Loading ...

Loading ...

Loading ...

EN-4 452234.66.02 · FD 9311 www.dimplex.de

English

SI 50TE - SI 130TE

4 Accessories

4.1 Connecting Flanges

The use of flat-sealing connecting flanges allows the unit, as an

option, to be connected by means of flanges.

4.2 Remote control

A remote control adds convenience and is available as a special

accessory. Operation and menu navigation are identical to those

of the heat pump manager. Connection takes place via an inter-

face (special accessories) with RJ 12 Western plug.

NOTE

In the case of heating controllers with a removable operating element,

this can also be used directly as a remote control.

4.3 Building management

technology

The heat pump manager can be connected to a building man-

agement system network via supplementation of the relevant in-

terface plug-in card. The supplementary installation instructions

of the interface card must be consulted regarding the exact con-

nection and parameterisation of the interface.

The following network connections can be made on the heat

pump manager:

Modbus

EIB, KNX

Ethernet

ATTENTION!

If the heat pump or circulating pumps are controlled externally, an flow

rate switch is required to prevent the compressor from being switched on

when there is no volume flow.

4.4 Thermal energy meter WMZ

4.4.1 General description

The thermal energy meter (WMZ 25/32) is used for measuring

the quantity of thermal energy supplied. It is available as an ac-

cessory. Due to the additional heat exchanger, two thermal en-

ergy meters are required for measuring the quantity of thermal

energy.

Sensors in the flow and return of the heat exchanger pipes and

an electronics module acquire the measured values and transmit

a signal to the heat pump manager, which, depending on the cur-

rent operating mode of the heat pump (heating/DHW/swimming

pool), totals the thermal energy in kWh and displays them in the

operating data and history menu.

NOTE

The thermal energy meter complies with the quality requirements of the

German market incentive programme subsidising efficient heat pumps.

The thermal energy meter is not subject to obligatory calibration, and can

thus not be used for the heating cost billing procedure!

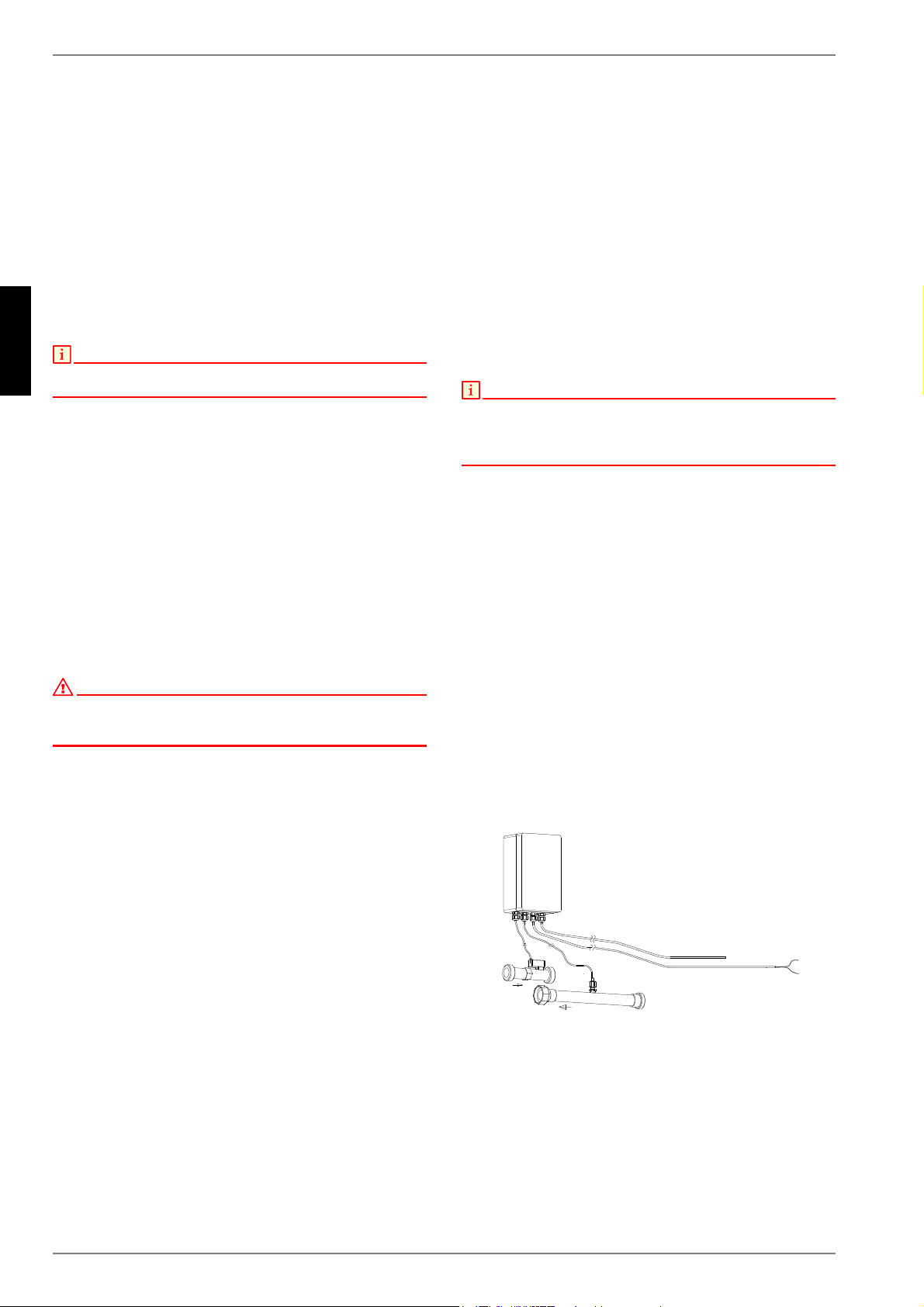

4.4.2 Hydraulic and electrical

integration of the thermal

energy meter

The thermal energy meter requires two measuring devices for

data acquisition.

A measuring tube for the flow measurement

This must be installed in the heat pump flow (observe flow

direction).

A temperature sensor (copper pipe with immersion sleeve)

This must be installed in the heat pump return.

The installation locations for both measuring tubes should be as

close to the heat pump as possible in the generator circuit.

The distance from pumps, valves and other installations must be

taken into account, as eddying effects could lead to incorrect

thermal energy metering (a calming section of 50 cm is recom-

mended).

/13(

9+]

1,'

*9$&

7KHUPDOHQHUJ\PHWHUFDVLQJHOHFWURQLFV

LQWKHKHDWLQJIORZ

LQWKHKHDWLQJUHWXUQIORZ

3XOVHWKHUPDOHQHUJ\PHWHU

Loading ...

Loading ...

Loading ...