Loading ...

Loading ...

Loading ...

. ii iiiiiii ii IIIIIHIIIIIIIIIIIII II Jill III IIII IIIIIII IIH IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII •

"1 _m,r .... ,, ,,,,,I_UII,I,I I I .=, _,,, i i

DI

Wear protective gloveswhan handltng

or _ yoursaw. Thechain ISsharpandcan _.t

you even when it Isnot movingl

• Yoursaw isequipped with a Reduced-KIckbeck

Guide Bar and a Low-Kickbeck Chain.

• Use onlythe Reduced-Kickback GuideBarand

Low-Kickback Chain specified for your chain

s_rwmodel when replacing these parts. See

"Specifications:'

z

1 AWARNING

Do not start engine without guide bar end chain com-

pletMy asumbisd. Otherwise, thedutch can comeoff

and serious'Injury can moult.

1. Tumtheadjustingscrewcounterclockwisetomove

theadjustingpinalmostasfarasitwillgotother_.

Figure10.

2. Mounttheslottsdendoftheguidebaroverthebar

Figure 8

4.

.

7.

Figure 9

E. CHAIN TENSION

• Correct chain tension is very important:

--a loose chain wilt wear the bar and itself.

--a loose chain can jump off the bar while

you are cutting.

--a tight chain can damage the saw and/or

break.

• The chain stretches during use, especially

when new. Check tension:

each timethesaw isused

-- more t_requentiywhen the chainisnew

as thechain warms up tonormaloperatingtem-

perature

• Chain tensioning procedure:

NOTE: The bar clamp nuts mustbe no more than

finger tight to tension the chain correctly.

NOTE: Holdup the tip of the Guide Bar through

step 4.

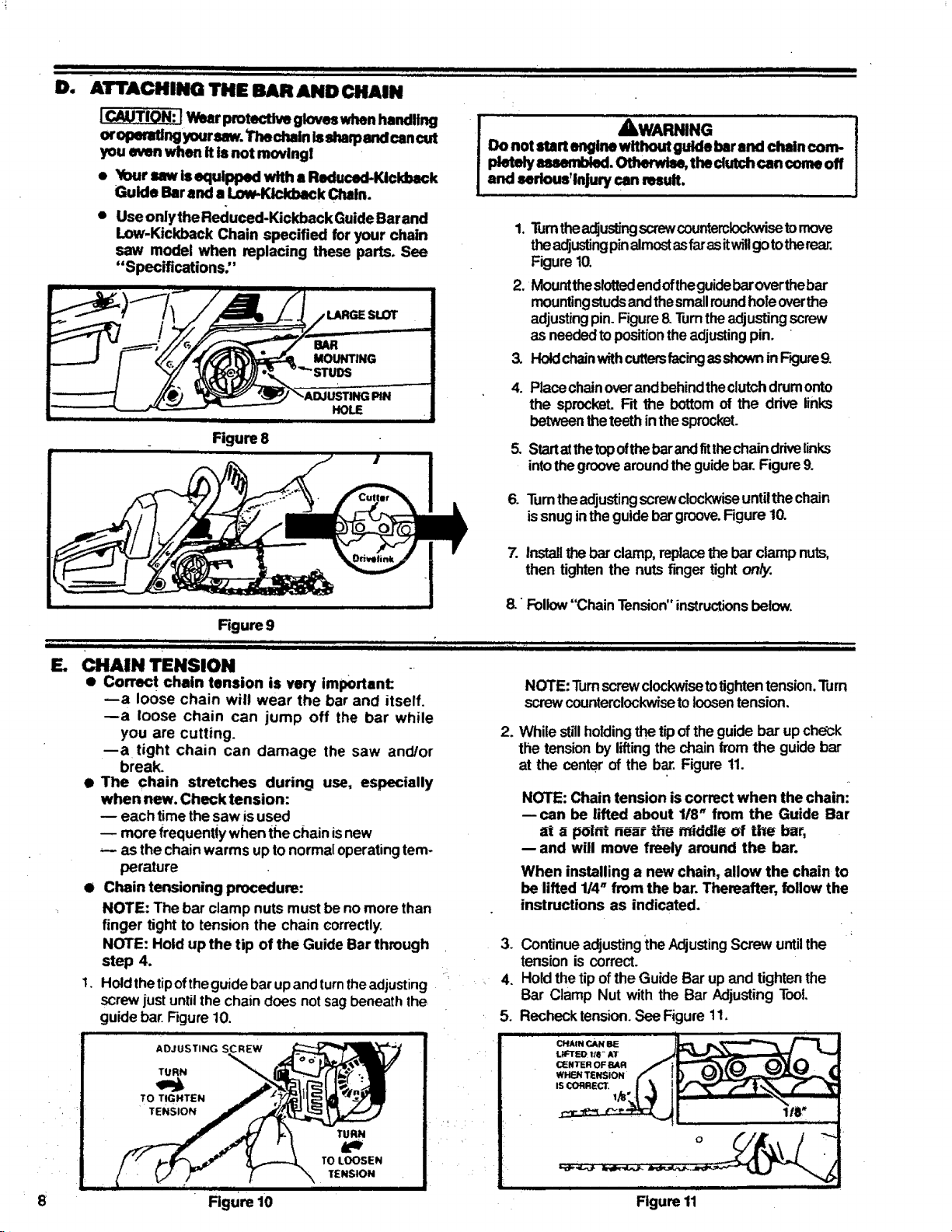

1. Holdthetipoftheguide barupandturntheadjusting

screwjust untilthe chain does notsag beneaththe

guide bar.Figure10.

ADJUSTING SCREW

TURN

TO LOOSEN

TENSION

TURN

TO TIGHTEN

TENSION

Figure 10

.

mountingstudsandthesmallroundholeoverthe

adjusting pin.Figure8 Turntheadjustingscrew

as neededtopositiontheadjustingpin.

HoldchainwithcuttersfacingaSshowninFK:jure9.

Placechainoverandbehind theclutchdrumonto

the sprocket.Fit the bottomof the ddve links

between theteethinthesprocket.

Startatthetopofthebarandfitthechaindrivelinks

into thegroovearoundtheguidebar.Figure9.

Tumthea_usting screwclockwiseuntilthechain

issnugintheguide bargroove.Figure10.

installthebar clamp,replace thebar clamp nuts,

then tightenthe nuts finger tighton_

8."Foliow"ChainTension"instructionsbelow.

IIIIIHIII

NOTE: Turnscrewclockwisetotighten tension.Turn

screwcounterclockwisetoloosentension,

While still holdingthetipofthe guidebar up che_k

the tension by liftingthe chainfromthe guide bar

at the center of the b_ Figure 11.

NOTE: Chaintension is correct when the chain:

--can be lifted about 1/8" from the Guide Bar

at a point neat the middle of the bar,

--and will move freely around the bar.

When installing a new chain, allow the chain to

be lifted 114"from the bar, Thereafter, follow the

instructions as indicated,

3. ContinueadjustingtheAdjustingScrew untilthe

tension is correct.

4. Holdthetip ofthe Guide Bar up and tightenthe

Bar Clamp Nut with the Bar Adjusting Tool.

5. Rechecktension.See Figure 11.

11

Figure 11

Loading ...

Loading ...

Loading ...