Loading ...

Loading ...

Loading ...

Level

the

washer

1.

Tilt

washer

forward,

raising

rear

legs

25

mm

(1")

off

of

floor.

To

adjust

rear

self-leveling

legs,

gently

lower

washer

to

floor.

2.

Check

levelness

of

the

washer

by

placing

a

carpenter’s

level

on

top

of

the

washer,

first

side

to

side;

then

front

to

back.

3.

If

washer

is

not

level,

adjust

the

front

legs

up

or

down.

Make

final

check

with

level.

4.

When

washer

is

level,

use

a

wrench

to

turn

the

nuts

on

front

legs

up

tightly

against

washer

base.

If

nuts

are

not

tight

against

washer

base,

the

washer may

vibrate.

1.

Check

the

electrical

requirements.

Be sure

that

you

have

the

correct

electrical

supply

and

the

recommended

earthing

method.

2.

Check

that

all

parts

are

now

installed.

If

there

is

an

extra

part,

go

back

through

the

steps

to

see

which

step

was

skipped.

3.

Turn

on

water

taps

and

check

for

leaks.

Tighten

couplings

if

there

is

leaking.

Do

not

overtighten;

this

could

cause

damage

to

the

taps.

4.

Be

sure

you

have

all

of

your

tools.

§.

Check

that

the

shipping

strap

was

removed

from

the

back

of

the

washer

and

used

to

secure

the

drain

hose.

If

entire

strap

is

not

removed,

washer may

vibrate

and

be noisy.

6.

Plug

power

supply

cord

into

an

earthed

outlet.

NOTE:

On

some

models,

during

factory

testing,

the

timer

is

advanced

partially

into

the

cycle,

causing

the

start

button

to

be

depressed.

Allow

timer

to

advance

to

the

end

of

the

cycle.

When

the

cycle

is

complete,

the

timer

will

reset

and

the

start

button

will

return

to

the

start

position.

If

the

timer

is

not

allowed

to

advance

to

the

end

of

the

first

cycle

and

reset,

the

wash

load

will

not

be

completed.

Checklist

for

washer

operation

Check

the

following

if

the

washer

is

not

operating

properly:

.

Power

supply

cord

is

plugged

in.

.

Circuit

breaker

is

not

tripped

or

fuse

is

not

blown.

.

Timer

has

been

advanced

to

start

of

a

cycle.

.

Water

taps

are

turned

on.

.

Inlet

and

drain

hoses

are

not

kinked.

.

Washer

lid

is

closed.

.

Inlet

valve

can

freeze

if

not

protected

from

the

weather.

.

Suds

level.

Excess

suds

will

slow

the

spin

and

cause

poor

rinsing.

Operate

the

washer

through

a

complete

cycle

with

no

detergent.

Use

less

detergent

or

a

controlled

suds

type

detergent

in

future

loads.

aon

©

OF

Bb @® ND

=

if

you

need

assistance:

Contact

your

authorized

Maytag®

Commercial

Laundry

distributor.

To

locate

your

authorized

Maytag®

Commercial

Laundry

distributor,

or

for

web

inquiries,

visit

www.MaytagCommercialLaundry.com.

When

you

call,

you

will

need

the

washer

model

number

and

serial

number.

Both

numbers

can

be

found

on

the

model/

serial-rating

plate

located

under

the

lid.

8

PNT

ite

Gh)

6

Fire

Hazard

No

washer

can

completely

remove

oil.

Never

place

items

in

the

washer

that

are

dampened

with

gasoline

or

other

flammable

fluids.

Do

not

dry

anything

that

has

ever

had any

type

of

oil

on

it

(including

cooking

oils).

Doing

so

can

result

in

death,

explosion,

or

fire.

Typical

full

load

sizes

2

pillowcases

Load

Type

|

Loading

Load

Type

|

Loading

Suggestion Suggestion

Mixed

Load

|

3

double

sheets

|

Heavy

Work

|

3

pair

pants

4

pillowcases

Clothes

3

shirts

6

pair

shorts

1

coverall

8

T-shirts

4

pair

jeans

2

shirts

1

overall

2

blouses

8

handkerchiefs

Permanent

|

2

double

or

Knits

3

blouses

Press

1

king-size

sheet

4

slacks

1

tablecloth

6

shirts

1

dress

4

tops

1

blouse

4

dresses

2

slacks

3

shirts

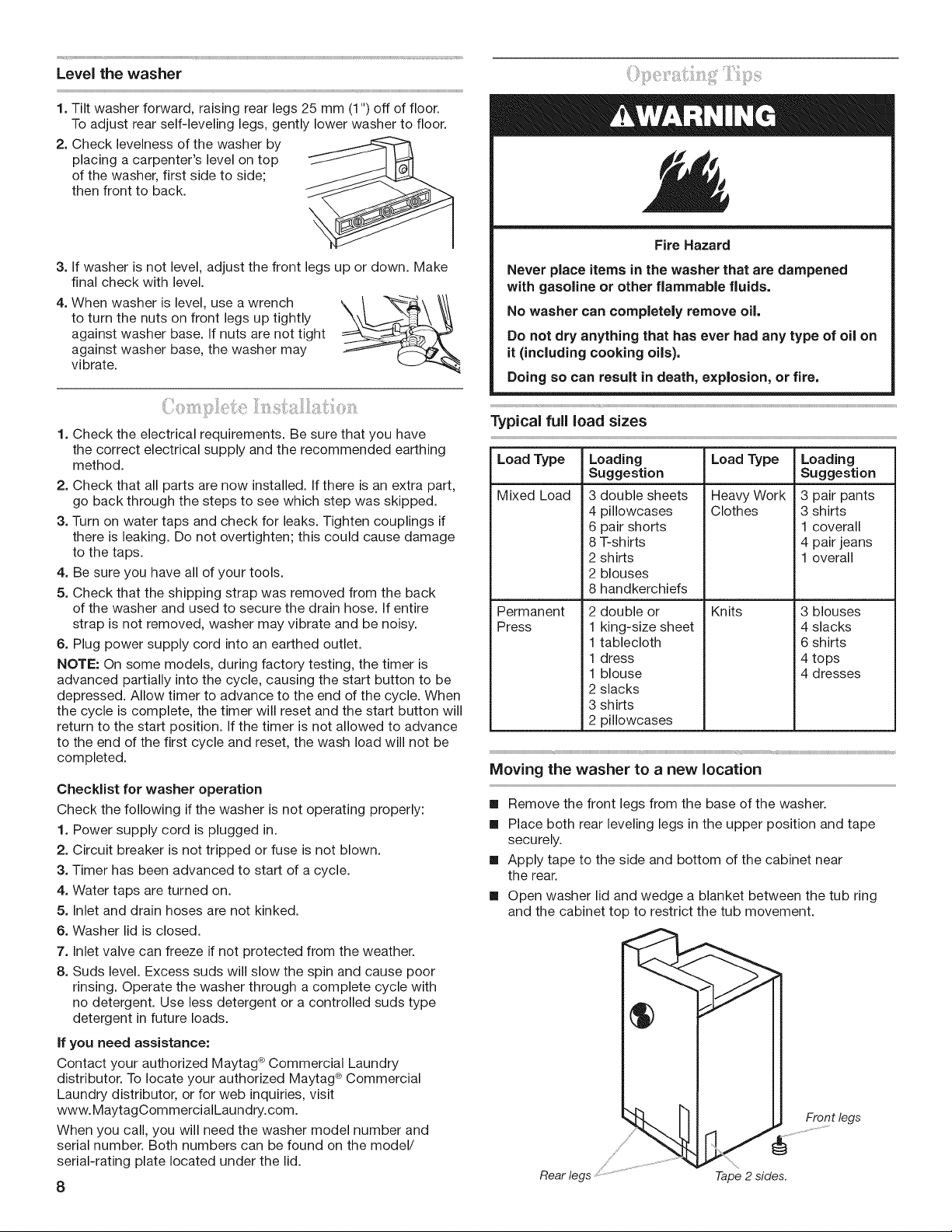

Moving

the

washer

to

a

new

location

@

Remove

the front

legs

from

the

base

of

the

washer.

@

Place

both

rear

leveling

legs

in

the

upper

position

and

tape

securely.

@

Apply

tape

to

the

side

and

bottom

of

the

cabinet

near

the

rear.

@

Open

washer

lid

and

wedge

a

blanket

between

the

tub

ring

and

the

cabinet

top

to

restrict

the

tub

movement.

Rear

legs

é

Fganennone

Tape

2

sides.

Front

legs

Loading ...

Loading ...

Loading ...