Loading ...

Loading ...

Loading ...

Part number 550-100-325/0419

77

AquaBalance

®

Series 2 Wall Mount Gas-fired Water Boiler – Boiler Manual

32 Startup (continued)

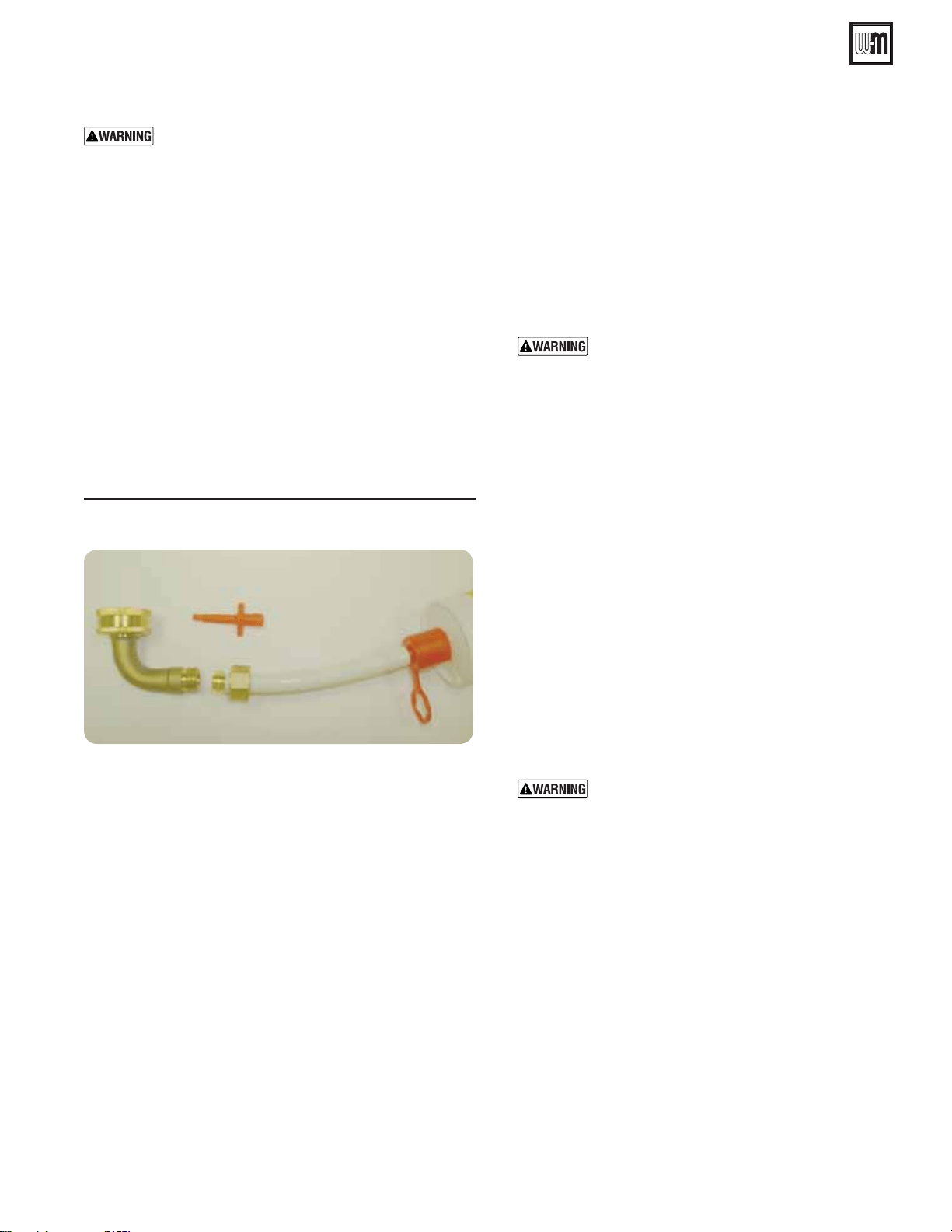

Figure 102

X100 inhibitor is required

1. It is required that the boiler have Sentinel X100 inhibi-

tor added to the system to prevent damage to the boilers’

heat exchanger. Failure to comply may result in accelerated

corrosion of the heat exchanger and system components.

See Replacement Parts section at the end of this manual for

ordering information.

2. After filling the system as directed in this manual, and the air

purge has been completed, release the system water pressure

to 0 psi. Drain a small amount of water out of a convenient

boiler drain to insure the system water pressure is at 0 psi.

Use a (field supplied-if needed) Dishwasher elbow / hose 3/4

to 3/8 compression adapter (See Figure 102 below) to the

white Sentinel hose, and screw it to the tube of Sentinel X100.

Insert it into your caulk gun, and fit the washing machine

hose adapter to a boiler drain connection. Open the drain,

and inject the complete tube of X100 to the system. Close the

drain valve, and remove the injection fitting.

3. Fill system water to required pressure, and start a heating

zone to circulate system water. Allow time for the water to

circulate and mix. Then check the inhibitor level with a test

kit. Add additional inhibitor if necessary.

Check/verify water chemistry

1. The system may have residual substances that could affect

water chemistry.

2. After the system has been filled and leak tested, verify water

pH and chloride concentrations are acceptable.

3. Verify antifreeze concentration, if used.

4. Follow the instructions on the Sentinel test kit to sample the

system water and verify inhibitor concentration.

Check inhibitor concentration

annually

1. Test the pH of a sample of system water at least annually.

The pH of the water mixture must be between 7.0 and 8.5.

(Or use the Sentinel inhibitor test kit to check concentra-

tion.)

2. If pH is outside this range (or inhibitor test kit indicates

low level), the inhibitor level may not be sufficient to pre-

vent corrosion.

3. Test antifreeze concentration.

Test antifreeze concentration at least annually.

If concentration is low, add antifreeze or drain

system and refill with correct mixture.

4. Follow instructions on antifreeze container to determine

the amount of antifreeze needed. exceed 50% by

volume concentration of antifreeze.

Check inhibitor level after adjustments are made.

Check thermostat circuits

1. Disconnect wires connected to the thermostat terminals

(see Field wiring, beginning on page 52 for low voltage

terminal locations and application information). Mark

the wires before removing to avoid wiring errors when

re-connecting them.

2. Connect a voltmeter across each pair of incoming wires.

Close each thermostat, zone valve and relay in the external

circuits one at a time and check the voltmeter reading across

the incoming wires.

3.

4. If a voltage does occur under any condition, check and

correct the external wiring.

to 3-wire zone valves

. This could cause con-

trol damage.

5. Once the external thermostat circuit wiring is checked and

corrected if necessary, reconnect the external thermostat

circuit wires.

Loading ...

Loading ...

Loading ...