Loading ...

Loading ...

Loading ...

SERVICE AND ADJUSTMENTS

Now proceed to the "Chain Adjustment" section.

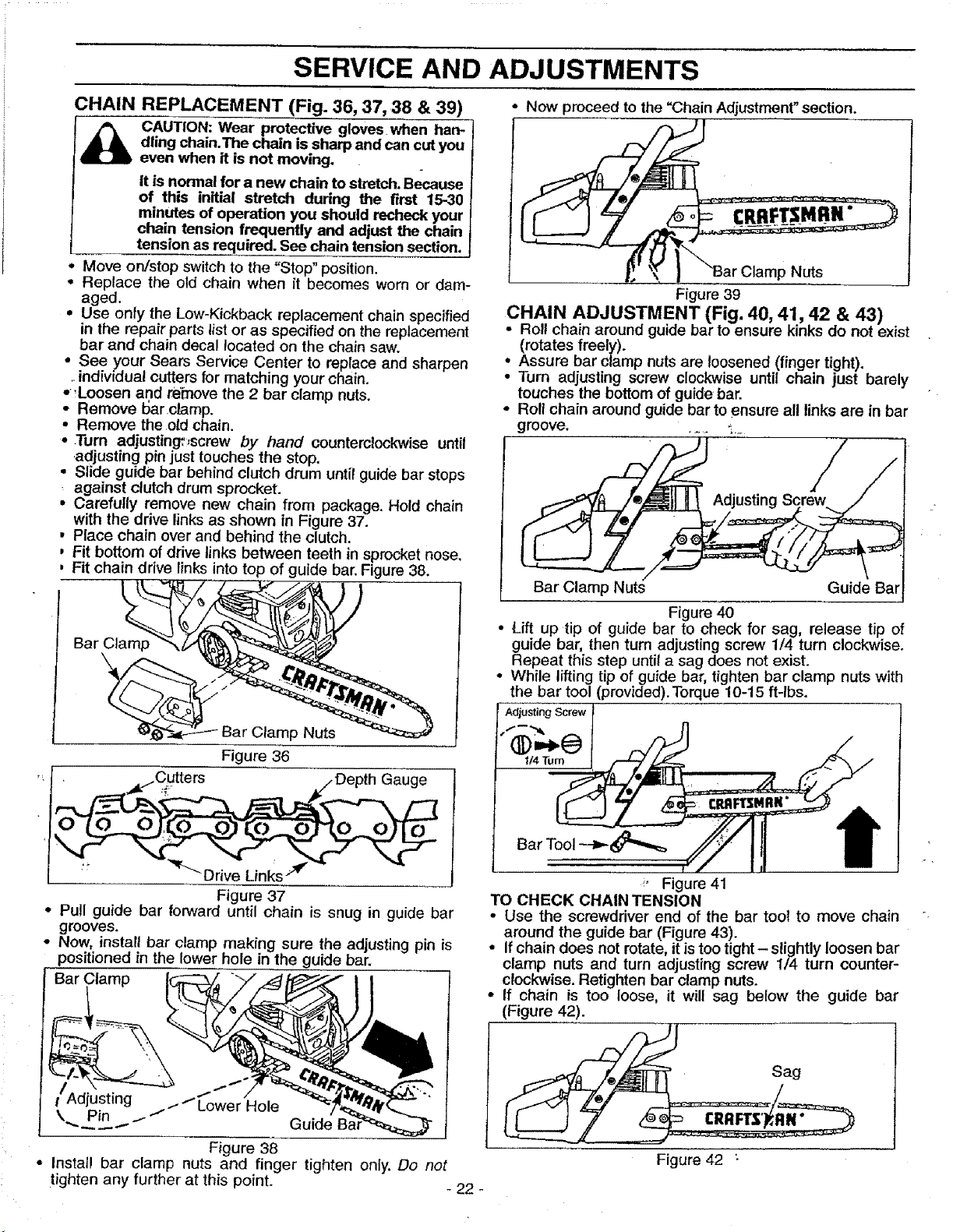

CHAIN REPLACEMENT (Fig. 36, 37, 38 & 39)

_ CAUTION: Wear protective gloves when han-

dling chain.The chain is sharp and can cut you

even when it is not moving.

it is normal for a new chain to stretch. Because

of this initial stretch during the first 15-30 i

minutes of operation you should recheck your

chain tension frequently and adjust the chain

tension as required. See chain tension section.

Move on/stop switch to the "Stop" position.

• Replace the old chain when it becomes worn or dam-

aged.

• Use on!y the Low-Kickback replacement chain specified

in the repair parts list or as specified on the replacement

bar and chain decal located on the chain saw.

• See your Sears Service Center to replace and sharpen

..individual cutters for matching your chain.

•,Loosen and re"move the 2 bar clamp nuts.

• Remove I:Jarclamp.

• Remove the old chain.

• .Turn adjusting_,screw by hand counterclockwise until

.adjusting pin just touches the stop.

• Slide guide bar behind clutch drum until guide bar stops

, against clutch drum sprocket.

• Carefully remove new chain from package. Hold chain

with the drive links as shown in Figure 37.

,Piace chain over and behind the clutch.

, Fit bottom of drive links between teeth in sprocket nose.

, Fit chain drive links into top of guide bar. Figure 38.

Bar Clamp

\

Clamp Nuts

Figure 36

• _/Cutte rs _/Depth Gauge

Figure 37

• Pull guide bar forward until chain is snug in guide bar

grooves.

• Now, install bar clamp making sure the adjusting pin is

positioned in the lower hole in the guide bar.

Bar Clamp

Adjusting .--"_

tt Lower Hole

\ Pin .i Guide

Figure 38

• install bar clamp nuts and finger tighten only. Do not

tighten any further at this poinL - 22 -

Nuts

Figure 39

CHAIN ADJUSTMENT (Fig. 40, 41, 42 & 43)

Roll chain around guide bar to ensure kinks do not exist

(rotates freely).

• Assure bar clamp nuts are loosened (finger tight).

• Turn adjusting screw clockwise until chain just barely

touches the bottom of guide bar.

• Roll chain around guide bar to ensure all links are in bar

groove ...... -,_

Bar Clamp Nuts Guide Bar

Figure 40

• Lift up tip of guide bar to check for sag, release tip of

guide bar, then turn adjusting screw 1/4 turn clockwise.

Repeat this step until a sag does not exist.

• While lifting tip of guide bar, tighten bar clamp nuts with

the bar tool (provided). Torque 10-15 ft-lbs.

Adjusting Screw

U4Tum

_, Figure 41

TO CHECK CHAIN TENSION

• Use the screwdriver end of the bar tool to move chain

around the guide bar (Figure 43).

• Ifchain does not rotate, it istoo tight- slightly loosen bar

clamp nuts and turn adjusting screw 1/4 turn counter-

clockwise. Retighten bar clamp nuts.

• If chain is too loose, it will sag below the guide bar

(Figure 42).

_ ..... Sag

Figure 42 :

Loading ...

Loading ...

Loading ...