Loading ...

Loading ...

Loading ...

USING HOLD DOWN/PUSH BLOCKS

Refer to Figure 15

• Always use hold-down/push-blocks when jointing, or

rabbeting wood that is narrower than 3", planing

wood thinner than 3"

Figure 15 - Feeding with Push Blocks

• Grasp the hold-down/push-blocks firmly

• Position the push-blocks flat on top of workpiece and

push the workpiece down against the table

• Use a hand-over-hand motion to maintain control

over the workpiece at all times

• When planing workpiece between 1__3/4.and nar-

rower than the push-blocks, tilt the push-blocks so

that it clears the cutterhead guard while feeding

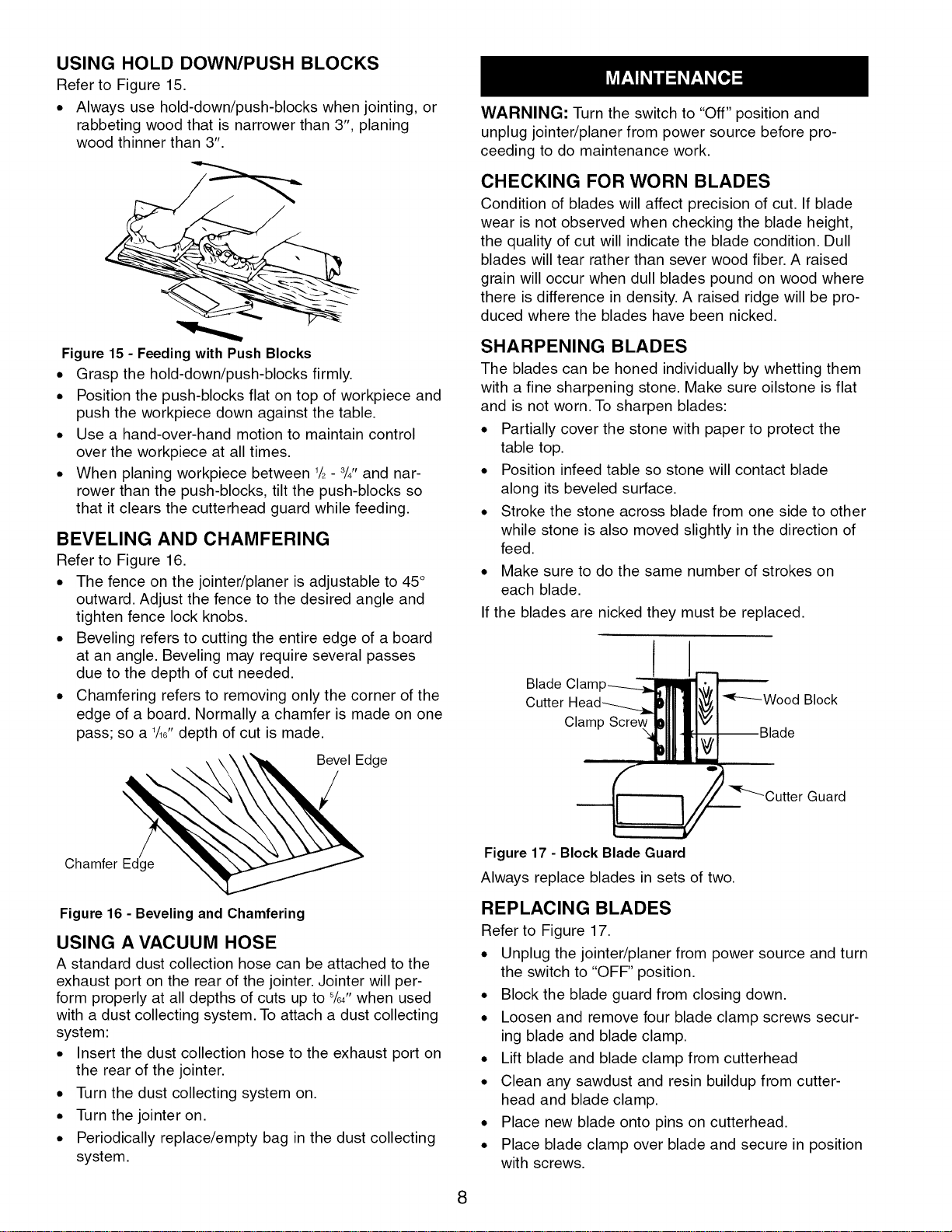

BEVELING AND CHAMFERING

Refer to Figure 16.

• The fence on the jointer/planer is adjustable to 45 °

outward Adjust the fence to the desired angle and

tighten fence lock knobs

• Beveling refers to cutting the entire edge of a board

at an angle Beveling may require several passes

due to the depth of cut needed

• Chamfering refers to removing only the corner of the

edge of a board Normally a chamfer is made on one

pass; so a _/_6"depth of cut is made

Bevel Edge

WARNING: Turn the switch to "Off" position and

unplug jointer/planer from power source before pro-

ceeding to do maintenance work.

CHECKING FOR WORN BLADES

Condition of blades willaffect precision of cut. If blade

wear is not observed when checking the blade height,

the quality of cut will indicate the blade condition Dull

blades will tear rather than sever wood fiber A raised

grain will occur when dull blades pound on wood where

there is difference in density A raised ridge will be pro-

duced where the blades have been nicked

SHARPENING BLADES

The blades can be honed individually by whetting them

with a fine sharpening stone Make sure oilstone is flat

and is not worn To sharpen blades:

• Partially cover the stone with paper to protect the

table top

• Position infeed table so stone will contact blade

along its beveled surface

• Stroke the stone across blade from one side to other

while stone is also moved slightly in the direction of

feed

• Make sure to do the same number of strokes on

each blade

If the blades are nicked they must be replaced

Blade Clam

Cutter

Clamp

Guard

Chamfer Edge

Figure 16 - Beveling and Chamfering

USING A VACUUM HOSE

A standard dust collection hose can be attached to the

exhaust port on the rear of the jointer Jointer will per-

form properly at all depths of cuts up to %/' when used

with a dust collecting system To attach a dust collecting

system:

• Insert the dust collection hose to the exhaust port on

the rear of the jointer

• Turn the dust collecting system on

• Turn the jointer on

• Periodically replace/empty bag in the dust collecting

system

Figure 17 - Block Blade Guard

Always replace blades in sets of two.

REPLACING BLADES

Refer to Figure 17.

• Unplug the jointer/planer from power source and turn

the switch to "OFF" position

• Block the blade guard from closing down

• Loosen and remove four blade clamp screws secur-

ing blade and blade clamp

• Lift blade and blade clamp from cutterhead

• Clean any sawdust and resin buildup from cutter-

head and blade clamp

• Place new blade onto pins on cutterhead

• Place blade clamp over blade and secure in position

with screws

8

Loading ...

Loading ...

Loading ...