Loading ...

Loading ...

Loading ...

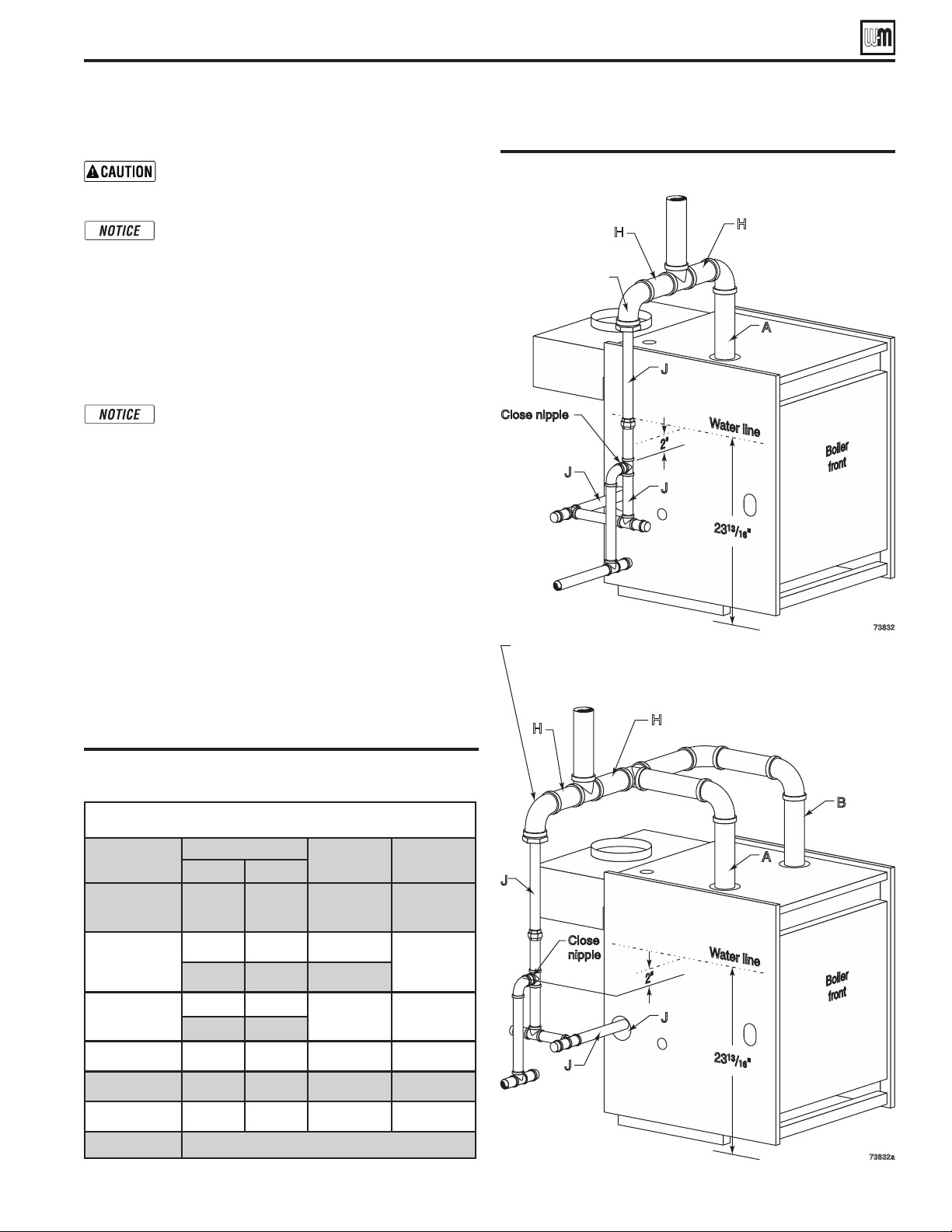

H

H

A

J

J

J

Water line

Close nipple

Reducing elbow or

elbow with bushing

Condensate return

23 / "

13

16

2"

Boiler

front

Steam to system

73832

EG/PEG

H

H

A

J

J

J

Water line

Close

nipple

Reducing elbow or

elbow with bushing

Condensate

return

23 / "

13

16

2"

Boiler

front

Steam to

system

73832a

Install offset header

to prevent bending

at section tappings

EGH

B

Part Number 550-142-905/0319

17

General

Failure to properly pipe the boiler may result in

improper operation and damage to the boiler or

building.

Steam supply must be on same end as controls.

Return may be from either end.

1. Install the boiler jacket before connecting return piping. (Sup-

ply piping can be connected before or after jacket installation.)

Connect controls after all piping is connected.

2. See Table 7 for recommended pipe sizing.

3. See Figure 5, page 10, for tapping locations.

4. EGH only - install 3/4” system blow-off (drain) valve in lowest

part of return piping close to boiler.

Condensate return —

• Satisfactoryoperationofasteamheatingsystemdepends

on adequate condensate return to boiler to maintain a

steady water level.

• Avoidaddingrawmakeupwater.

• Wherecondensatereturnisnotadequate,installlowwater

cutoff/pump control, condensate receiver and condensate

boiler feed pump. Refer to Table 5, page 16, for sizing.

Connecting to parallel-flow piping

1. See Figure 18 for parallel-flow steam systems.

Connecting to counterflow piping

Whenconnectingtoacounterowsystem,theboilersteamsupply

must connect into the top of the counterflow system header, as

shown in Figure 19, page 18.

Figure 18 Recommended piping for parallel-flow systems

Table 7 Recommended steam boiler pipe sizing

Steam Boiler Piping Minimum Recommended Pipe Sizes

Boiler Model

Riser Pipe Size

Header *

H

Equalizer

J

A B

EG-30, 35

PEG-30, 35

2” –– 2” 1 ½”

EG-40, 45, 50

PEG-40, 45, 50

2 ½” –– 2 ½”

1 ½”

2” 2” 2 ½”

EG-55, 65, 75

PEG-55, 65

2” 2”

3” 1 ½”

3” ––

EGH-85, 95

2” 2” 3” 1 ½”

EGH-105

2 ½” 2 ½” 3” 1 ½”

EGH-115, 125

2 ½” 2 ½” 4” 1 ½”

*

24” minimum from waterline to bottom of header.

Connect piping – steam boilers (continued)

EG

&

PEG sEriEs 5

•

EGH sEriEs 5 Gas-firEd boilErs — boilEr manual

Loading ...

Loading ...

Loading ...