Loading ...

Loading ...

UK/2

1 TECHNICAL DATA

1.1 DESCRIPTION OF THE OVEN

The oven comprises several units positioned one on top of the other:

- hood

- baking chamber/s

- base

- lower frame (stand) or proofer

Each baking chamber is totally independent and is equipped with

electronic temperature regulator, safety thermostat and with a single

door hinged at the bottom.

According to the model, the internal structure of the chamber can be

made entirely of metal plate, with a refractory brick or an embossed

metal baking surface.

The support element comprises a steel structure fitted with tray holder

guides.

The proofer comprises a steel structure which is panelled, has tray

holder guides and is fitted with a thermostat for heating.

1.2 REGULATIONS APPLIED

UL STD 197

NSF STD 4

CAN/CSA C22.2 STD No.109

1.3 WORKPLACES

The appliances are programmed by the operator using the control

switchboards on the front of the appliances themselves, and they must

be attended to while in operation.

The doors giving access to the appliances are located at the front

1.4 MODELS

The following models are available:

AMALFI C (indicated in the certification as AMAC)

P120E C (indicated in the certification as P12C)

AMALFI L (indicated in the certification as AMAL)

P120E L (indicated in the certification as P12L)

1.5 WORKING DIMENSIONS AND WEIGHTS (See tab.)

1.6 TECHNICAL DATA (See tab.)

1.7 IDENTIFICATION

When communicating with the manufacturer or service centre, always

give the appliance SERIAL NUMBER, which can be found on the

rating plate, fixed in the position indicated in figure 1.

1.8 LABELLING

The appliance is provided with safety warning labels at the points

indicated in figure 1 end 2:

A - Large sign "HOT SURFACE"

B - Sign "PROOFER SANITATION"

C - Sign "FITTING FUSES"

D - Sign "CONNECTION 9 AWG" or "CONNECTION 7 AWG"

or "CONNECTION 5 AWG"

E - Sign "PREVENTION OF FIRE AND ELECTRIC SHOCKS"

F - Label "ELECTRIC U.S. AND CANADA AND SANITATION"

G - Sign "ELECTRIC SHOCK"

H - Sign "PHASE IDENTIFICATION"

I - Small sign "HOT SURFACE"

L - Sign "DISTANCE FROM WALL"

M - Sign "LAMP"

2 INSTALLATION

2.1 TRANSPORT

The appliance is normally delivered dismantled on wooden pallets

using overland transport (fig. 3).

The single parts are protected by plastic film or in cardboard boxes.

2.2 UNLOADING

NOTE: On receiving the appliance it is advisable to check its

conditions and quality.

Raise the equipment using only and exclusively the points indicated at

the pict. 4.

2.3 ENVIRONMENTAL SPECIFICATIONS

To ensure that the oven operates properly, it is advisable to comply

with the following limits:

Working temperature: +5°C÷+40°C

Relative humidity: 15%÷95%

2.4 POSITIONING, ASSEMBLING AND MAINTENANCE

AREAS

WARNING! When positioning, assembling and installing the oven,

the following specifications have to be complied with:

- Laws and standards in force regarding the installation of

electrical appliances.

- Directives and indications issued by the electricity supply

network.

- Local building and fire-prevention laws

- Accident prevention regulations.

- Regulations in force of the electromechanical rules.

- The appliances must be installed in conformity with current

national regulations.

Remove the protective film from the outside of the oven, pulling it

gently to remove all the adhesive.

Should any adhesive remain on the oven, remove using kerosene or

benzene.

The single elements that have been selected to make up the oven must

be placed one on top of the other as shown in figure 5, slotting the

reference feet of each unit into the housing on the one underneath it

(item A - fig.5).

The equipment needs to be placed in a well ventilated area.

The following minimum gaps must be left between the oven and any

combustible or non-combustible construction (see fig. 6):

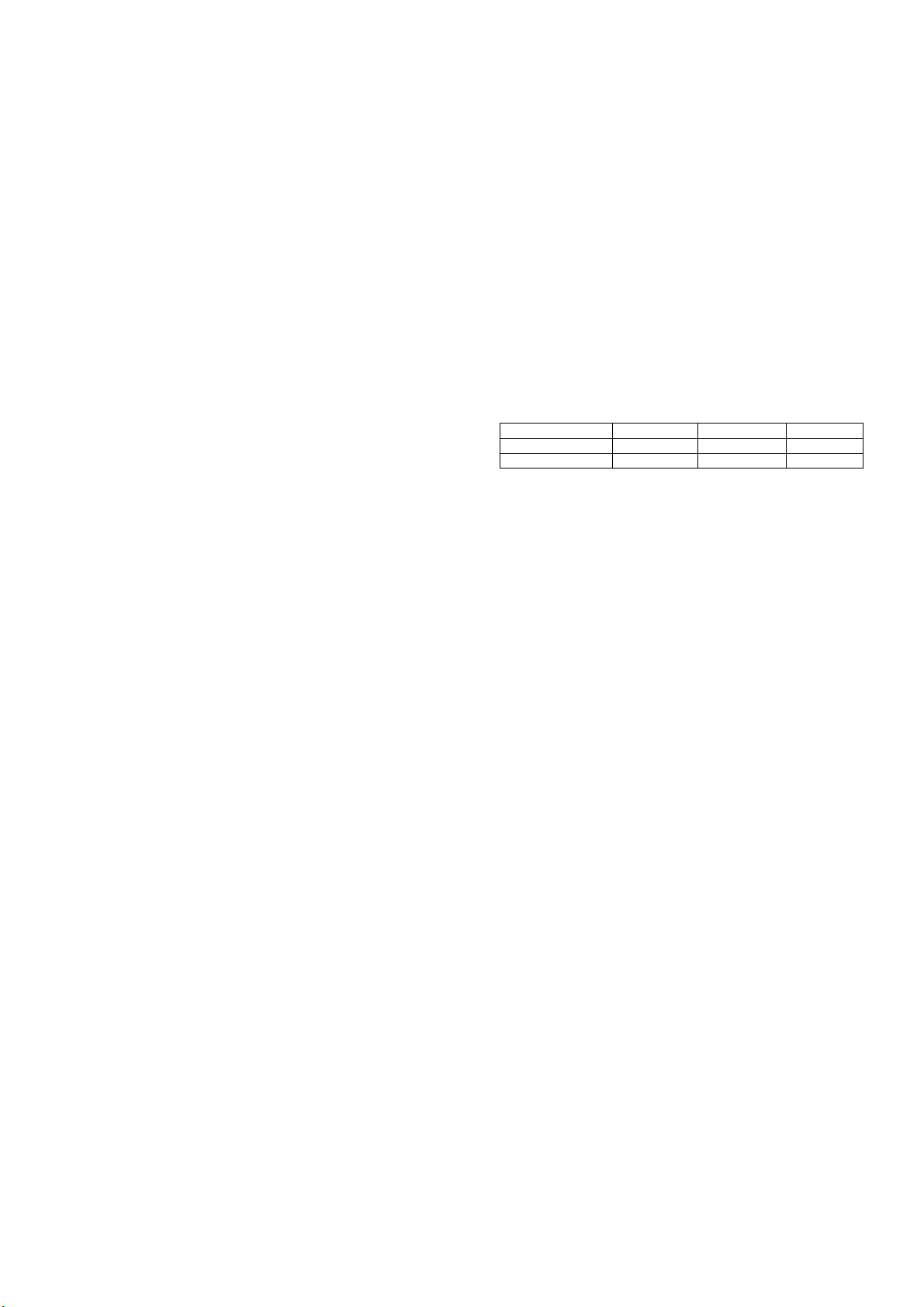

N. Chambers

A

B

C

1-2-3

4” (10cm)

4” (10cm)

1” (2,5cm)

Servicing

20” (50cm)

20” (50cm)

20” (50cm)

Take into account that for certain cleaning/maintenance operations, the

distance needs to be greater than stated here and therefore, consider the

possibility to be able to move the oven for the purpose of carrying out

these operations.

WARNING! After final assembly of the oven, a bead of NSF

approved silicone must be run around all the joints to avoid liquids

or dirt entering.

2.5 CONNECTIONS

2.5.1 VAPOUR EXHAUST CONNECTION

WARNING! Connection of the vapour exhaust must only be

carried out by specialised personnel.

The vapour exhaust pipe is located at the rear of the oven (fig. 7 item

C). Insert the perforated ring (fig. 7 item B) in the vapour exhaust

outlet and connect.

NOTE: It is recommended that you connect the vapour exhaust to

a flue or to the outside using a pipe with a minimum diameter of

110 mm.

This pipe (fig. 7 item A) must be inserted into the oven exhaust outlet

by means of the ring. Any extensions must also be connected so that

the upper pipes fit into the lower ones, as illustrated for the connection

described above.

If the external vapour exhaust pipe is very long, it is advisable to fit a

small plastic tube at the base of the pipe itself to drain off any

condensation (fig.7 item D). This operation must be carried out before

coupling the pipe to the outlet.

WARNING! Openings in food zones shall be protected to prevent

the entry of seepage, condensation, and spills. Covers protecting a

food shall overlap the opening and shall be sloped to provide

drainage from the cover surface.

2.5.2 ELECTRICAL CONNECTION

WARNING! Electrical connection must only be carried out by

specialised personnel, in compliance with current local state

Electric Quality Assurance Corporation requirements. In the

absence of local codes, Electrical connection must conform with the

National Electrical Code (NEC) ANSI/NFPA70 and Canadian

Electrical Code CSA C22.2.

- Before starting the connection procedure, check that the

earthing system is provided in accordance with local codes.

- Before starting the connection procedure, check that the main

power switch has been turned to the “off” position.

- The rating plate contains all the information necessary for

proper connection.

2.5.2.1 ELECTRICAL CONNECTION OF THE BAKING

CHAMBER

WARNING! Each of the baking chambers must be fitted with a

omnipolar main switch with fuses or an automatic switch suitable

for the values shown on the plate, to allow the single appliances to

be disconnected from the mains.

Loading ...

Loading ...

Loading ...