Loading ...

Loading ...

Loading ...

Section5: Maintenance

_ eforeinspecting,cleaningorservicingthemachine,shutoffengine,waitformovingpartstostop,disconnectspank

plugwireandmovewireawayfromspankplug.Removeignitionkey(electricstartmodels).

Failuretofollowtheseinstructionscanresultinseriouspersonalinjur/orpropertydamage.

BLADEBRAKEREPLACEMENT

Followthis procedureto installa new

bladebrake.

ToRemoveBladeBrake:

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Removebeltcoverasdescribedin

"Belt CoverRemoval"instructions.

3. Removehardware(G,Figure5-8)

securingbladebrake(H).

4. Removeold brake(H)from idler

arm (I).

ToInstall Brake:

1. Positionnewbrake(H) in placeon

idlerarm (I).

2. Centerbrakein sheavegrooveand

securebrake(H)with hardware(G)re-

movedearlier.

3. Reinstallbeltcoversecurely.

4. Testoperationof bladebrake(see

"BladeBrakeControlTest" in Operation

section).

BLADEDRIVEBELT

ADJUSTMENT

If thebladedrive beltis slippingdueto

lackof belttension,follow thesteps

below.

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Removebeltcoverasdescribedin

"Belt CoverRemoval"instructions.

3. With moweron levelground,adjust

bladecutting heightatabout3" (mea-

surefrom ground to flat portion of

blade).

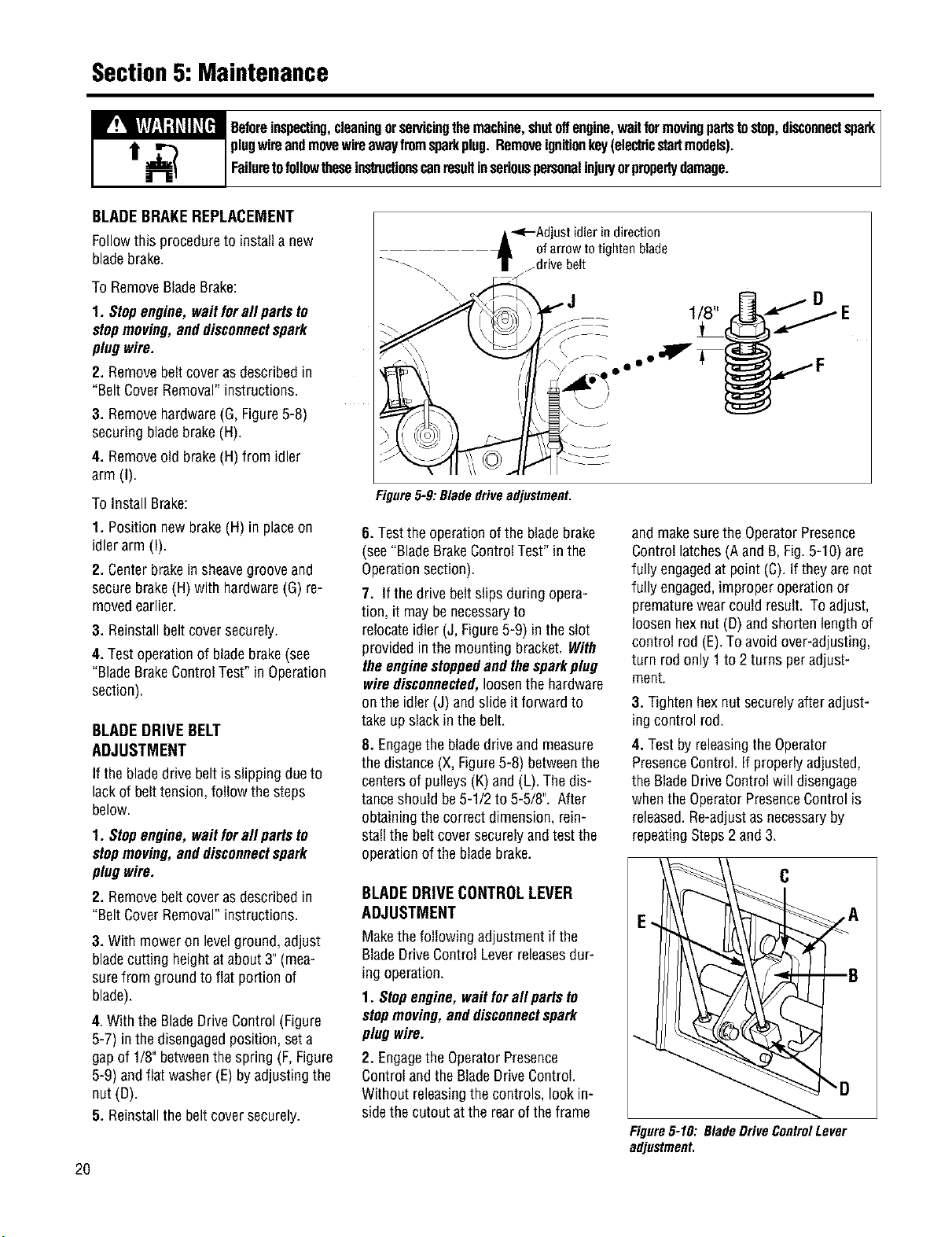

4. Withthe BladeDriveControl(Figure

5-7) inthedisengagedposition,seta

gapof 1/8" betweenthespring (F,Figure

5-9) andflat washer(E)byadjustingthe

nut(D).

5. Reinstallthe beltcoversecurely.

2O

-_--Adjust idlerin direction

of arrow to tighten blade

f drive belt

D

Figure5-9: Bladedriveadjustment.

6. Testthe operationofthe bladebrake

(see"BladeBrakeControlTest"in the

Operationsection).

7. If thedrive beltslips during opera-

tion, it maybenecessaryto

relocateidler (J, Figure5-9) intheslot

providedinthe mountingbracket. With

theenginestoppedandthesparkplug

wiredisconnected,loosenthehardware

onthe idler (J) andslideit forward to

take upslackinthe belt.

8. Engagethe bladedriveand measure

the distance(X,Figure5-8) betweenthe

centersof pulleys(K) and(L). Thedis-

tanceshould be5-1/2to 5-5/8". After

obtainingthecorrect dimension,rein-

stallthe beltcoversecurelyandtestthe

operationofthe bladebrake.

BLADEDRIVECONTROLLEVER

ADJUSTMENT

Makethefollowing adjustmentif the

BladeDriveControl Leverreleasesdur-

ing operation.

1. Stopengine,waitforall partsto

stopmoving,anddisconnectspark

plugwire.

2. Engagethe OperatorPresence

ControlandtheBladeDriveControl.

Withoutreleasingthe controls, lookin-

sidethe cutoutatthe rearof theframe

and makesurethe OperatorPresence

Controllatches(Aand B,Fig.5-10) are

fully engagedat point (C).If they arenot

fully engaged,improperoperationor

prematurewearcould result. To adjust,

loosenhexnut (D)andshorten lengthof

control rod(E).Toavoidover-adjusting,

turn rodonly 1 to 2 turns peradjust-

ment.

3. Tighten hexnutsecurelyafter adjust-

ingcontrol rod.

4. Testby releasingtheOperator

PresenceControl.If properlyadjusted,

the BladeDriveControlwill disengage

whentheOperatorPresenceControlis

released.Re-adjustasnecessaryby

repeatingSteps2 and3.

Figure5-10: BladeDriveControlLever

adjustment.

Loading ...

Loading ...

Loading ...