Loading ...

Loading ...

Loading ...

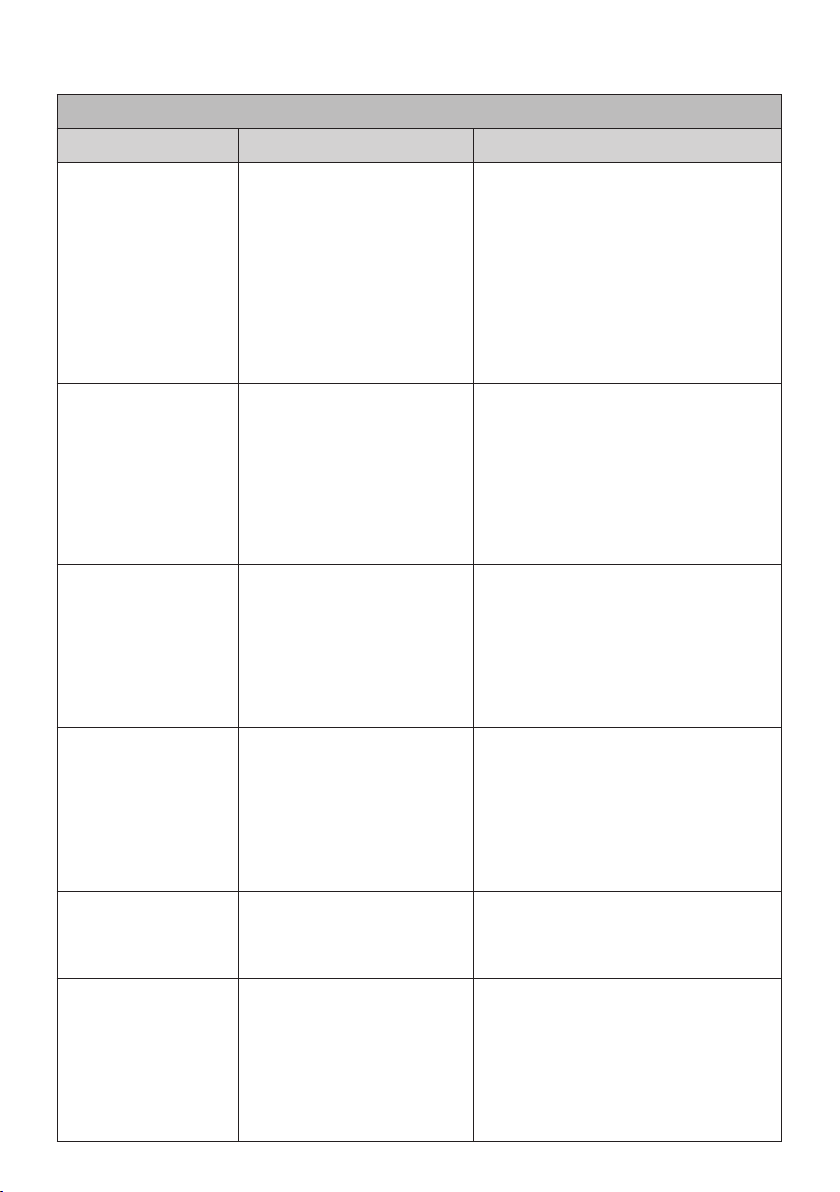

TROUBLESHOOTING

FOOD PROCESSOR

PROBLEM POSSIBLE CAUSE SOLUTION

Food is unevenly

chopped.

Workbowl is overfilled.

You may be running the bowl

continuously instead of using

PULSE.

Food may be cut in random

sizes.

Smaller amounts will process more

evenly.

Use the PULSE button in 5 second

increments or less. Allow the blades to

stop completely before pressing the

PULSE button again.

Cut food in same size pieces before

placing in processor.

Liquid leaks from the

bottom of the

workbowl.

Too much liquid in the

workbowl.

Process smaller amounts.

When processing liquids, do not add

more than 3 cups to workbowl.

Do not remove the blade before

removing workbowl from processor

when processing liquids.

Sliced foods are

uneven and slanted.

The feed chute has not been

well packed or uneven

pressure has been applied to

the food pusher during

processing.

Cut pieces in even lengths, just a little

shorter than the length of the feed

chute.

Pack the chute carefully and\maintain

even pressure on the food pusher as the

food is being processed.

Foods being sliced or

grated fill up on one

side of the bowl.

This is normal. Stop processing occasionally and either,

even out the food in the workbowl or

move it to another bowl.

When food accumulates close to the

disc, empty the workbowl before

continuing.

Some pieces of food

remain on top of the

slice/grate disc.

This is normal. Slice or grate those pieces by hand or

save for another use, like soups that will

be pureed.

Soft cheese collects

on top of the slice/

grate disc.

The cheese was not cold

enough. The pressure exerted

on the pusher was too great.

Be sure soft cheeses are well chilled or

place in freezer until knife inserted into

cheese penetrates about 12mm.

Remember food pusher is to be used as

a guide; never exert hard pressure on

the food pusher.

Loading ...

Loading ...

Loading ...