Loading ...

Loading ...

Loading ...

O. liAR AND CHAIN LUBRICANT

3. ADJUSTING THE AUTOMATIC OILER

.

o

• The Guide Bar and Cuttingchain mquirecon.

tinuous lubricationtoremaininoperating con*

dition. Lubricationisprovidedbythe automatic

oilersystemwhentheoiltankiskeptfilled.

-- Lack ofoil willquloldyruinthebarandchain.

-- Toollttle oil wiltcauseoverheatlngshownby

smokecomingfromthechainand/ordiscolora-

tionoftheguidebar rails

e

Use Sears Bar and Chain Lubricant (#71-36554-

gal. or #71-36556-qt.) to fillthe oil tank. CleanSAlE

3(7,Noilmay alsobe used,butislesseffective.Never

use waste oilfor 1hispurpose.

• Infreezingweatheroilwillthicken, makingitneces-

sary tothin bar and chainoil with asmall amount

of#1 Diesel FuelorKemsene. Barandchainoilmust

be free flowingforadequatelubrication.

usE THE FOLLOWING:

30° or above -- Lubricantundiluted

30° to 0°F, -- 950/oLubricant to 5%

#1 Diesel fuel or Kerosene.

BelowOOF. -- 90% Lubricant to 10%

#1 Diesel fuelor Kerosene.

HOW TO RLL THE OIL TANK

a. Stoptheengine,

b. 7am sawon itssidewithoilcap up.Figure12.

c, Loosencapslowlyandwaitforpressureinthetank

tobe releasedbeforeremovingthecap.

d. Fillthe oiltank,

e. Replace theoilcapsecurely.

!

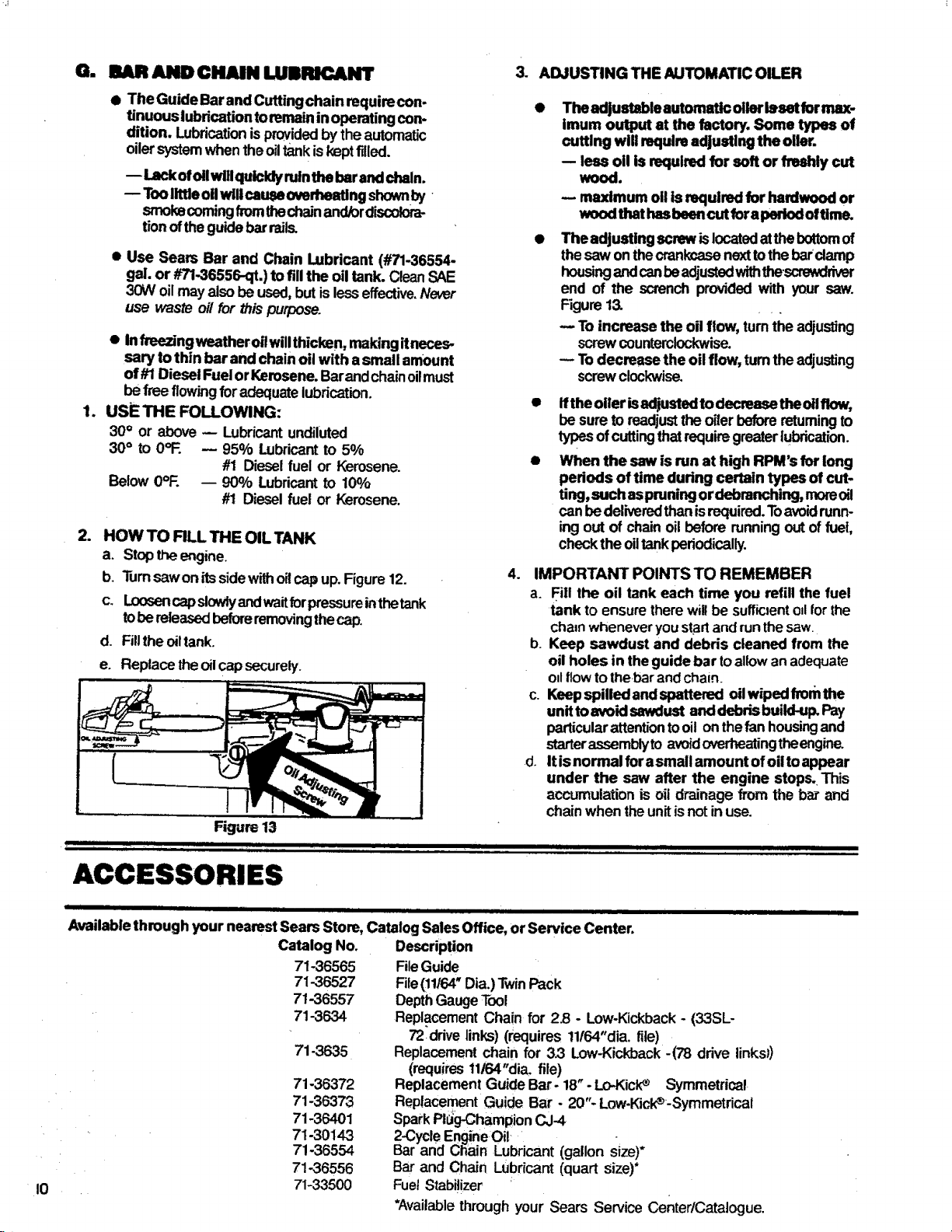

Figure 13

111"1 "1 m l_ IIIIIIIIIIIIIIII II 11111/ IIII I I1!11111// I IIIIIIII

.

e

e

e

o

The adjustable automatic oiler_sot for max-

imum output at the factory. Some types of

cutting will requireadjusting the oiler.

-- less oil is required for soft or freshly cut

wood.

-- maximum oil isrequired for bardwood or

woodthathasbeancutfor aperiodoftime.

The adjusting screwislocatedatthebottomof

thesaw onthecrankcasenexttothe barclamp

housingandcanbeadjustedwiththe,screwdriver

end of the screnchprovided with yoursaw.

Figure13. , _,

-- To increase the oil flow, turnthe adjusting

screwcounterclockwise.

-- Todecrease the oil flow, turntheadjusting

screwclockwise.

tftheoiler isadjustedto decrease theoilflow,

be sureto readjustthe oilerbeforereturningto

typesofcuttingthatrequiregreaterlubrication.

When the saw is run at high RPM's for long

pedods of time during certain types of cut-

ring,such aspmning or debmnching, moreoil

can be deliveredthanisrequired.Toavoidrunn-

ing out of chainoil before runningoutof fuel,

checkthe oiltankperiodically.

IMPORTANT POINTS TO REMEMBER

a. Fill the oil tank each time you refill the fuel

tank to ensure therewillbe sufficientodfor the

chainwheneveryoustartand runthesaw

b. Keep sawdust and debris cleaned from the

oil holes in theguide bar toallowan adequate

oilflow tothebar and chain.

c. Keepspilled and spattered oUwiped fromthe

unittoavoid sawdust and debdsbuild-up.Pay

particularattention tooil onthefanhousingand

starterassemblytoavo{doverheatingtheengine.

d. It isnormal for asmail amount of oiito appear

under the saw after the engine stops. This

accumulation is oil drainage from the bar and

chainwhen theunitisnot inuse.

I I /I I IJlIIlU I Jill

ACCESSORIES

10

II i I i iiii i i HI , ...............................

Available through your nearest Sears Store, Catalog SalesOffice, or Service Center.

Catalog No.

71-36565

71-36527

71-36557

71-3634

71-3635

71-36372

71-36373

71-36401

71-30143

71-36554

71.,36556

71-33500

Description

FileGuide

File(11/64"Dia.)TwinPack

Depth GaugeTool

Replacement Chain for 2,8 - Low-Kickback - (33SL-

72 drive links) (requires 11/64"dia. file)

Replacement chain for 33 Low-Kickback -(78 drive linksl)

(requires 11i64"dia. file)

Replacement Guide Bar- 18" -Lo-Kick_ Symmetrical

Replacement Guide Bar - 20"-Low-Kicl_-Symmetrical

SparkPl(_g-ChampionCJ4

2-CycleEngineOil-

Bar and Chain Lubricant (gallon size)*

Bar and Chain Lubricant (quart Size)*

Fuel Stabilizer

*Available through your Sears Service center/Catalogue,

Loading ...

Loading ...

Loading ...