Loading ...

Loading ...

Loading ...

23

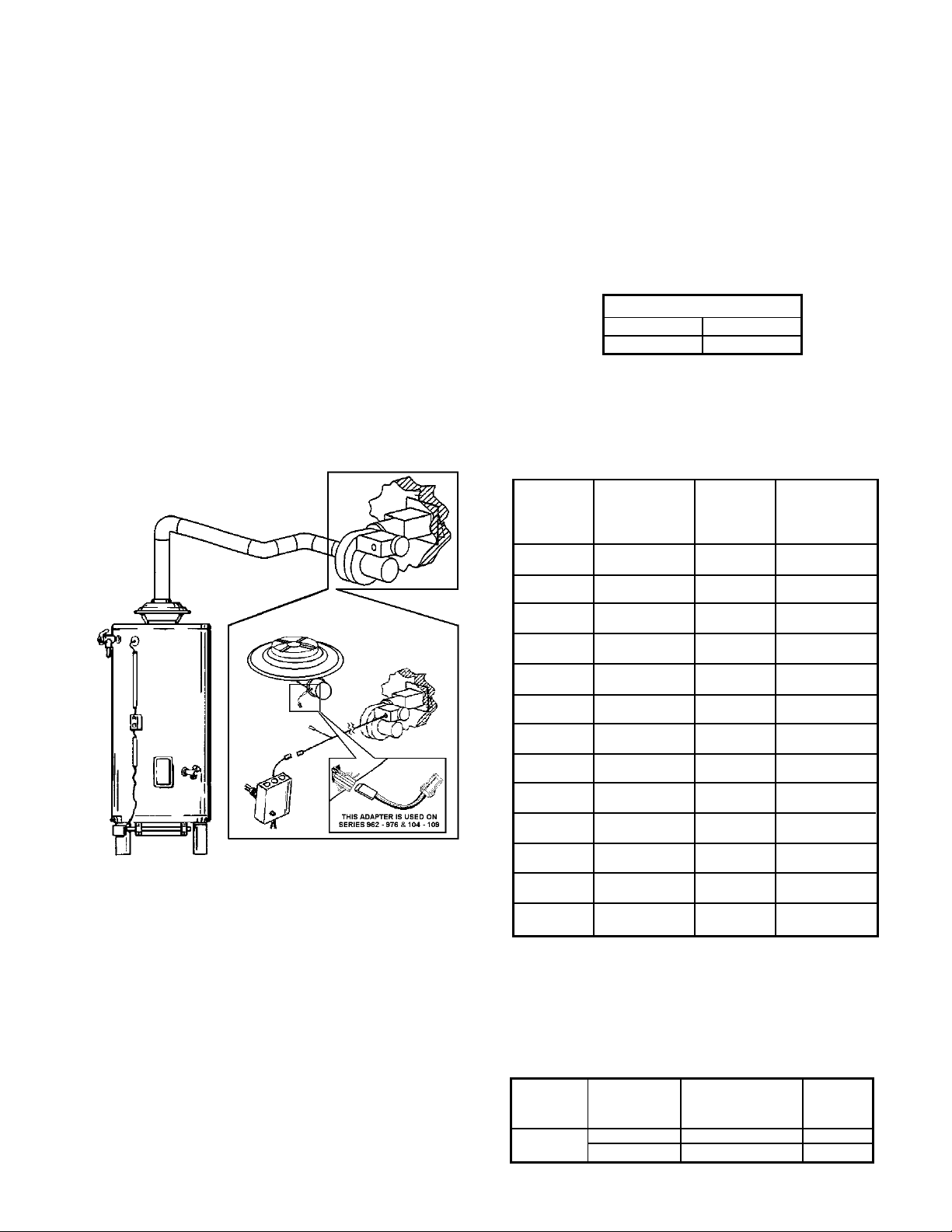

MECHANICAL VENTING

SINGLE UNIT INSTALLATION

When mechanical venting of these heaters is desired, the

following kits are available.

BTR(C) 120 through the BTR(C) 200/A

A. O. Smith part number 193933

BTR(C) 250/A through the BTR(C) 500/A

A. O. Smith part number 193933-1

Where an approved power venter is to be installed to operate in

conjunction with the water heater thermostat, the following codes

must be adhered to. Field wiring should conform to the latest

version of the National Electric Code ANSI/NFPA No. 70. For

Canadian installations the electrical connections and grounding

shall be done in accordance with the current Canadian Electrical

Code CSA C22.1 Part 1 and/or local codes.

NOTE: The power venter must be installed downstream of the

drafthood. See figure 14.

FIGURE 14

VENT INSTALLATION

Seal all joints between the power venter and the vent termination.

This is to prevent leakage of exhaust products into the room(s)

due to positive pressure of blower.

The "Sequence of Operation" description will be the same with

mechanical venting except,

When the appliance thermostat calls for heat:

Thermostat contacts "Close" and the power venter blower

(120 VAC) is energized. Sufficient draft must be established for

the "Draft Prover Switch (N.O.)" to "Close". When the draft prover

switch "Closes" the relay coil of the flue damper is energized.

See side wall vent kit installation manual for complete

instructions.

MULTIPLE UNIT INSTALLATIONS

For multiple unit installations, contact A.O. Smith Water Products

Company, Technical Support Center at 1-800-527-1953. In

Canada, contact A.O. Smith Enterprises, Ltd. at 1-800-265-8520.

TABLE 5

MANIFOLD GAS PRESSURE IN INCHES

OF WATER COLUMN (ALL MODELS*)

TYPE OF GAS

NATURAL PROPANE

3.5 10.0

Gas pressure specified in Table 5, refer to flow pressure taken

at pressure tap of automatic gas valve while heater is operating.

TABLE 6

APPROXIMATE TIME REQUIRED TO CONSUME

1 CU. FT. OF GAS AT FULL CAPACITY

INPUT TYPE BTUH TIME REQ’D

RATE OF PER TO CONSUME

(BTUH) GAS CU. FT. 1 CU. FT.

OF GAS

120,000 NATURAL 1050 31.5 SEC.

PROPANE 2500 75.0 SEC.

154,000 NATURAL 1050 24.5 SEC.

PROPANE 2500 58.4 SEC.

180,000 NATURAL 1050 21.1 SEC.

PROPANE 2500 50.3 SEC.

190,000 NATURAL 1050 19.9 SEC.

PROPANE 2500 47.4 SEC.

199,000 NATURAL 1050 19.0 SEC.

PROPANE 2500 47.4 SEC.

250,000 NATURAL 1050 15.1 SEC.

PROPANE 2500 35.3 SEC.

251,000 NATURAL 1050 15.06 SEC.

PROPANE 2500 35.1 SEC.

275,000 NATURAL 1050 13.75 SEC.

PROPANE 2500 32.2 SEC.

305,000 NATURAL 1050 12.4 SEC.

PROPANE 2500 29.5 SEC.

360,000 NATURAL 1050 11.4 SEC.

PROPANE 2500 24.0 SEC.

365,000 NATURAL 1050 10.4 SEC.

PROPANE 2500 24.7 SEC.

399,000 NATURAL 1050 9.5 SEC.

PROPANE 2500 22.6 SEC.

500,000 NATURAL 1050 7.6 SEC.

PROPANE 2500 18.0 SEC.

Figures shown are valid for 0-2000 ft.(0-610m) installations.

See “HIGH ALTITUDE INSTALLATIONS” for deration

requirements over 2000 ft.(610m)

TABLE 7

PILOT BURNER INFORMATION

TYPE OF PILOT BURNER RATED

MODEL GAS PART NUMBER ORIFICE

(WITH ORIFICE) SIZE

ALL NATURAL 193314-0 0.018

MODELS PROPANE 193314-1 0.014

Loading ...

Loading ...

Loading ...