Loading ...

Loading ...

Loading ...

BEFOREEACHUSE

Checkwaterinletscreenfordamage.

• Checkhighpressurehoseforleaks.

Checkchemicaltanksandfillersfor damage.

• Check gun and wand assemblyfor leaks.

• Purge pumpofair and contaminants.

• Check engine oil level.

CLEANING SYSTEM MAINTENANCE

Check and Clean Inlet Screen

Examine garden hose inletscreen. Clean if if is

cloggedor replaceifit istom.

Check High Pressure Hose

High pressure hosescan develop leaksfrom wear,

kinking,or abuse, inspecthose beforeeach use.

Check for cuts, leaks, abrasions, bulgingof cover, or

damage or movement ofcouplings, ffany of these

conditionsexist, replace hose immediately.

A DANGER: Never repair a highpressure hose.

Replace with hosethat meetsthe minimum

pressurerating ofyour cleaningsystem

Check Chemical Reservoirs

Tank coversshouldsnap cleanlyontotank. Ensure

chemicallabelscorrectlyidentifytank contents.

Ensurethat the System Rinsetank isfilled with clean

water. Ensurethat Dial-A-CleanerTM selectorknob

rotatesfreely between each position.Examine the

tanks and replaceifthe filter is clogged

Check Gun and Wand

Examine:h0seconnectionto gun and make sure itis

secure.Test triggerby pressingif and making sure it

springsback intoplace when you release it. Put safety

latch in UP positionand test trigger.You should not be

able topress trigger.Replace gun immediatelyif it

fails any ofthese tests.

Purge Pump of Air and Contaminants

To removethe air from the pump, followthese steps:

• Set up the cleaningsystem as described in the

ASSEMBLY sectionand connect the water supply.

• Remove thewand extensionfromthe gun.

• Pullthetriggeron the gun and holduntil a steady

streamofwater appears.

To removethe contaminants from the pump, follow

these steps:

• Set upthe cleaningsystem as describedin the

ASSEMBLY section,and connect the water supply.

• Remove the nozzleattachmentfrom the gun.

Startthe engine according to instructionsin

OPERATION section.

• Pullthe triggeron the gunand hold.

• When thewater supplyis steadyand constant,

engage the safetylatch and refsstenthe nozzle

attachment.

Nozzle Maintenance

If the nozzlebecomes restrictedor cloggedwith

foreignmaterials,suchas dirt,excessivepump

pressure may develop.A partiallycloggednozzlecan

cause a pulsingconditionduring use.This generallyis

not a pumprelatedproblem,but rathera clogged or

partiallyrsstdctednozzle.

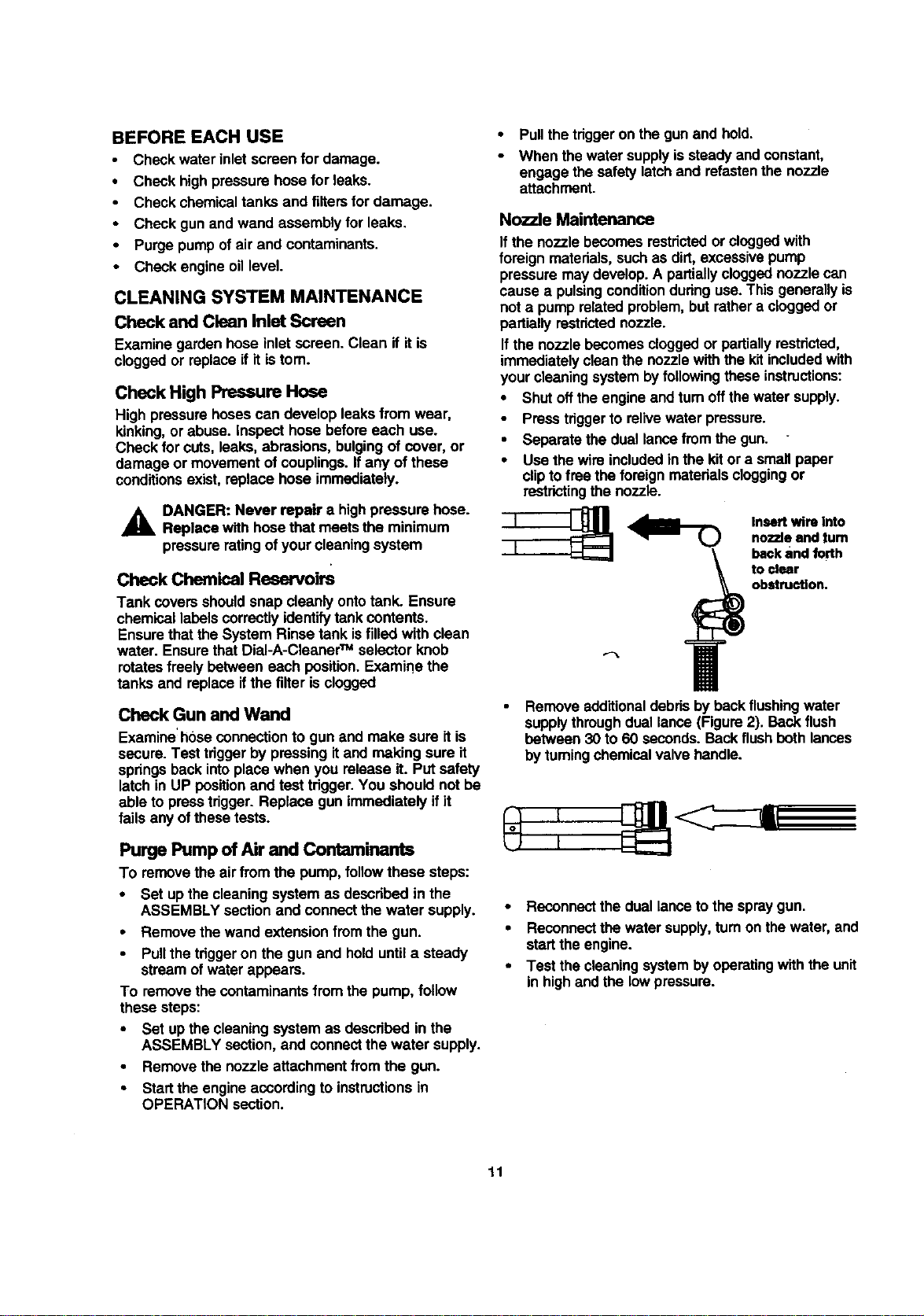

If the nozzle becomescloggedor partiallyrestricted,

immediatelycleanthe nozzlewiththe kitincludedwith

yourcleaningsystem byfollowingthese instructions:

• Shut offtheengine and tam offthe water supply.

Presstriggerto relivewater pressure.

• Separate the dual lancefrom the gun.

• Usethe wire includedin the kitor a small paper

cliptofree the foreign materialscloggingor

restrictingthe nozzle.

Insert wire Into

nozzle and tum

back and forth

to clear

obstruction.

Remove additionaldebrisby backflushingwater

supplythroughdual lance (Figure2). Back flush

between 30 to 60 seconds.Backflushbothlances

bytumingchemicalvalve handle.

• Reconnectthe dual lanceto the spraygun.

• Reconnectthe water supply,turnon thewater, and

startthe engine.

• Test thecleaningsystem byoperatingwith the unit

in highand the low pressure.

11

Loading ...

Loading ...

Loading ...