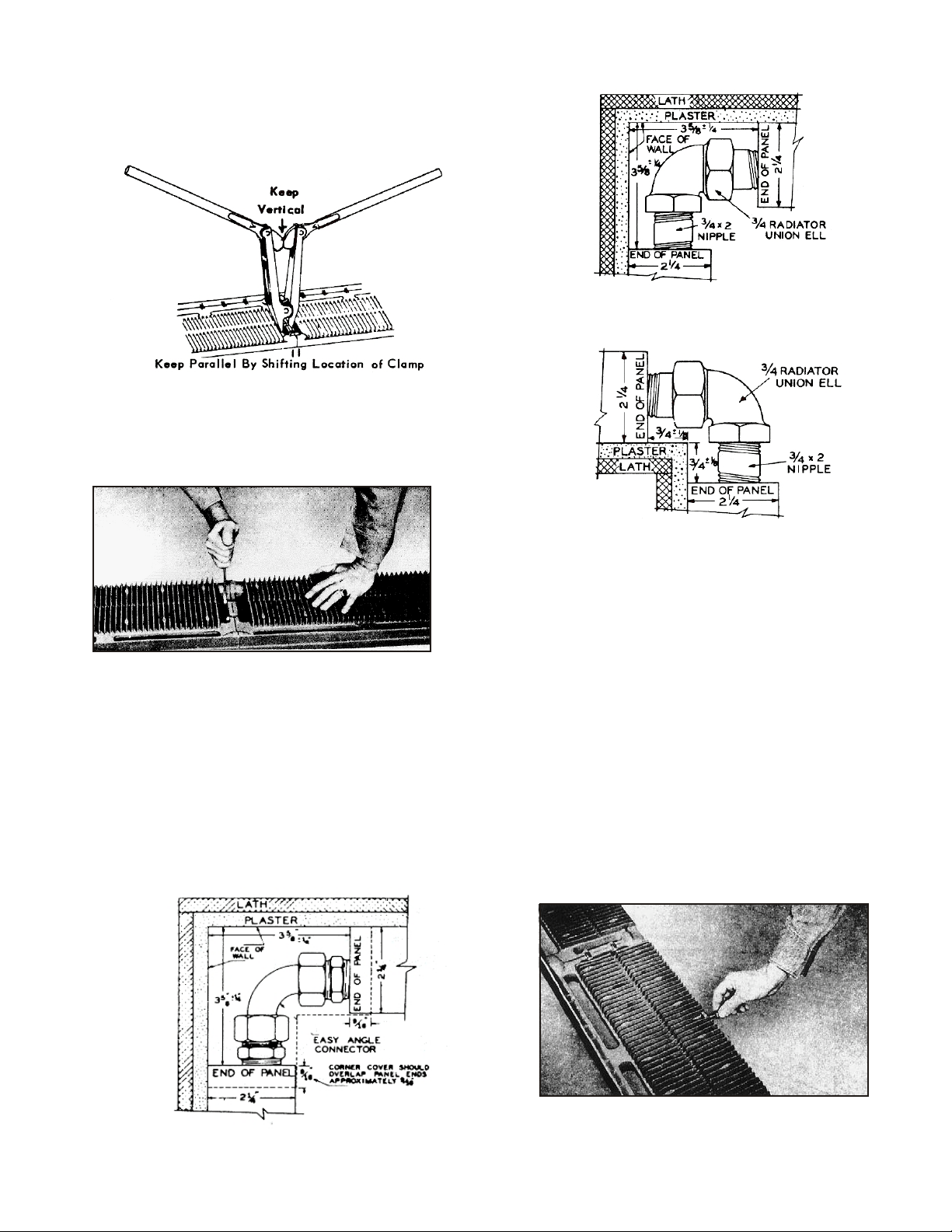

Note following precautions (Fig. 8):

a. Keep clamp vertical.

b. Keep ends of sections parallel.

c. Apply steady pressure.

When sections are drawn up, remove clamp and

place 5/16” tie bolts in place. Tighten with open-end

wrench for 5/16” hex nut (Fig. 9). Make sure

sections are assembled perfectly straight, are in

perfect alignment and are not bowed.

For corner connections using copper connections,

install and tighten adapter or compression fittings

(Fig. 10). For cast iron corner connections, install

and tighten straight piece of union radiator valves

and elbows (Fig. 11 & 12). Plug unused openings

with 3/4” plug (furnished). Check plug to make sure

connection is tight.

EASY ANGLE COPPER CONNECTION

INSTALLING CENTER LEG SUPPORTS

Screw 3/8” x 1-1/2” leg support screws furnished in

selected support lugs on bottom of intermediate

section (Fig. 13). Table below gives required

number of screws based on panel length. Space

support screws evenly.

Panel length No. of supports

6’ - 14’1

15’ - 21’2

22’ - 30’3

Stand panel in position against wall. The legs at the

end of the panels should rest on the finished floor or

wood elevating blocks or strips. Adjust support

screws to bear on floor and give equal distribution of

weight over entire panel length.

INSTALL AIR SEAL

Place air seal the length of the panel plus 1” overlap.

The seal should be installed securely and smoothly

in place with tacks (Fig. 4 & 5). If baseboard is to be

set before finished floor is in place, air seal should

extend to rough floor. Mark location of the studs on

the front of the air seal. These marks will be used to

position the holding clips after the panel is in

position. It is recommended that a wood molding be

used at the finished floor line to hold the air seal

snugly to the wall.

CAST IRON BASEBOARD PANEL ASSEMBLY

Be sure to remove protective plugs from

nipple ports and tappings before assembling panel.

1. Line up two sections on the floor with fins up

(Fig. 6).

Tacking paper seal in place

Fig. 5

Cross-section of end elevation

2. Remove protective plugs from the nipple

ports and tappings.

3. Clean the edges and push nipple ports on

the sections.

4. Wipe push nipples clean.

5. Apply thin coating of graphite paste or pipe

joint compound to the external surfaces of

the nipples.

6. Insert push nipples into one section, square

them, and tap them firmly into place with a

rawhide or wooden mallet.

7. Fit the second panel to the nipples.

8. Place the jaws of the clamp in the two

recesses between the push nipple hubs

and pull together (Fig. 7).

Fig. 6

Fig. 7

Fig. 8

Fig. 12

Fig. 11

Fig. 10

Tightening 5/16” hex nuts on tie bolts

after sections have been drawn up

Plan view of inside corner hookup

Plan view of outside corner hookup

Screw center leg support in baseboard

CAST IRON CONNECTIONS

Fig. 13

Fig. 9

Fig. 4

Part No. 550-110-455 0707

2

3

Part No. 550-110-455 0707

CAUTION

Loading ...

Loading ...

Loading ...