Loading ...

Loading ...

Loading ...

PRESSUREWASHERMAINTENANCE

CleanDebris

Daily or before use, clean accumulated debris from pressure

washer. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

Inspect cooling air slots and openings on the pressure

washer. These openings must be kept clean and

unobstructed.

Pressurewasher parts should be kept clean to reduce the

risk of overheating and ignition of accumulated debris.

* Usea damp cloth to wipe exterior surfaces clean.

NOTICE Improper treatment of pressure washer can

damage it and shorten its life.

• DONOTinsertany objectsthroughcoolingslots.

A WAFtNIN(_ The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leading to serious

injury and possible amputation.

Spray gun traps high water pressure, even when engine is

stopped and water is disconnected, which can cause

injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

• ALWAYSpointspraygunin safedirection,pressredbutton

andsqueezesprayguntriggerto releasehighpressure,every

timeyoustopengine.

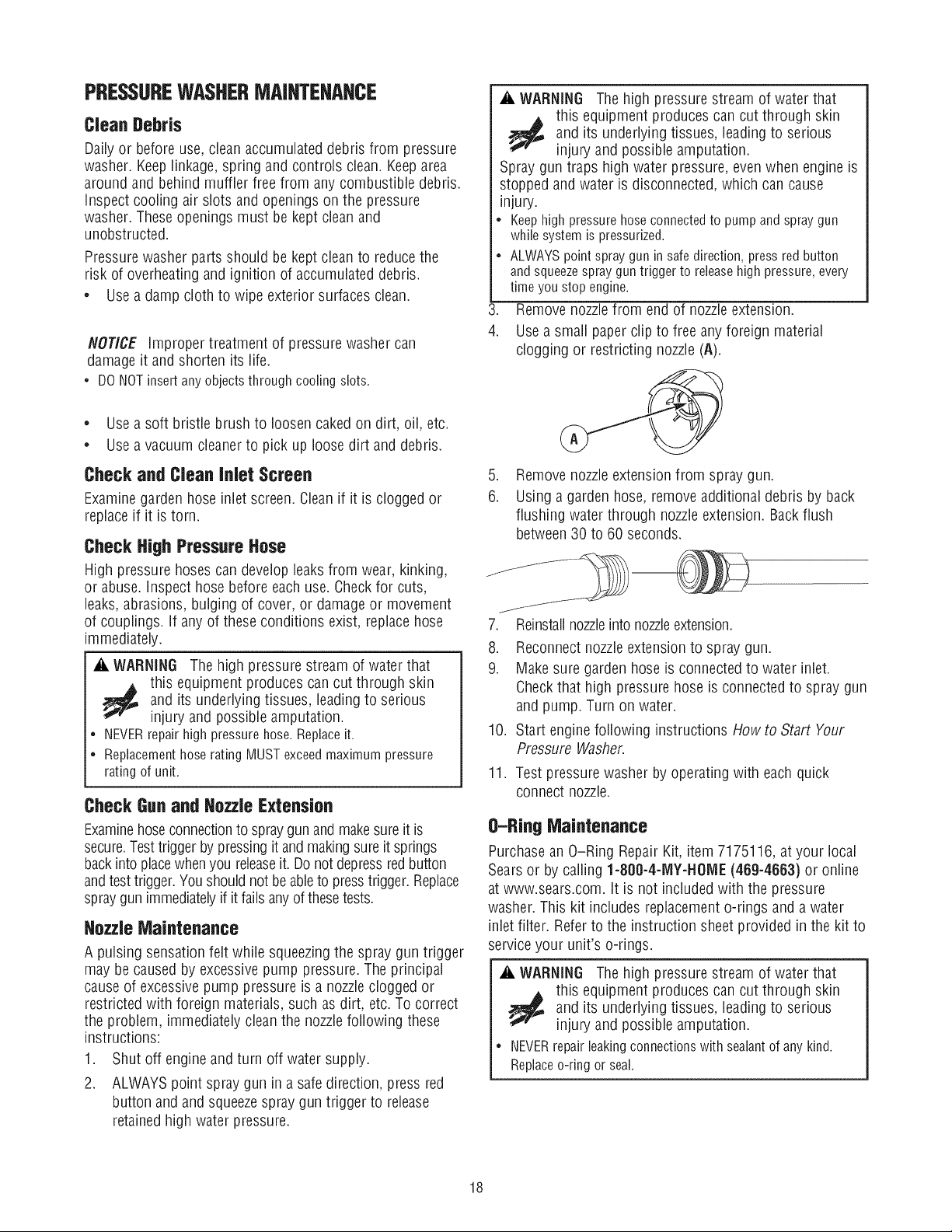

3. Remove nozzlefrom end of nozzleextension.

4. Usea small paperclip to free any foreign material

clogging or restricting nozzle (A).

* Usea soft bristle brush to loosen caked on dirt, oil, etc.

* Usea vacuum cleaner to pick up loose dirt and debris.

Checkand Clean inlet Screen

Examinegarden hose inlet screen. Cleanif it is clogged or

replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear, kinking,

or abuse, inspect hose before each use. Checkfor cuts,

leaks, abrasions, bulging of cover, or damageor movement

of couplings. If any of these conditions exist, replace hose

immediately.

A WARNING The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leadingto serious

injury and possible amputation.

• NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

Check Gun and Nozzle Extension

Examinehoseconnectionto spraygun and makesure it is

secure.Testtrigger by pressingit and makingsure it springs

backinto placewhenyou releaseit. Do not depressredbutton

andtest trigger.Youshould not beableto presstrigger. Replace

spraygun immediatelyif it fails anyof thesetests.

Nozzle Maintenance

A pulsing sensation felt while squeezingthe spray gun trigger

may be caused by excessive pump pressure. The principal

causeof excessive pump pressure is a nozzleclogged or

restricted with foreign materials, such as dirt, etc. To correct

the problem, immediately clean the nozzle following these

instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction, press red

button and and squeezespray gun trigger to release

retained high water pressure.

5. Remove nozzleextension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzleextension. Back flush

between30 to 60 seconds.

7. Reinstallnozzleinto nozzleextension.

8. Reconnect nozzleextension to spray gun.

9. Makesure garden hose is connected to water inlet.

Checkthat high pressure hose is connected to spray gun

and pump. Turn on water.

10. Start engine following instructions How to Start Your

Pressure Washer.

11. Test pressure washer by operating with each quick

connect nozzle.

O-Ring Maintenance

Purchasean O-Ring Repair Kit, item 7175116, at your local

Searsor by calling 1-800-4-MY-NOME (469-4663) or online

at www.sears.com. It is not included with the pressure

washer. This kit includes replacemento-rings and a water

inlet filter. Refer to the instruction sheet provided in the kit to

service your unit's o-rings.

A WARNING The high pressure stream of water that

this equipment produces can cut through skin

and its underlying tissues, leading to serious

injury and possible amputation.

• NEVERrepairleakingconnectionswithsealantof any kind.

Replaceo-ring or seal.

18

Loading ...

Loading ...

Loading ...