Loading ...

Loading ...

Loading ...

IM-40MHH-02 Specifications subject to change without notice. 13

Install All Power, Interconnecting Wiring, and

Piping to the Indoor Unit

1. Run the interconnecting piping and wiring from the outdoor unit to

indoor unit.

2. Run the interconnecting cable through hole in wall (outside to

inside).

3. Lift the indoor unit into position and route piping and drain through

the hole in wall (inside to outside). Fit the interconnecting wiring

into back side of indoor unit.

4. Put the upper claw at back of indoor unit on upper hook of

Mounting Plate, move indoor unit from side to side to see that it is

securely hooked.

5. Open the indoor unit’s front panel by loosening the screws, which

provides a large space for wiring connection.

6. Open the wire box cover to connect the cable.

7. Pull the interconnecting wire up from back of indoor unit and

position in close to the terminal block on indoor unit.

8. Push the lower part of indoor unit up on wall, then move indoor unit

from side to side, up and down to check if it is hooked securely (see

Fig. 22).

Fig. 22 — Indoor Unit Installation

9. Connect wiring from outdoor unit per connection diagram (see Fig.

18 and Fig. 19).

10. Replace the wire cover on the front of the unit, and the plastic panel

on the back.

Piping

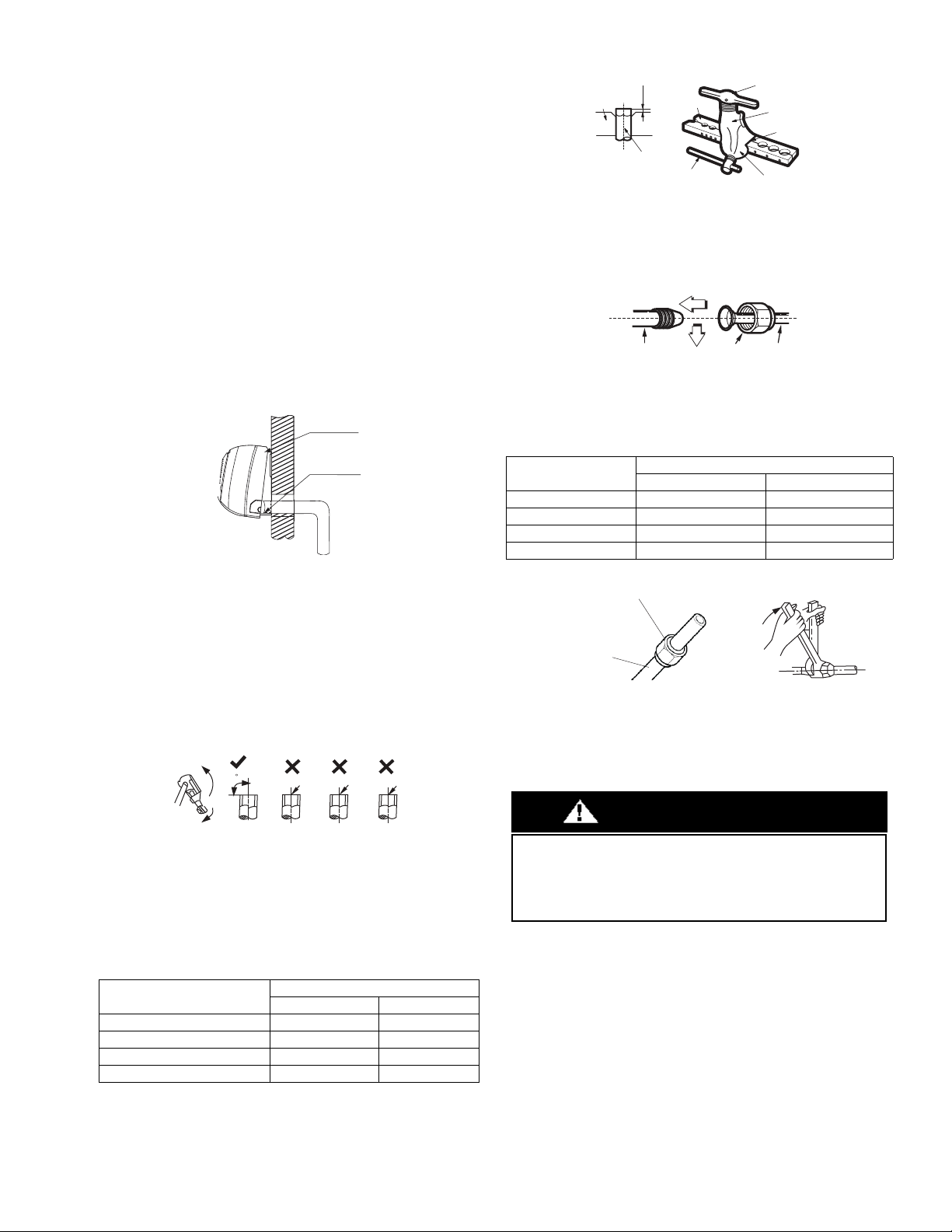

a. Cut the pipe, with a pipe cutter, at 90 degrees (see Fig. 23).

b. Remove the service connection, if provided with the unit.

Fig. 23 — Pipe Cutting

c. Remove all the burrs from the cut cross section of the pipe

avoiding any burrs inside the tubes.

d. Remove the flare nuts attached to the indoor and outdoor

units.

e. Install the correct size flare nut onto the tubing and make the

flare connection. Refer to Table 6 for the flare nut spaces.

Table 6 — Flare Nut Spacing

Fig. 24 — Flare Nut Spacing

f. Apply a small amount of refrigerant oil to the flare

connection on the tubing.

g. Align center of the pipes and/or service valve.

Fig. 25 — Align Pipe Center

h. Connect both the liquid and gas piping to the indoor unit

i. Tighten the flare nut using a torque wrench as specified in

Table 7.

Table 7 — Tightening Torque

Fig. 26 — Tighten the flare nut

For additional diagnostic information, refer to the Service Manual.

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate

triple evacuation method may be used if the procedure outlined below

is followed. Always break a vacuum with dry nitrogen.

OUTER DIAM INCH (MM)

A INCH (MM)

MAX. MIN.

Ø 1/4” (6.35) 0.05 (1.3) 0.03 (0.7)

Ø 3/8” (9.52) 0.06 (1.6) 0.04 (1.0)

Ø 1/2” (12.7) 0.07 (1.8) 0.04 (1.0)

Ø 5/8” (15.88) 0.09 (2.2) 0.08 (2.0)

Upper hook

Lower hoo

k

Oblique

90

Roughness

Burr

PIPE DIAMETER

INCH (MM)

TIGHTENING TORQUE

Ft-lb N - m

Ø1/4” (6.35) 10 to 13 13.6 to 17.6

Ø3/8” (9.52) 24 to 31 32.5 to 42.0

Ø1/2” (12.7) 37 to 46 50.1 to 62.3

Ø5/8” (15.88) 50 to 60 67.7 to 81.3

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Indoor unit tubing Flare nut Piping

Flare nut

Coppe

r tube

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Never use the system compressor as a vacuum pump.

CAUTION

Loading ...

Loading ...

Loading ...