Loading ...

Loading ...

Loading ...

Part number 550-100-325/0419

83

AquaBalance

®

Series 2 Wall Mount Gas-fired Water Boiler – Boiler Manual

At Minimum Rate:

1. Remove T-40 cap, see Figure 108, page 82, for Offset screw

adjustment. Adjust the boiler to minimum output and allow

the boiler to stabilize.

2. Now adjust the offset pressure setting (Figure 109 - screw B)

Torx (T-40 male driver) until the CO

2

is at the correct SET-

TING LEVEL (see Figure 110), confirm that the CO/CO

2

ratio is within limits (clockwise to increase gas).

33 Startup — nal checks

(continued)

Re-check the Maximum and Minimum

Rate

3. After the gas valve is adjusted, please check one more

time that the Maximum and Minimum rate CO/CO

2

to ensure that the values have not changed.

4. In the event that the CO

2

setting level with an acceptable

CO/CO

2

ratio cannot be obtained please contact your

Weil-McLain Technical Support.

❏

1. Operate the boiler on HIGH fire.

2. A leak would appear as vapor on the surface of the

mirror.

3. If there is any indication of a leak at any joint, immedi-

ately shut down the boiler.

a. If possible, tighten the retaining screws or nuts

(without over-tightening).

b. If this does not correct the problem, disassemble

the components where the leak appeared. Use the

procedures given in the Maintenance section of

this manual.

c. When disassembling components, inspect gaskets to

see if there is damage. Replace any damaged gasket.

d. Contact your Weil-McLain Technical Support if the

problem cannot be addressed with the information

provided in this manual.

❏

1. After the boiler has been installed, turn off the boiler.

2. Shut off the manual gas valve located on the gas line to

cut flow of fuel to the boiler.

3. Turn on the boiler. It will start to ignite and a “d3” code

will flash. After the “d3” code flash for some time the

boiler will go into a Lockout condition and a “A01” code

will show in the display. It means that the boiler tried to

ignite without success (code “d3”) for three (3) times

and when into Lockout mode(code “A01”). This means

that the ignition system safety device worked properly.

4. Open the manual gas valve located on the gas line to

resume fuel supply to the boiler.

5. Hit the “” button once to Clear the Lockout code

“A01”.

Figure 110Minimum rate combustion values –

measured values must be within the ranges

given below

Adjust in steps of no more than 1/8 of a turn and

wait 1 minute after each adjustment to allow the

setting to stabilize. Turning the screw too far will

cause the adjustment to reverse behavior.

Combustion Range

Boiler Model

CO/(PPM) CO

2

NG % CO

2

LP %

AB-80

20

AB-120

20

AB-155

7

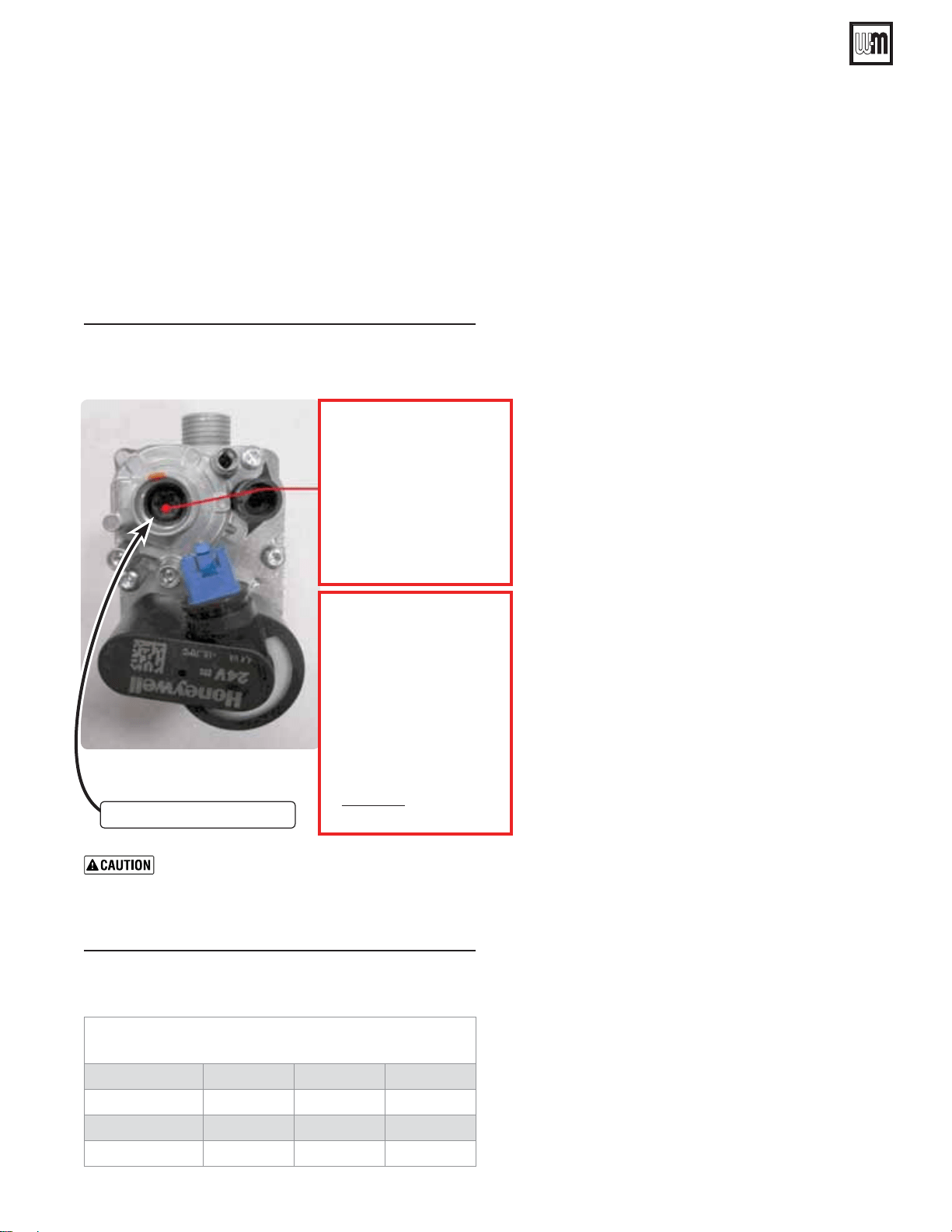

Figure 109Offset

Offset Regulating screw

Test at MIN. Power 00%

Turn clockwise (open gas)

for “MA gas ow”

Turn counter-clockwise

(close gas)

for “MIN gas ow”

Rough start point

For LP Start up ONLY

Adjust gas valve

LOW FIRE

screw on left with

Allen wrench

turn

Counter-Clock wise

- turn.

Final Combustion values

MUST BE checked with

Combustion Analyzer.

B

Loading ...

Loading ...

Loading ...