Loading ...

Loading ...

Loading ...

12 www.dimplex.com

FLICKER ROD REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

Short handled Phillips head screwdriver

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the inte-

rior Partially Reective Glass. A medium sized con-

tainer such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 13)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. In the bottom right hand of the unit, remove the two

screws and the front access cover. (Figure 11)

5. In the media tray, remove the two screws on either end

and the one on the side wall, to remove the clear media

tray and the front panel. (Figure 12)

!

NOTE: Tip the front panel forward then lift out of the unit.

6. Remove the icker rod by holding the gasket and slid-

ing it to the left. This will disengage it from the motor.

It will then be possible to remove it out of the opening.

7. Reassemble in the reverse order as above.

CAUTION: When removing and replacing the icker

motor try to keep any slight bending of the icker rod

minimal so as to not damage it. If icker rod is damaged, it

should be replaced to ensure proper operation.

CAUTION: When re-installing, be sure the wires are

guided and tucked into the proper openings along the right

side so they are not pinched and allows enough space to

reinstall the panels.

LED LIGHT STRIPS REPLACEMENT

WARNING: Disconnect power before attempting any

maintenance or cleaning to reduce the risk of electric

shock or damage to persons.

CAUTION: If unit was operating prior to servicing allow

at least 10 minutes for lights and heating elements to cool

off to avoid accidental burning of skin.

Tools required: Phillips head screwdriver

Wire Snips

CAUTION: Follow “Preparation for Service” instructions

before proceeding.

1. Remove the decorative acrylic ember-bed pieces from

the media tray, which lies along the bottom of the inte-

rior Partially Reective Glass. A medium sized con-

tainer such as a bucket or a box will be needed to keep

the acrylic ember-bed pieces together.

2. Remove the Partially Reective Glass retaining brack-

ets by removing the 3 screws on each brackets; (3

brackets in total), located on the left and right side of

the Partially Reective Glass. (Figure 13)

3. Remove the Partially Reective Glass. Carefully place

the glass assembly aside in a safe location.

4. In the bottom right hand of the unit, remove the two

screws and the front access cover. (Figure 11)

5. In the media tray, remove the two screws on either end

and the one on the side wall, to remove the clear media

tray and the front panel. (Figure 12)

6. Remove the icker rod. This can be done by sliding it

to the left which will disengage it from the icker motor.

7. Locate the LED strip that needs to be replaced.

8. Disconnect the wire from the board by pulling gently on

the connector at the end.

9. Remove the board from the mounting bracket by press-

ing in the center of the standoffs to release them.

10. Line up the holes on the board and gently press the

new board onto the mounts. Make sure the board is

secure.

11. Reconnect the wire.

12. Reassemble in the reverse order as above.

CAUTION: When removing and replacing the icker

motor try to keep any slight bending of the icker rod

minimal so as to not damage it. If icker rod is damaged, it

should be replaced to ensure proper operation.

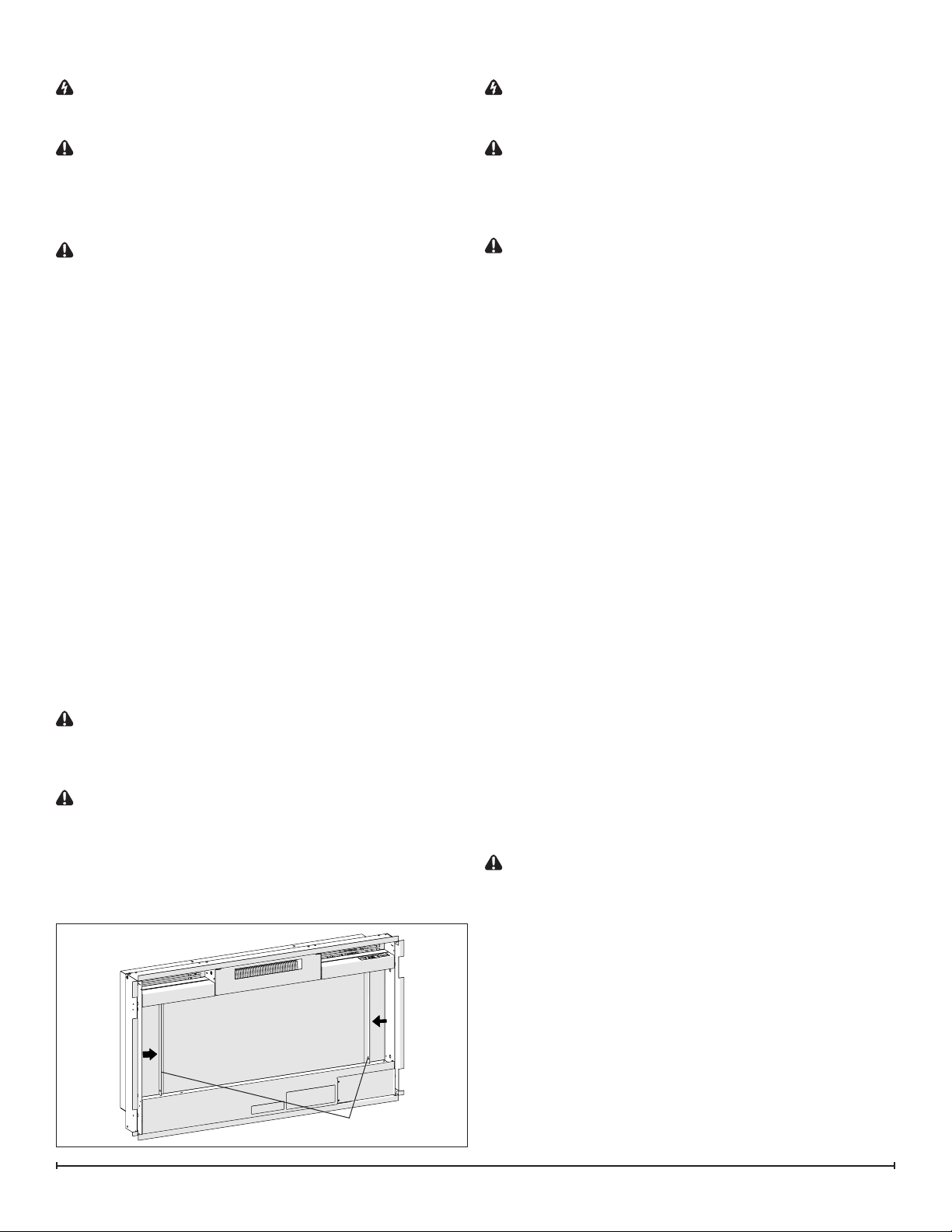

Figure 13

Retaining Brackets

Loading ...

Loading ...

Loading ...