Loading ...

Loading ...

Loading ...

4

GB

Prior to installation, ensure that the local distribution

conditions (nature of the gas and gas pressure)

and the adjustment conditions are compatible. The

adjustment conditions for this appliance are stated on

the data badge which is fitted on the back panel.

This appliance is not designed to be connected to a

combustion products evacuation device. It must be

installed and connected in accordance with current

installation regulations. particular attention should

be given to the relevant requirements regarding

ventilation.

MODEL NUMBERS ID60G1; ID60G2

Category II2H3+ (GB)

These models are set to burn NATURAL GAS (G20)

at 20 mbar but can be converted for use on BUTANE

(G30) at 28-30mbar or PROPANE (G31) at 37mbar with

the use of the LPG conversion kit that can be obtained

free of charge, if you contact our Genuine Parts and

Accessories department (see Key Contacts, back

page).

GAS SAFETY (INSTALLATION & USE)

REGULATIONS

It is the law that all gas appliances are installed by

competent persons in accordance with the current

edition of the above regulations. It is in your interest

and that of safety to ensure compliance with the

law. In the UK,gas safe registered installers work to

safe standards of practice. The cooker must also be

installed in accordance with BS 6172. Failure to install

the cooker correctly could invalidate the warranty

liability claims and could lead to prosecution.

LOCATION

The cooker may be located in a kitchen, kitchen/diner

Installation

or a bed-sitting room, but not in a room containing a

bath or shower. The cooker must not be installed in a

bed-sitting room of less than 20m

3

.

When adjusted for use on Butane (G30) or Propane

(G31), the cooker must not be installed in a room or

internal space below ground level, e.g. in a basement.

PROVISION FOR VENTILATION

The room containing the cooker should have an air

supply in accordance with BS 5440: Part 2.

The room must have an opening window or equivalent;

some rooms may also require a permanent vent. If the

room has a volume between 5 and 10m

3

, it will require

an air vent of 50cm

2

effective area unless it has a

door which opens directly to outside. If the room has

a volume of less than 5m

3

, it will require an air vent of

100cm

2

effective area. If there are other fuel burning

appliances in the same room, BS 5440: Part 2 should

be consulted to determine air vent requirements.

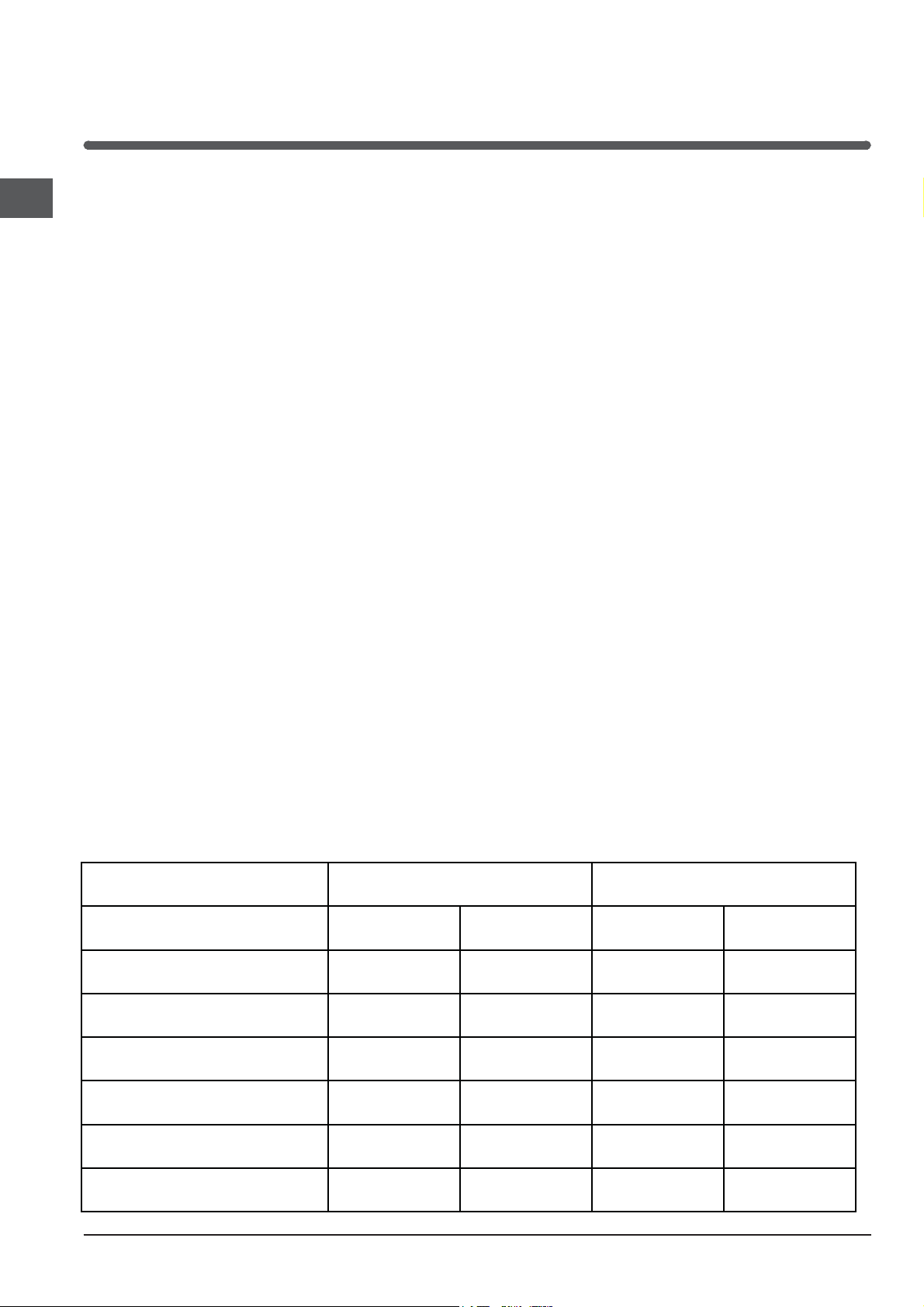

TECHNICAL DATA

Gas connection Rp ½ (½” BSP female)

Pressure test point Front left hotplate

injector

Gas rate adjustment None

Aeration adjustment None

Electrical connection Flexible cord fitted with a

3 pin 13 amp plug

230/240V a.c. 50x60

Hz.

13A fuse.

G20 at 20mbar

G30 at 28-30mbar

G31 at 37mbar

Burner

Heat Input Injector Heat Input Injector

Hotplate

Front Left

3.0 kW 116 3.0 kW (218g/h) 86

Hotplate

Rear Left and Rear Right

2.0 kW 103 2.0 kW (145g/h) 70

Hotplate

Front Right

1.1 kW 79 1.0 kW (73g/h) 50

Grill 3.7 kW 150 (X) 3.4 kW (243g/h) 91

Main Oven 2.5 kW 115 2.3 kW (167g/h) 71

Top Oven 1.9 kW 100 1.9 kW (138g/h) 66

Loading ...

Loading ...

Loading ...