Loading ...

Loading ...

Loading ...

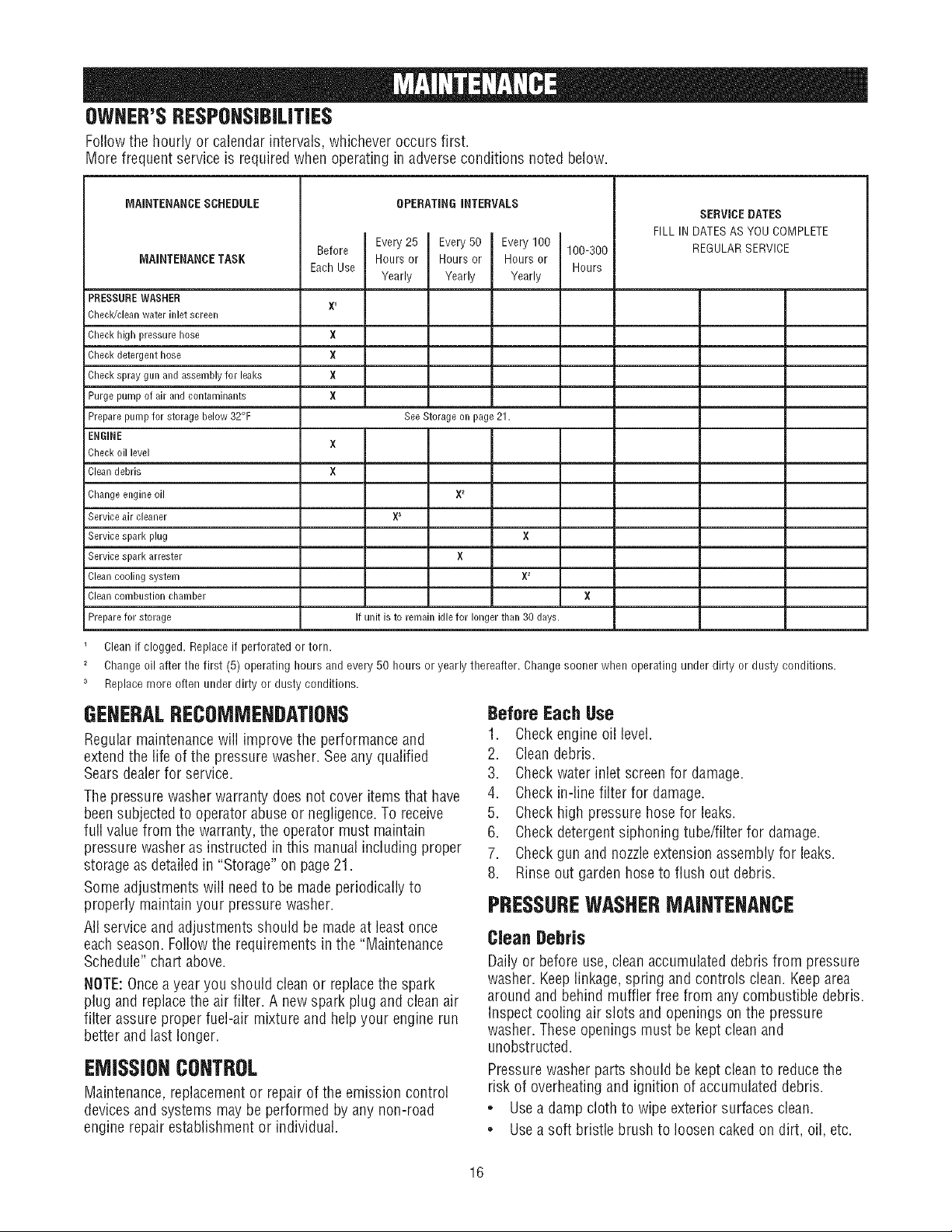

OWNER'SRESPONSIBILITIES

Followthe hourly or calendar intervals,whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

MAINTENANCESCHEDULE

MAINTENANCETASK

PRESSUREWASHER

ChecWclean water inlet screen

Cheek high pressure bose

Check detergent hose

Check spray gun and assembly for leaks

Purge pump of air and contaminants

Prepare pump for storage below 32°F

ENGINE

Before

Each Use

X1

X

X

X

X

OPERATINGiNTERVALS

I

Every 25

Hours or

Yearly

Every 50

Hours or

Yearly

I very 100

Hours or

Yearly

See Storage on page 21.

100-300

Hours

SERVICEDATES

FILL IN DATESAS YOU COMPLETE

REGULARSERVICE

Check oil level

Clean debris

Change engine oil

Service air cleaner

Service spark plug

Service spark attester

Clean cooling system

Clean combustion chamber

Preparefor storage

X

X

X2

X_

X

X

X_

If unit is to remain idle for longer than 30 days.

Cleanif clogged. Replace if perforated or torn.

2 Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Changesooner when operating under dirty or dusty conditions.

3 Replace more often under dirty or dusty conditions.

GENERALRECOMMENDATIONS

Regular maintenancewill improve the performance and

extendthe life of the pressure washer. See any qualified

Sears dealerfor service.

The pressurewasher warranty does not cover items that have

beensubjected to operator abuse or negligence.To receive

full value from the warranty, the operator must maintain

pressure washeras instructed in this manualincluding proper

storage as detailed in "Storage" on page21.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least once

each season. Follow the requirements in the "Maintenance

Schedule" chart above.

NOTE:Oncea year you should clean or replace the spark

plug and replace the air filter. A new spark plug and clean air

filter assure proper fuel-air mixture and help your engine run

better and last longer.

EMiSSiON CONTROL

Maintenance, replacementor repair of the emission control

devices and systems may be performed by any non-road

engine repair establishment or individual.

Before Each Use

1. Check engine oil level.

2. Clean debris.

3. Check water inlet screenfor damage.

4. Check in-line filter for damage.

5. Check high pressure hose for leaks.

6. Check detergent siphoning tube/filter for damage.

7. Check gun and nozzleextension assembly for leaks.

8. Rinseout garden hose to flush out debris.

PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use, clean accumulated debris from pressure

washer. Keeplinkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Inspect cooling air slots and openings on the pressure

washer. Theseopenings must be kept clean and

unobstructed.

Pressurewasher parts should be kept clean to reduce the

risk of overheatingand ignition of accumulated debris.

• Usea damp cloth to wipe exterior surfaces clean.

• Usea soft bristle brush to loosen caked on dirt, oil, etc.

16

Loading ...

Loading ...

Loading ...