Loading ...

Loading ...

Loading ...

8

installation manual

2

Bend the tubing in proper way. Do not harm to them.

Connect the indoor unit at first, then the outdoor

unit.

Too large torque will harm the bellmouthing and too small

will cause leakage. Please determine the torque

according to Table 4.

After the connecting work is finished, be sure to check

that there is no gas leak.

The bending angle should not exceed 90.

Bending position is preferably in the middle of the

bendable pipe. The larger the bending radius the better it

is.

Do not bend the pipe more than three times.

When connecting the flare nut, coat the flare both inside

and outside with either oil or ester oil and initially tighten

by hand 3 or 4 turns before tighting firmly.

Bend the pipe with thumb

min-radius 100mm

How to expel the air with a vacuum pump

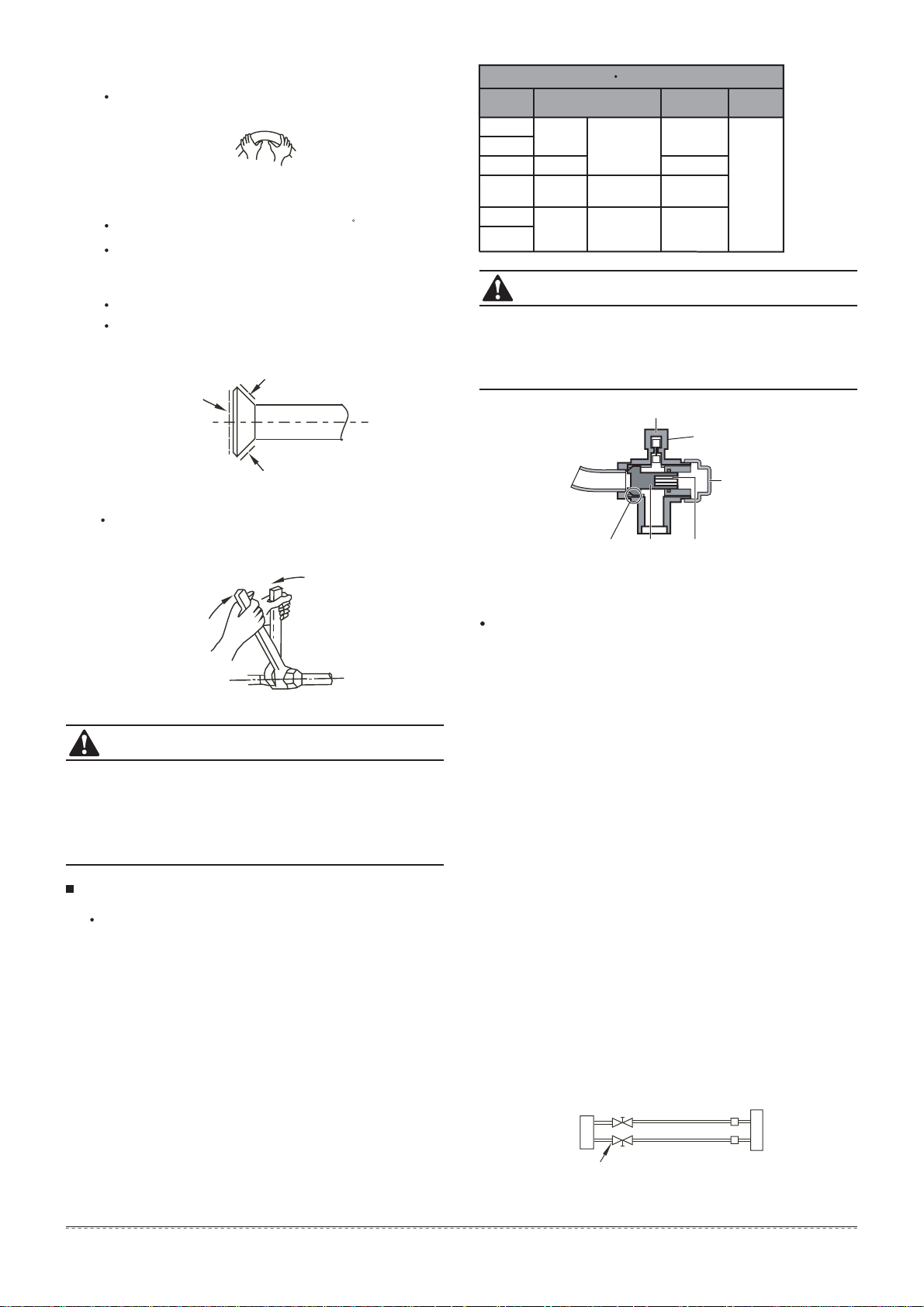

Stop valve operation introduction

1. Opening stop valve

1.

2.

3.

Remove the cap and turn the valve counter

clock-wise with the hexagon wrench.

Turn it until the shaft stops.Do not apply excessive force

to the stop valve. Doing so may break the valve body,

as the valve is not a backseat type. Always use the

special tool.

Make sure to tighten the cap securely.

Fig.7-6

Fig.7-7

Fig.7-8

Be sure to use both a spanner and torque wrench

together when connecting or disconnecting pipes to /from

the unit.

Make sure to tighten the cap securely.

For the tightening torque,refer to the table below.

2. Closing stop valve

1.

2.

Remove the cap and turn the valve clockwise with the

hexagon wrench.

Securely tighten the valve until the shaft contacts the

main bodyseal.

CAUTION

CAUTION

Always use a charge hose for service port connection.

After tightening the cap, check that no refrigerant leaks

arepresent.

Table 7-3

Tightening torque N M (Turn clockwise to close)

Stop

Valve size Shaft (valve body)

Cap

(Valve lid)

Ø6.35

Hexagonal

wrench 4 mm

Ø9.52

Ø12.7

Ø15.9

Hexagonal

wrench 6 mm

Ø22.2 Hexagonal

wrench

10 mm

Ø25.4

Maintenance

nut

36~44

23~27

18~22

13.5~16.5

5.4~6.6

8.1~9.9

13.5~16.5

27~33

11.5~13.9

1

2

4

3

5

7

6

Using the vacuum pump

Loosen and remove the maintenance nuts of stop valves A

and B, and connect the charge hose of the manifold valve to

the service port of stop valve A. (Be sure that stop valves A

and B are both closed)

Connect the joint of the charge hose with the vacuum pump.

Open the Lo-lever of the manifold value completely.

Turn on the vacuum pump. At the beginning of pumping,

loosen the maintenance nut of stop valve B a little to check

whether the air comes in (the sound of the pump changes,

and the indicator of compound meter turns below zero). Then

fasten the maintenace nut.

When the pumping has finished, close the Lo-lever of the

manifold valve completely and turn off the vacuum

pump.Make pumping for 15 minutes or more and check that

the compound meter indicates -76cmHg(-1X10 Pa)

Loosen and remove the cap of stop valves A and B to open

stop valve A and B completely, then fasten the cap.

Disassemble the charge hose from the service port of stop

valve A, and fasten the nut.

5

Fig.7-10

Fig.7-9

service port

cap

maintenance nut

Stop valve

Gas side

Liquid side

hexagon holeshaftseal

Outdoor

unit

Indoor

unit

A

C

D

B

Loading ...

Loading ...

Loading ...