Loading ...

Loading ...

Loading ...

SPOOL REPLACEMENT

.......i. _op motorand UnplugpowerCord.

2. P,estmlnrearplate, pushintockbutton (lecatedon hub),and twist

hubcounter-clockwiseuntlllocklng tabsdlsengag_ Remo_ehub.

3. Remove spool fromassembly and removespring-from Spool.

4. Rewlndispoolfnaccordance with theInstructionsIncludedherein

(fig.6). or replace,spoolas approprlate_

5. Beforemlnst_illng spool be sureapproximately3 Inel_esoffine

exits spool between the_twofoam pads as shownIn fig.S.

6. install springon '_OP SIDE" of spool. See fig.5.

7. Insert linethin eyeletInhubassernbly and seat epdng end onto

center post Inside hubassembly.

NOTE: Make surelinedoesnot get trapped underspool,between

the spool and hub assembly, •

8._ Slidespoolandhubassemblyontomotorshaft.Manlpulateparts

- sltghtlytbobtaln pmp_;rallgnmenL LIftihg uponrear plate_align

lookingtabs onhubassembly with s!ots in rearplate and insert

• .tabs _nto slots until parts bottom. Rotate hub _assembly

_io0_ise Whlieres.tr_Intngth_ rearp|ate until all four i0_ing "

tabs are proped;yengaged;

9: RemoVedebris.from,underslde of your WEEDWACKEFL

IFLINE DOES NQTEEED "

t.-. Follow instructions 1.3 unde_:"_3pool Replacement:'

2_ Check to make. sure:llhe Iswound Indirection indicated

on spool,, " ""

3. Separate strandsof tangled line or install new line if

necessary.

4. In.spect foam pad for te_Lmof damage, replace if necessary.

5/ Check spring for damage and proper Installation."

6. Follow tnst(uetlons.5_thru .9 under "Spool Replacement."

FIG_5

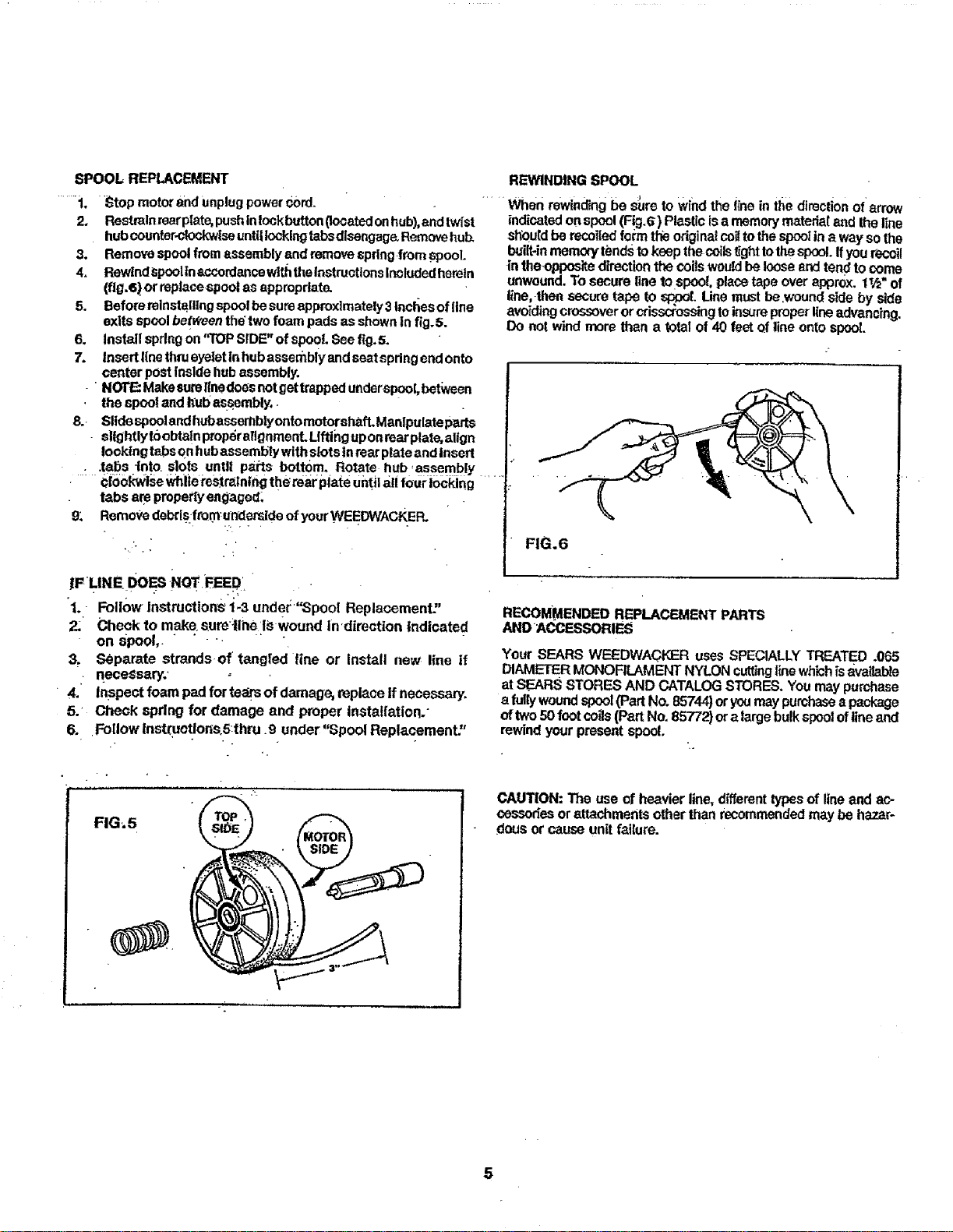

REWINDING SPOOL

..... When rewinding be s_re to Windthe line in the directionofarrow

indicated on spool (Fig.6) Plastic isa memorymaterial and the line

should be recededform the original coiltothe spoolin a way so the

built-inmemory tbndstokeep the coilstightto the spool, ifyou recoil

in theopposite direction the coils wouldbe loose and tend to come

unwound. To secure line tospool, place tape over approx. 1_,_"of

line, then secure tape to ,s_f. Line must be,wound side by side

avoidingcrossoveror crisscrossingtoinsureproperlineadvancing,

Do not wind more than a total of 40 feet Qfline onto spool.

FIGo6

RECOMMENDEDREPLACEMENTPARTS

ANDACCESSORIES

Your SEARS WEEDWACKER uses SPECIALLY TREATED .065

DIAMETER MONORLAMENT NYLON cuttingline whP..his available

at SEARS STORES AND CATALOG STORES, You may purchase

a fullywoundspool (PaR No. 80"744)oryoumay purchasea package

oftwo 50 foot co{Is(Part No, 85772) ora large bulkspool of lineand

rewind your present spool.

CAUTION: The useof heavierline,differenttypesof lineandac-

eessodesorattachments otherthanrecommendedmay behazar-

dousor causeunitfailure.

5

Loading ...

Loading ...

Loading ...