Loading ...

Loading ...

Loading ...

7COOKER HOOD INSTALLATION

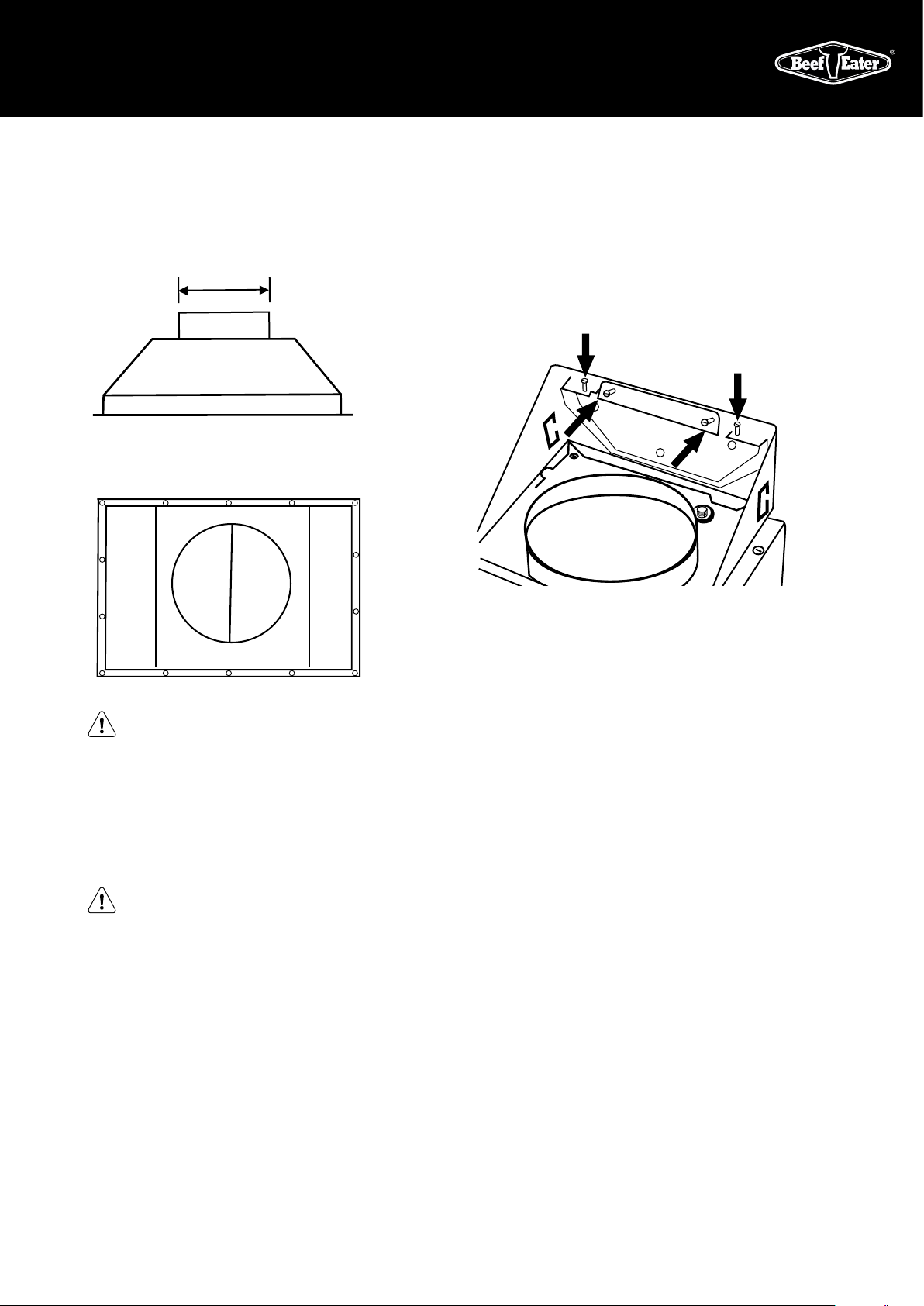

4. If required, fix the exhaust transition duct using the

screws supplied, prior to installing the cooker hood

into position (Fig.D).

Transition piece

200

Transition piece

Screw holes (14 places)

200

WARNING!

Use screws provided to secure transition piece at

preformed holes. Using alternate screws and hole

locations may cause an electrical safety risk.

5. Hang hood on the mounting bracket. The rangehood

should sit squarely onto the wall brasket.

The two top holes of the bracket are to lock the

rangehood into position once it is in place.

WARNING!

Due to product weight, take appropriate measures to lift

and position the product to avoid injury.

6. Make fine adjustments and lock the rangehood

into position

Use the vertical screws on the rangehood to make

fine adjustments to the rangehood to ensure that the

rangehoods is perfect horizontal.

Screw the two horizontal screws in the wall bracket

all the way in to secure the rangehood and ensure it

cannot be accidentally dislodged.

200

7. Non-combustible rigid on flexible flue pipe is to be used

for exhausting the hood.

Use worm drive clamps, cable ties or suitable duct tape to

secure flexible pipe to the transition duct.

NOTE: We recommend extending flue pipe through the roof

to external roof cowl to vent exhaust externally.

We do not recommend venting into ceiling cavity.

To ensure optimum performance of the cooker hood, the

use of 2 x 150mm or 1 x 200 mm diameter rigid ducting is

recommended. The use of bends should be avoided.

Rigid flexible ducting is suitable, although loose flexible

ducting is unacceptable. All ducting must be fire retardant.

Electrical connection

Check that the installation complies with the standards

of local building, gas and electrical authorities. Before

connecting to the mains supply ensure that the mains

voltage corresponds to the voltage on the rating plate

inside the cooker hood.

COOKER HOOD INSTALLATION

Loading ...

Loading ...

Loading ...