Loading ...

Loading ...

Loading ...

LowerDriveBelt

NOTE: Proper removal of the lower drive belt requires

the removal of several tractor components. Read

through the following procedure prior to attempting ff to

determine if you feel you could successfully complete it.

If you don't, see an authorized MTD service dealer to

have the belt changed.

IMPORTANT: Note the routing of the lower drive belt

around all the pulleys and the belt keepers BEFORE

performing the following steps.

Locate the variable-speed pulley through the

battery tray opening. See Figure 19.

Remove the variable-speed pulley by loosening the

hex bolt that secures it to the transmission. Use a

second wrench to hold the hex nut on the bottom

side of the pulley.

Slide the lower drive belt off of the varia ble-speed

pulley as you lift the pulley up and out through the

battery tray opening.

Remove the rear idler pulley from the double- idler

bracket while unrouting the belt from around both

the rear and the front idler pulley. Refer to Figure

19.

Remove the hex bolt from the center of the engine

pulley (or electric PTO clutch, if so equipped) and

gently lower it off of the engine crankshaft. Be

careful not to lose any washers or spacers which

may be found on top of the engine pulley.

IMPORTANT: When remounting the engine pulley (or

electric PTO clutch), torque the center hex bolt to

between 38 foot-pounds and 50 foot-pounds.

Remove the drive belt by feeding it from both ends

toward the front idler pulley on the double-idler

bracket. See Figure 19.

Reassemble by following the above steps in

reverse order.

Route the replacement belt around the pulleys, belt

keepers and keeper pins EXACTLY as the old one

was routed. Refer to Figure 19.

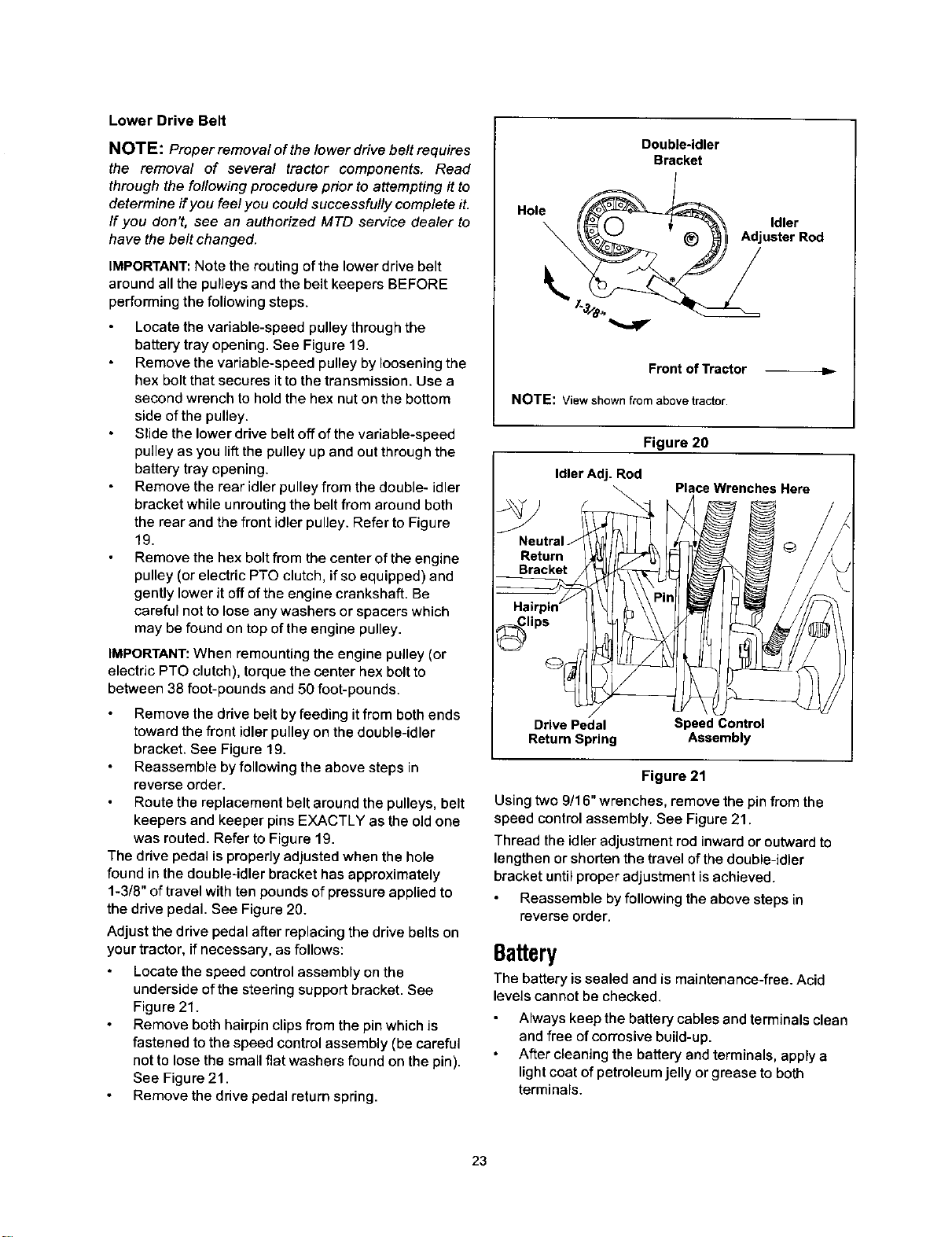

The drive pedal is properly adjusted when the hole

found in the double-idler bracket has approximately

1-3/8" of travel with ten pounds of pressure applied to

the drive pedal. See Figure 20.

Adjust the drive pedal after replacing the drive belts on

your tractor, if necessary, as follows:

Locate the speed control assembly on the

underside of the steering support bracket. See

Figure 21.

Remove both hairpin clips from the pin which is

fastened to the speed control assembly (be careful

not to lose the small flat washers found on the pin).

See Figure 21.

Remove the drive pedal return spring.

Double-idler

Bracket

Hole _ AdjuldlerrRod

Front of Tractor

NOTE: Viewshownfrom abovetractor.

Figure 20

Idler Adj. Rod

\

Neutral J

Return

Bracket

lips

Drive Pedal Speed Control

Return Spring Assembly

Place Wrenches Here

Figure 21

Using two 9/16" wrenches, remove the pin from the

speed control assembly. See Figure 21.

Thread the idler adjustment rod inward or outward to

lengthen or shorten the travel of the double-idler

bracket until proper adjustment is achieved.

Reassemble by following the above steps in

reverse order.

Battery

The battery is sealed and is maintenance-free. Acid

levels cannot be checked.

Always keep the battery cables and terminals clean

and free of corrosive build-up.

After cleaning the battery and terminals, apply a

light coat of petroleum jelly or grease to both

terminals.

23

Loading ...

Loading ...

Loading ...