Loading ...

Loading ...

Loading ...

CUSTOMER RESPONSIBILITIES

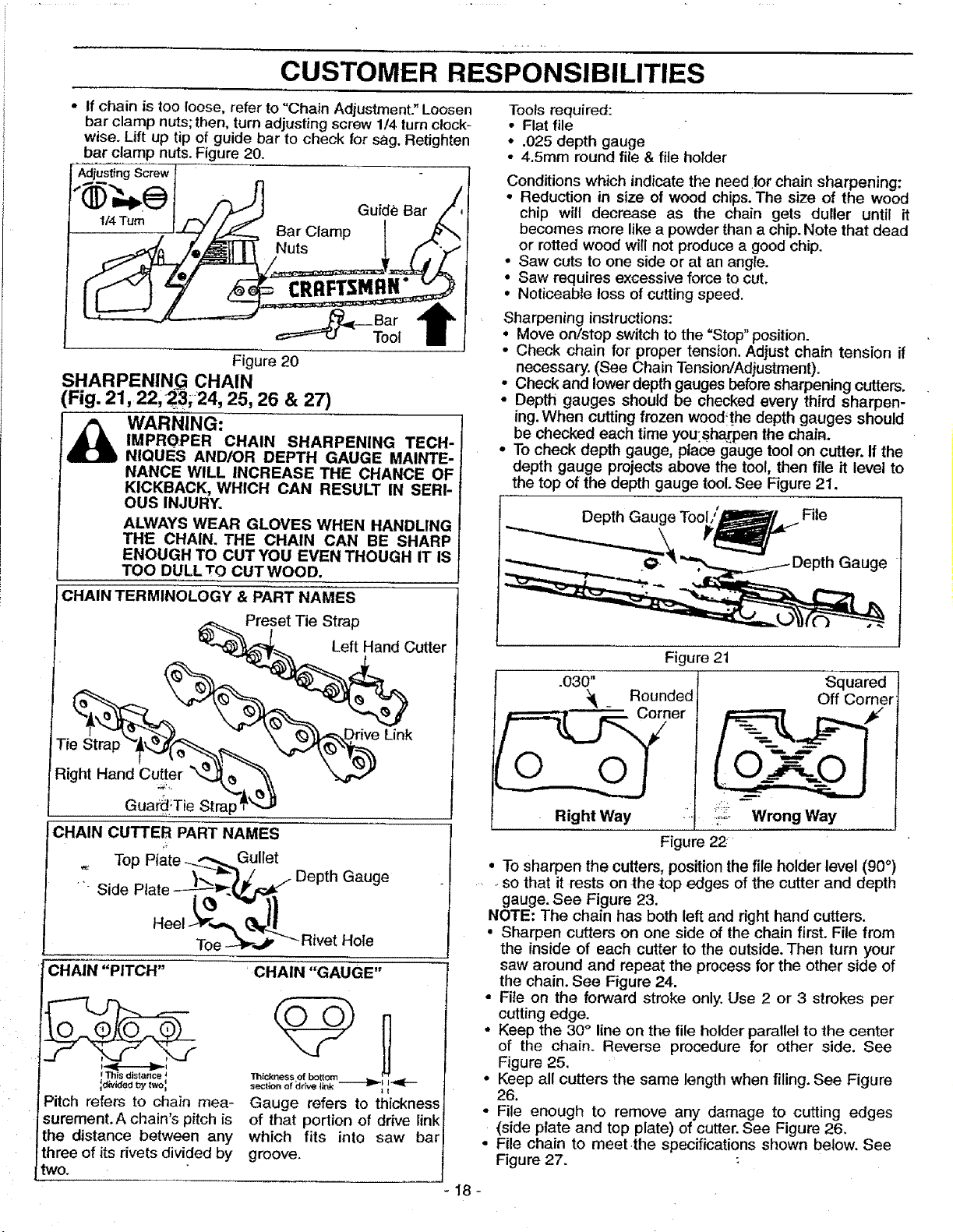

• If chain is too loose, refer to "Chain Adjustment." Loosen

bar clamp nuts; then, turn adjusting screw 1/4 turn clock-

wise. Lift up tip of guide bar to check for sag. Retighten

bar clamp nuts. Figure 20.

Adjusting Screw

1/4 Turn

Bar Clamp

Nuts

CRRFTSMRN"

Bar

Tool

Figure 20

SHARPENIN_ CHAIN

(Fig. 21,22,23,24 , 25, 26 & 27)

WARNING:

IMPROPER CHAIN SHARPENING TECH-

NIQUES AND/OR DEPTH GAUGE MAINTE-

NANCE WILL INCREASE THE CHANCE OF

KICKBACK, WHICH CAN RESULT IN SERI-

OUS INJURY.

ALWAYS WEAR GLOVES WHEN HANDLING

THE CHAIN. THE CHAIN CAN BE SHARP

ENOUGH TO CUT YOU EVEN THOUGH IT IS

TOO DULLTO CUTWOOD.

CHAIN TERMINOLOGY & PART NAMES

Preset Tie Strap

Left Hand Cutter

FieStrap Drive Link

Right Han: ..: "e _trap

CHAIN CUTTER PART NAMES

,_ Top Gullet

Depth Gauge

Hole

CHAIN "GAUGE"

Pitch refers to chain mea-

surement. A chain's pitch is

the distance between any

three of its rivets divided by

two.

Tl_ckness of bottom mj=._ I i_.,=r_

section of _idve tink _= I_

Gauge refers to thickness

of that portion of drive link

which fits into saw bar

groove.

Tools required:

• Flat file

• .025 depth gauge

• 4.5mm round file & file holder

Conditions which indicate the need for chain sharpening:

• Reduction in size of wood chips. The size of the wood

chip will decrease as the chain gets duller until it

becomes more like a powder than a chip. Note that dead

or rotted wood will not produce a good chip.

• Saw cuts to one side or at an angle.

• Saw requires excessive force to cut.

• Noticeable loss of cutting speed.

Sharpening instructions:

• Move on/stop switch to the "Stop" position.

• Check chain for proper tension. Adjust chain tension if

necessary. (See Chain Tension/Adjustment).

• Check and lower depth gauges before sharpening cutters.

• Depth gauges should be checked every third sharpen-

ing. When cutting frozen wood!he depth gauges should

be checked each time you_sharpen the chain_

• To check depth gauge, place gauge tool on cutter, If the

depth gauge projects above the tool, then file it level to

the top of the depth gauge tool. See Figure 21.

Depth Gauge

File

Figure 21

.030" Squared

:_ _ Rounded Off Corner

ner

Right Way £_ _i£2 Wrong Way

Figure 22

• To sharpen the cutters, position the file holder level (90°)

so that it rests on the top edges of the cutter and depth

gauge. See Figure 23.

NOTE: The chain has both left and right hand cutters.

• Sharpen cutters on one side of the chain first. File from

the inside of each cutter to the outside. Then turn your

saw around and repeat the process for the other side of

the chain. See Figure 24.

• File on the forward stroke only. Use 2 or 3 strokes per

cutting edge.

• Keep the 30° line on the file holder parallel to the center

of the chain, Reverse procedure for other side. See

Figure 25.

• Keep all cutters the same length when filing, See Figure

26,

• File enough to remove any damage to cutting edges

(side plate and top plate) of cutter. See Figure 26,

File chain to meet the specifications shown below, See

Figure 27.

Loading ...

Loading ...

Loading ...