Loading ...

Loading ...

Loading ...

En-5

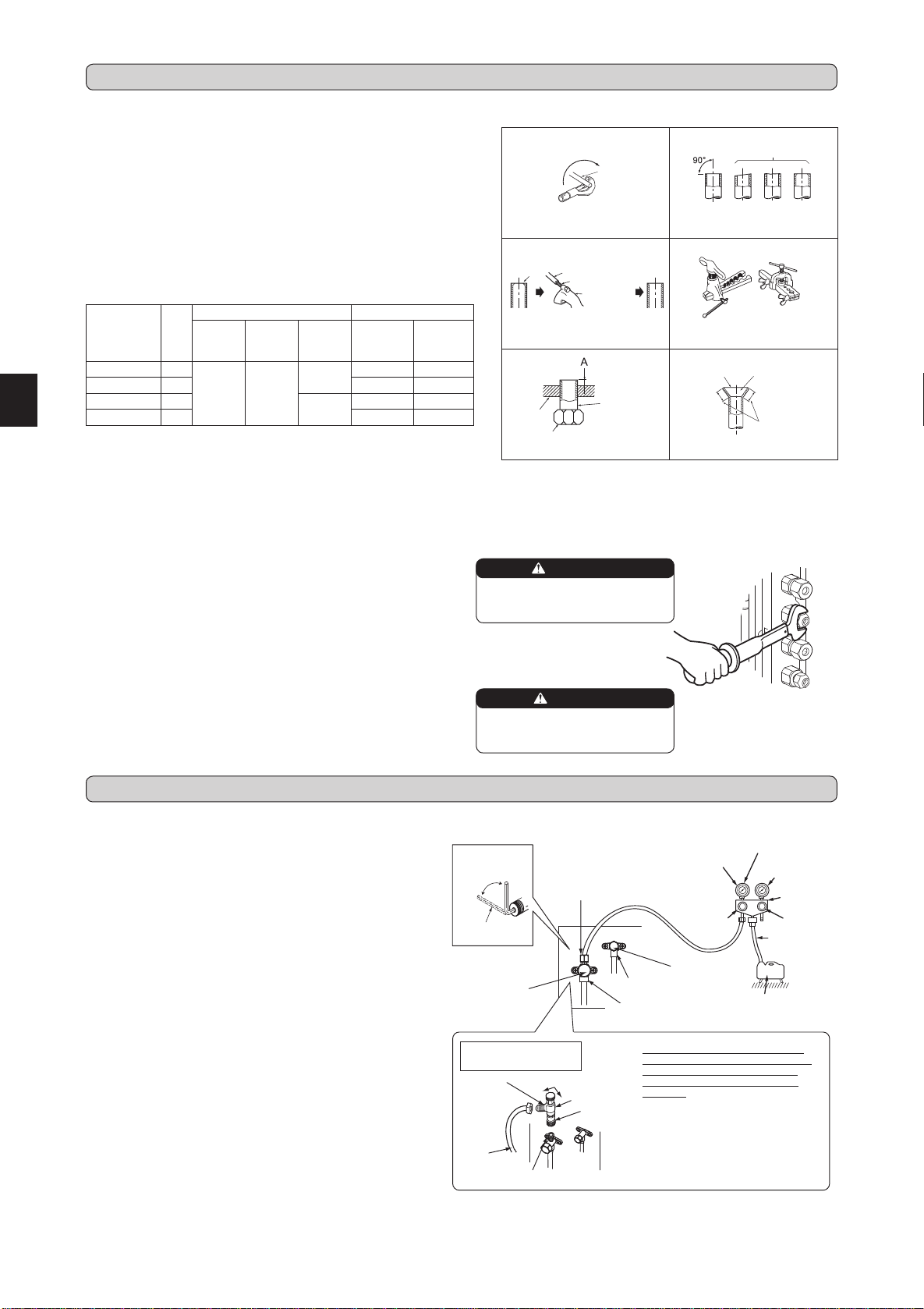

Fig. 1 Fig.2

Fig.3 Fig.4

Fig.5 Fig.6

3-1. FLARING WORK

Pipediameter

(mm)

Nut

(mm)

A(mm) Tighteningtorque

Clutch

typetool

forR410A

Clutch

typetool

forR22

Wing nut

typetool

forR22

N•m kgf•cm

ø6.35(1/4”) 17

0to0.5 1.0to1.5

1.5to2.0

13.7to17.7 140to180

ø9.52(3/8”) 22 34.3to41.2 350to420

ø12.7(1/2”) 26

2.0to2.5

49.0to56.4 500to575

ø15.88(5/8”) 29 73.5to78.4 750to800

TiltedUnevenBurred

Good

No good

Burr

Copperpipe

Sparereamer

Pipecutter

Smooth all

around

Evenlength

all around

Inside is shin-

ingwithoutany

scratches.

Flare nut

Die

Copperpipe

Clutchtype

Flaring tool

Wingnuttype

3-2. PIPE CONNECTION

1)Applyathincoatofrefrigerationoil(G)tothearedendsofthepipes

andthepipeconnectionsoftheoutdoorunit.Donotapplyrefrigeration

oilonscrewthreads.Excessivetighteningtorquewillresultindamage

onthescrew.

2)Alignthecenterofthepipewiththatofthepipeconnectionsoftheoutdoor

unit,thenhandtightenthearenut3to4turns.

3)Tightenthearenutwithatorquewrenchasspeciedinthetable.

• Over-tighteningmaycausedamagetothearenut,resultinginrefriger-

antleakage.

• Besuretowrapinsulationaroundthepiping.Directcontactwiththe

barepipingmayresultinburnsorfrostbite.

3-3. INSULATION AND TAPING

1)Coverpipingjointswithpipecover.

2)Foroutdoorunitside,surelyinsulateeverypipingincludingvalves.

3)Usingpipingtape(E),applytapingstartingfromtheentryofoutdoorunit.

• Stoptheendofpipingtape(E)withtape(withadhesiveagentattached).

• Whenpipinghavetobearrangedthroughaboveceiling,closetorwhere

thetemperatureandhumidityarehigh,windadditionalcommercially

soldinsulationtopreventcondensation.

Copper

pipe

1)Cutthecopperpipecorrectlywithpipecutter.(Fig.1,2)

2)Completelyremoveallburrsfromthecutcrosssectionofpipe.(Fig.3)

• Aimthecopperpipedownwardwhileremovingburrstopreventburrs

fromdroppinginthepipe.

3)Removearenutsattachedtoindoorandoutdoorunits,thenputthem

onpipehavingcompletedburrremoval.(Notpossibletoputthemon

afteraringwork.)

4)Flaringwork(Fig.4,5).Firmlyholdcopperpipeinthedimensionshown

in the table. Select A mm from the table according to the tool selected.

5)Check

• ComparethearedworkwithFig.6.

• Ifareisnotedtobedefective,cutoffthearedsectionanddoaring

workagain.

WARNING

When installing the unit, securely

connect the refrigerant pipes before

starting the compressor.

CAUTION

When there are the ports which are

not used, make sure their nuts are

tightened securely.

4-1. PURGING PROCEDURES AND LEAK TEST

1)Removeserviceportcapofstopvalveonthesideoftheoutdoorunit

gaspipe.(Thestopvalvesarefullyclosedandcoveredincapsintheir

initialstate.)

2)Connectgaugemanifoldvalveandvacuumpumptoserviceportofstop

valveonthegaspipesideoftheoutdoorunit.

3)Runthevacuumpump.(Vacuumizeformorethan15minutes.)

4)Checkthevacuumwithgaugemanifoldvalve,thenclosegaugemanifold

valve,andstopthevacuumpump.

5)Leaveasitisforoneortwominutes.Makesurethepointerofgauge

manifoldvalveremainsinthesameposition.Conrmthatpressuregauge

shows-0.101MPa[Gauge](-760mmHg).

6)Removegaugemanifoldvalvequicklyfromserviceportofstopvalve.

7)Fullyopenallstopvalvesonthegaspipeandtheliquidpipe.Operating

withoutfullyopeninglowerstheperformanceandthiscausestrouble.

8)Referto1-2.,andchargetheprescribedamountofrefrigerantifneeded.

Besuretochargeslowlywithliquidrefrigerant.Otherwise,composition

oftherefrigerantinthesystemmaybechangedandaffectperformance

of the air conditioner.

9)Tightencapofserviceporttoobtaintheinitialstatus.

10

)Leaktest

Stopvalve

forGAS

Gaugemani-

foldvalve(for

R410A)

Compoundpressure

gauge(forR410A)

–0.101MPa

(–760mmHg)

Handle

Low

HandleHigh

Vacuumpump

(forR410A)

Chargehose

(forR410A)

*Close

*Open

Hexagonal

wrench

*4to5turns

Stopvalve

forLIQUID

Pressuregauge

(forR410A)

Precautionswhenus-

ingthecontrolvalve

Whenattachingthecontrolvalve

totheserviceport,valvecoremay

deformorloosenifexcesspres-

sureisapplied.Thismaycause

gasleak.

Serviceport

Chargehose

(forR410A)

Body Close

Open

Controlvalve

A

Whenattachingthecontrolvalveto

theserviceport,makesurethatthe

valvecoreisinclosedposition,and

then tighten partA. Do nottighten

partA orturnthebodywhenvalve

coreisinopenposition.

4. PURGING PROCEDURES, LEAK TEST, AND TEST RUN

Stopvalvecap

(Torque24.4to

30.4N•m,250to

310kgf•cm)

Serviceportcap

(Torque10to12N•m,

100to120kgf•cm)

Serviceportcap

(Torque10to12N•m,

100to120kgf•cm)

Stopvalvecap

(Torque21.5to

27.5N•m,220

to280kgf•cm)

3. FLARING WORK AND PIPE CONNECTION

BH79A274H01_en.indd 5 2016/03/23 10:42:18

Loading ...

Loading ...

Loading ...