Loading ...

Loading ...

Loading ...

3. Remove the fan housing.

4. Use a 9/16" socket wrench on the flywheel

nut to keep the crankshaft from moving.

Figure 49.

NOTE: Place the socket handle forward as

shown in Figure49.

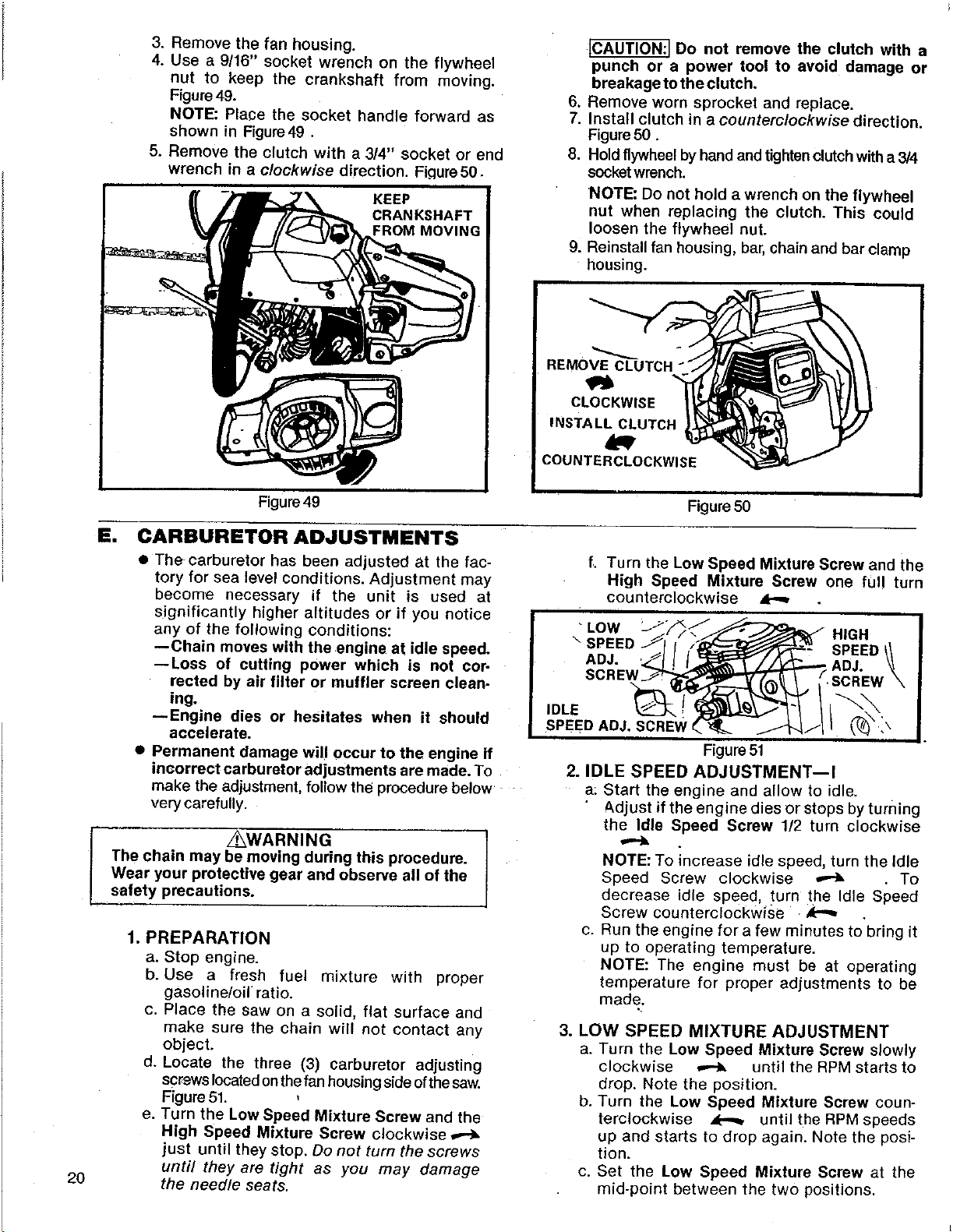

5. Remove the clutch with a 3/4" socket or end

wrench in a clockwise direction. Fiqure50.

[CAUTION:_ Do not remove the clutch with a

punch or a power tool to avoid damage or

breakage to the clutch.

6. Remove worn sprocket and replace.

7. Install clutch in a counterclockwise direction.

Figure50.

8. Hold flywheelbyhand and tightenclutchwitha 3/4

socketwrench.

NOTE: Do not hold a wrench on the flywheel

nut when replacing the clutch. This could

loosen the flywheel nut•

9. Reinstall fan housing, bar,chain and bar clamp

housing.

REMOVE CLUTCH

CLOCKWISE

INSTALL CLUTCH

COUNTERCLOCKWISE

2O

Em

Figure49

Figure 50

CARBURETOR ADJUSTMENTS

• The-carburetor has been adjusted at the fac-

tory for sea level conditions. Adjustment may

become necessary if the unit is used at

significantly higher altitudes or if you notice

any of the following conditions:

--Chain moves with the engine at idle speed.

--Loss of cutting power which is not cor-

rected by air filter or muffler screen clean-

ing.

--Engine dies or hesitates when it should

accelerate•

• Permanent damage will occur to the engine if

incorrect carburetor adjustments are made. To

make the adjustment, follow the procedure below

very carefully.

I _WARNING

The chain may be moving during this procedure.

Wear your protective gear and observe all of the

. safety precautions.

1. PREPARATION

a. Stop engine.

b. Use a fresh fuel mixture with proper

gasoline/oil ratio.

c. Place the saw on a solid, flat surface and

make sure the chain will not contact any

object.

d. Locate the three (3) carburetor adjusting

screwsIocatedonthe fan housing side of thesaw.

Figure 51.

e. Turn the Low Speed Mixture Screw and the

High Speed Mixture Screw clockwise

just until they stop. Do not turn the screws

until they are tight as you may damage

the needle seats.

f. Turn the Low Speed Mixture Screw and the

High Speed Mixture Screw one ful! turn

counterclockwise a--,,

IDLE

SPEED ADJ. SCREW

•LOW HIGH

SPEED

ADJ. : ADJ;

SCREW

Figure 51

2. IDLE SPEED ADJUSTMENT--I

a: Start the engine and allow to idle.

Adjust if the engine dies or stops by turning

the Idle Speed Screw 1/2 turn clockwise

NOTE: To increase idle speed, turn the Idle

Speed Screw clockwise _ . To

decrease idle speed, turn the Idle Speed

Screw counterclockwise

c. Run the engine for a few minutes to bring it

up to operating temperature.

NOTE: The engine must be at operating

temperature for proper adjustments to be

made.

3. LOW SPEED MIXTURE ADJUSTMENT

a. Turn the Low Speed Mixture Screw slowly

clockwise _ until the RPM starts to

drop. Note the position.

b. Turn the Low Speed Mixture Screw coun-

terclockwise _ until the RPM speeds

up and starts to drop again. Note the posi-

tion.

c. Set the Low Speed Mixture Screw at the

mid-point between the two positions.

Loading ...

Loading ...

Loading ...