Loading ...

Loading ...

Loading ...

PREPARATION

• Remove all tape and packaging,, Lift up the cooktop

(on models with standard twin burners) and remove

any packing material under it, Make sure the standard

twin burners are properly seated and IeveL

° Remove plastic film that covers some chrome parts

(around oven door, side trim).

- Take the accessory pack out of the oven.

• Check to be sure that no range parts have come

loose during shipping.

STEP 1

Provide Adequate Gas Supply

Your range is designed to operate at a pressure of

4" (10.2 cm) of water column on natural gas or, if

designed for LP gas (propane or butane), 10" (25.4 cm)

of water column, Make sure you are supplying your

range with the type of gas for which it is designed

This range is convertible for use on natural or propane

gas. If you decide to use this range on LP gas,

conversion must be made by a qualified LP installer

before attempting to operate the range on that gas.

For proper operation, the pressure of natural gas

supplied to the regulator must be between 4" (10.2 cm)

and I3" (33 cm) of water column. For LP gas, the

pressure supplied must be between 10" (25.4 cm) and

13" (33 cm) of water column°

When checking for proper operation of the regulator, the

inlet pressure must be at feast 1" (2.5 cm) greater than

the operating (manifold) pressure as given above. The

pressure regulator located at the in_etof the range

manifold must remain in the supply line regardless of

whether natural or LP gas is being used.

A flexible metal appliance connector used to connect the

range to the gas supply line should have an IoD. of 1/2"

and be 5 feet (1_5m) in length for ease of installation In

Canada, flexible connectors must be single wall metal

connectors no longer than 6 feet (1,8 m) in length,

STEP 2

Connect the Range to Gas

Shut off the main gas supply valve before disconnecting

the old range and leave it off until new hook-up has

been completed_ Don't forget to relight the pilot on other

gas appliances when you turn the gas back on,

Because hard piping restricts movement of the range,

the use of an A,GA,-certified flexible metal appliance

connector is recommended unless local codes require

a hard-piped connection_ Never use an old connector

when installing a new range° If the hard piping method

is used, you must carefully align the pipe; the range

cannot be moved after the connection is made.

To prevent gas leaks, use pipe joint compound or wrap

Teflon* pipe thread tape around all male (external)

pipe threads.

*Teflon: Registered trademark of DuPont

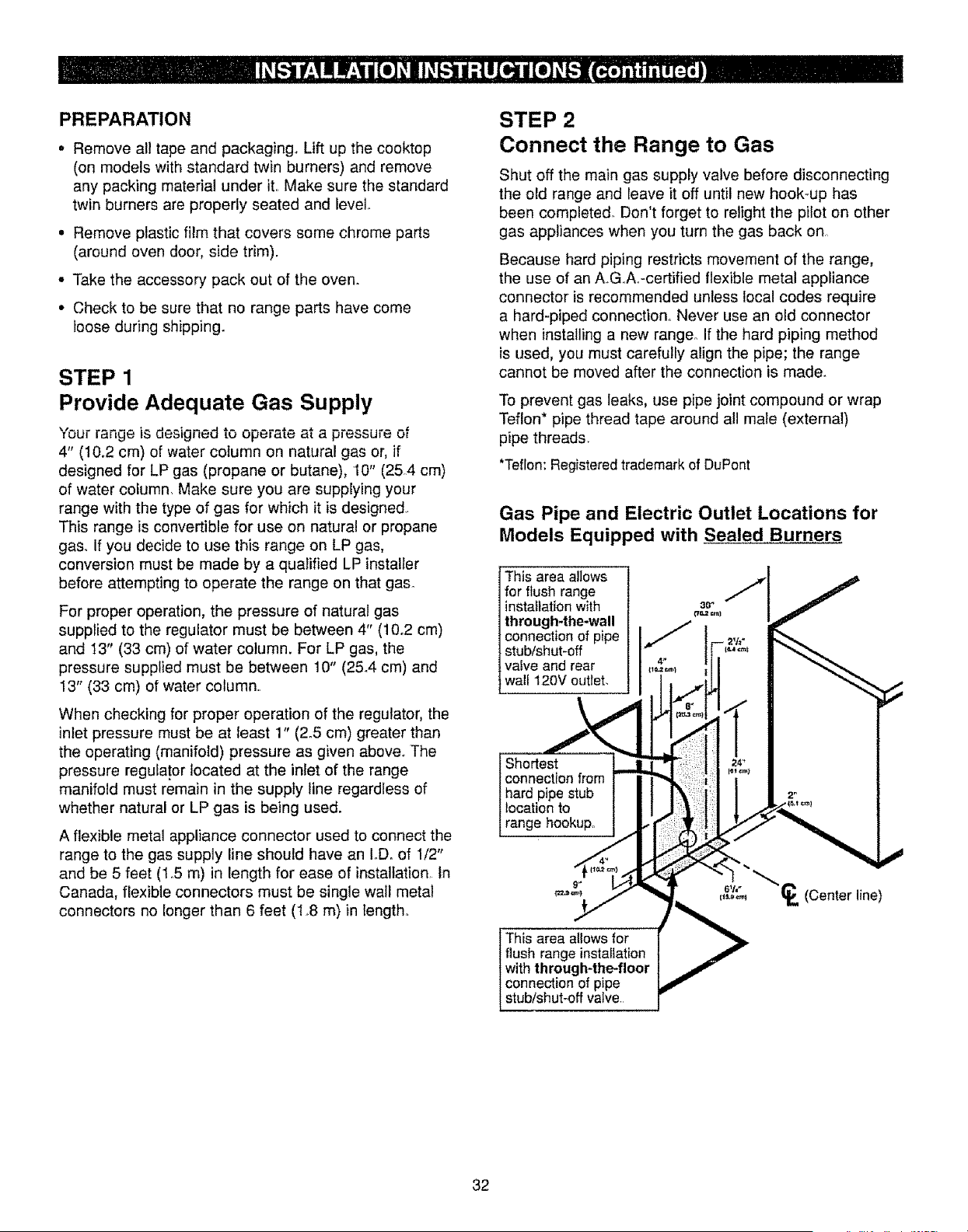

Gas Pipe and Electric Outlet Locations for

Models Equipped with Sealed Burners

This area allows

for flush range

installation with

thro ugh-the-wall

connection of pipe

stub/shut-off

valve and rear

wall 120V outlet,

Shortest

connection from

hard pipe stub

location to

range hookup

30"

I This area allows for

flush range installation

with through-the-floor

connection of pipe

stub/shut-off valve

32

Loading ...

Loading ...

Loading ...