Loading ...

Loading ...

Loading ...

En-3

1-6. DRAIN PIPING FOR OUTDOOR UNIT

Please perform the drain piping work only when draining from one place.

1) Provide drain piping before indoor and outdoor piping connection.

2) Connect the soft PVC hose (L) I.D.15 mm as shown in the illustration.

3)Makesuretoprovidedrainpipingwithadownhillgradeforeasydrainow.

Note:

Install

the unit horizontally.

Do not use the drain socket (1) in the cold regions. Drain may freeze and it makes

the fan stop.

The outdoor unit produces condensate during the heating operation. Select the in

-

s

tallation place to ensure to prevent the outdoor unit and/or the grounds from being

wet by drain water or damaged by frozen drain water.

(1) Drain socket

(L) Soft PVC hose

2. OUTDOOR UNIT INSTALLATION

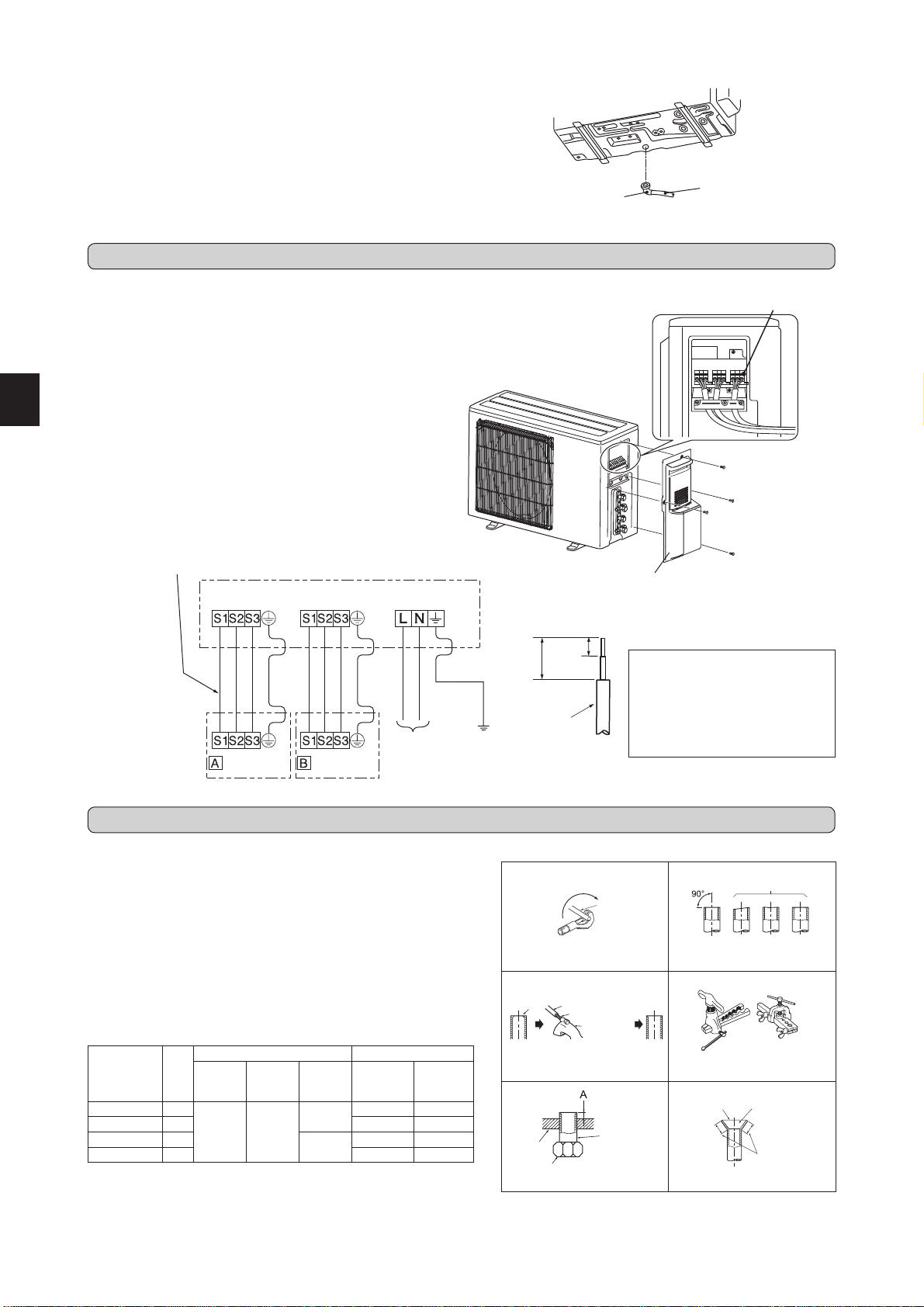

2-1. CONNECTING WIRES FOR OUTDOOR UNIT

• Be sure to attach each screw to its

correspondent terminal when secur-

i

ng the cord and/or the wire to the

terminal block.

• Make earth wire a little longer than

others. (More than 35 mm)

• For future servicing, give extra length

to the connecting wires.

Terminal block for power supply

1) Remove the service panel.

2) Loosen terminal screw, and connect indoor/outdoor unit connecting

wire (B) from the indoor unit correctly on the terminal block. Be careful

not to make mis-wiring. Fix the wire to the terminal block securely so

that no part of its core is appeared, and no external force is conveyed

to the connecting section of the terminal block.

3) Firmly tighten the terminal screws to prevent them from loosening. Af

-

ter

tightening,pullthewireslightlytoconrmthattheydonotmove.

4) Perform 2) and 3) for each indoor unit.

5) Connect power supply cord (A).

6) Fix indoor/outdoor unit connecting wire (B) and power supply cord (A)

with the cable clamps.

7) Close the service panel securely. Make sure that 3-2. PIPE CONNEC

-

TION

is completed.

• After making connections between both power supply cord (A) and

indoor/outdoorunitconnectingwire(B),besuretoxbothcableand

wire with cable clamps.

Indoor/outdoor unit connecting wire

<OUTDOOR UNIT>

35 mm

15 mm

Lead wire

Terminal block

UNIT

UNIT

Terminal

block for

power supply

<INDOOR UNIT>

POWER SUPPLY

~/N 230 V 50 Hz

Service panel

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5 Fig. 6

3. FLARING WORK AND PIPE CONNECTION

3-1. FLARING WORK

Pipe diameter

(mm)

Nut

(mm)

A (mm) Tightening torque

Clutch

type tool

for

R410A

Clutch

type tool

for R22

Wing nut

type tool

for R22

N•m kgf•cm

ø6.35 (1/4”) 17

0 to 0.5 1.0 to 1.5

1.5 to 2.0

13.7 to 17.7 140 to 180

ø9.52 (3/8”) 22 34.3

to 41.2 350 to 420

ø12.7 (1/2”) 26

2.0

to 2.5

49.0 to 56.4 500 to 575

ø15.88 (5/8”) 29 73.5

to 78.4 750 to 800

Tilted Uneven Burred

Good

No good

Burr

Copper pipe

Spare reamer

Pipe cutter

Smooth all

around

Even

length

all around

Inside is shin-

ing

without any

scratches.

Flare nut

Die

Copper

pipe

Clutch type

Flaring tool

Wing nut type

Copper

pipe

1) Cut the copper pipe correctly with pipe cutter. (Fig. 1, 2)

2) Completely remove all burrs from the cut cross section of pipe. (Fig. 3)

• Aim the copper pipe downward while removing burrs to prevent

burrs from dropping in the pipe.

3)Removearenutsattachedtoindoorandoutdoorunits,thenputthem

on pipe having completed burr removal. (Not possible to put them on

afteraringwork.)

4) Flaring work (Fig. 4, 5). Firmly hold copper pipe in the dimension

shown in the table. Select A mm from the table according to the tool

selected.

5)

Check

• ComparethearedworkwithFig.6.

• Ifareisnotedtobedefective,cutoffthearedsectionanddoar

-

ing

work again.

JG79A641H01_en.indd 3 2013/09/06 15:47:06

Loading ...

Loading ...

Loading ...