Loading ...

Loading ...

Loading ...

CUS rOMER RESPONSIBILITIES ..........

11 iiiiiiiiiii ii ii iiiiiiiiiii

SNOW THROWER

LUBRICATION - EVERY FIVE HOURS

• Lubricate the flange on tile discharge chute every

five (5) hours during use and before storage (See

Fig_ 17)_

® See Lubrication Chart diagram on page 15 for

lubrication points and type of lubricant..

LUBRICATION - EVERY TEN HOURS

® Auger Shaft-. For storage, lubricate auger shaft ( See

Fig. 16) with a clinging type grease such as Lubdplate.

When replacing shear bolts, remove shear bolts and

lubricate auger shaft (see To Reptace Shear Bolt

paragraph on page 23).

@ The chute control rod, used to change the direction

of the snow discharge, needs to be lubricated

frequently and before storage (See Fig.. 17).

® See Lubrication Chart diagram on page 15 fo_"

iubdcation points and type of lubricant.

LUBRICATION - EVERY 25 HOURS

® Position speed selector lever infirst gear,

® Place a coin or (a shim of equal thickness) between

the rubber friction wheel and disc drive plate to

prevent friction wheel contacting the friction disc

@ DiscDrive Plate - Using a hand grease gun, lubricate

witha Hi Temp EP Motygrease, zerk locatedbeneath

the disc drive plate (See Fig, 18 inset) every 25 hours

and at the end of the season andlor before storage

To grease zerk, turn disc drive plate clockwise by

hand untilzerk is clearly visibleat front center DO

NOT overfil! or allow grease to come in wheel or

damage will resulL Fitlzerk only untilgrease becomes

visible below bearing assembly located undergrease

zerk See Lubrication Chart on page 15

® IMPORTANT; Remove coin and ensure that a gap

exists between friction wheel and disc drive

plate.

@ NOTE: Clean al! excess grease found on friction

disc hub..

• CAUTION: Do not allow grease to contact friction

wheel and disc drive plate,,

LUBRICATION - BEFORE STORAGE

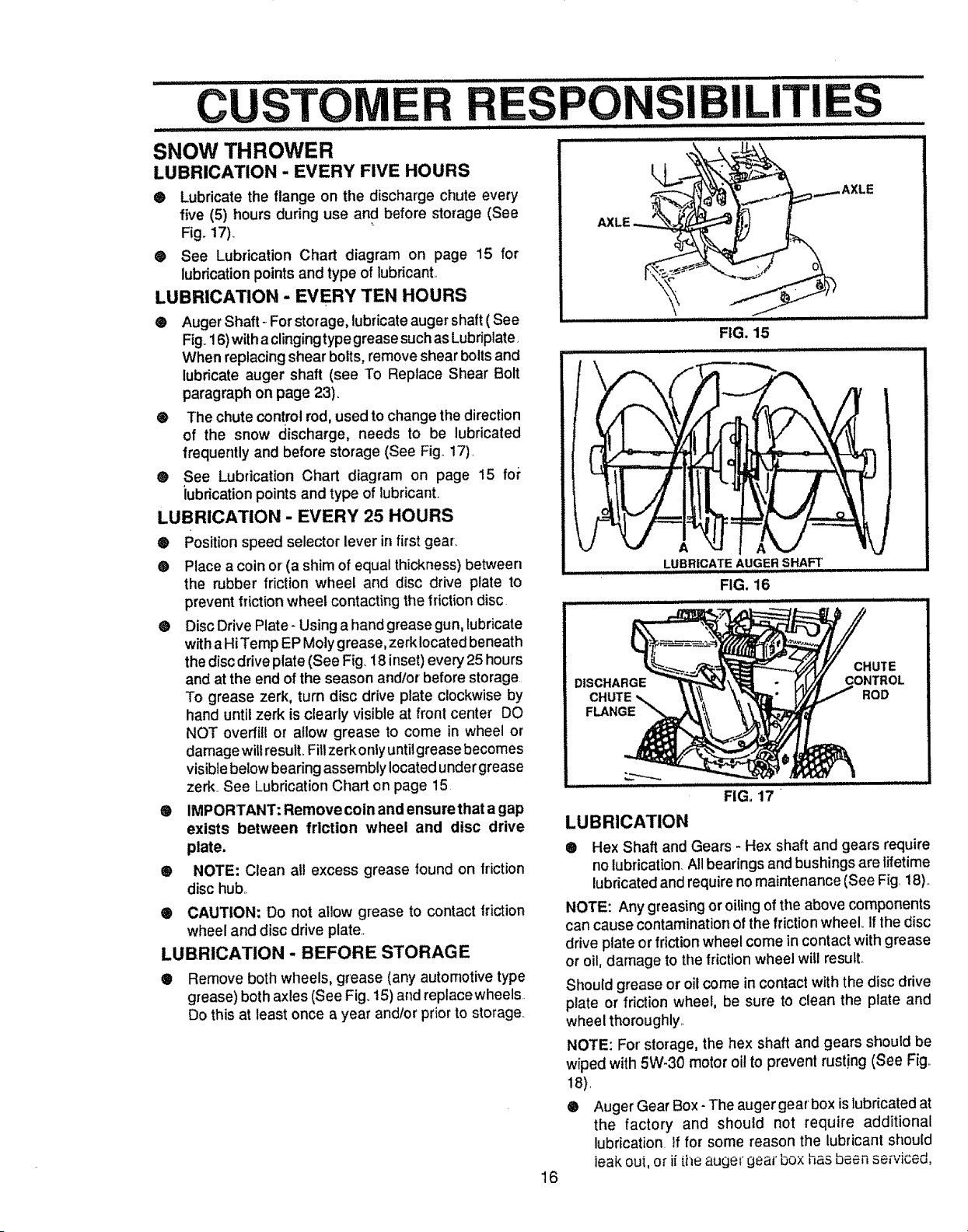

® Remove both wheels, grease (any automotive type

grease) both axles (See Fig. 15) and replacewheels

Do this at least once a year andtor prior to storage

.................... .......................

__ _......AXLE

I II I/1/111111111111111

FIG. 15

LUBRICATE AUGER SHAFt'

FIG. 16

\

DISCHARGE

FLANGE

CHUTE

CONTROL

ROD

16

FiG, 17

LUBRICATION

® Hex Shaft and Gears - Hex shaft and gears require

no lubrication All bearings and bushings are lifetime

lubricated and require no maintenance (See Fig. 18)..

NOTE: Any greasing or oiling of the above components

can cause contamination of the friction wheel. If the disc

drive plate or friction wheel come in contact with grease

or oil, damage to the friction wheel will result.

Stlould grease or oil come in contact with the disc drive

plate or friction wheel, be sure to clean the plate and

wheel thoroughly,.

NOTE: For' storage, the hex shaft and gears should be

wiped with 5W-30 motor oil to prevent rusting (See Fig..

18).

® Auger Gear Box - The auger gearbox is lubricatedat

the factory and should not require additional

lubrication_ If for some reason the lubricant should

leak out, or ii ihe auger geaJ"box has been se[viced,

Loading ...

Loading ...

Loading ...