Loading ...

Loading ...

Loading ...

13

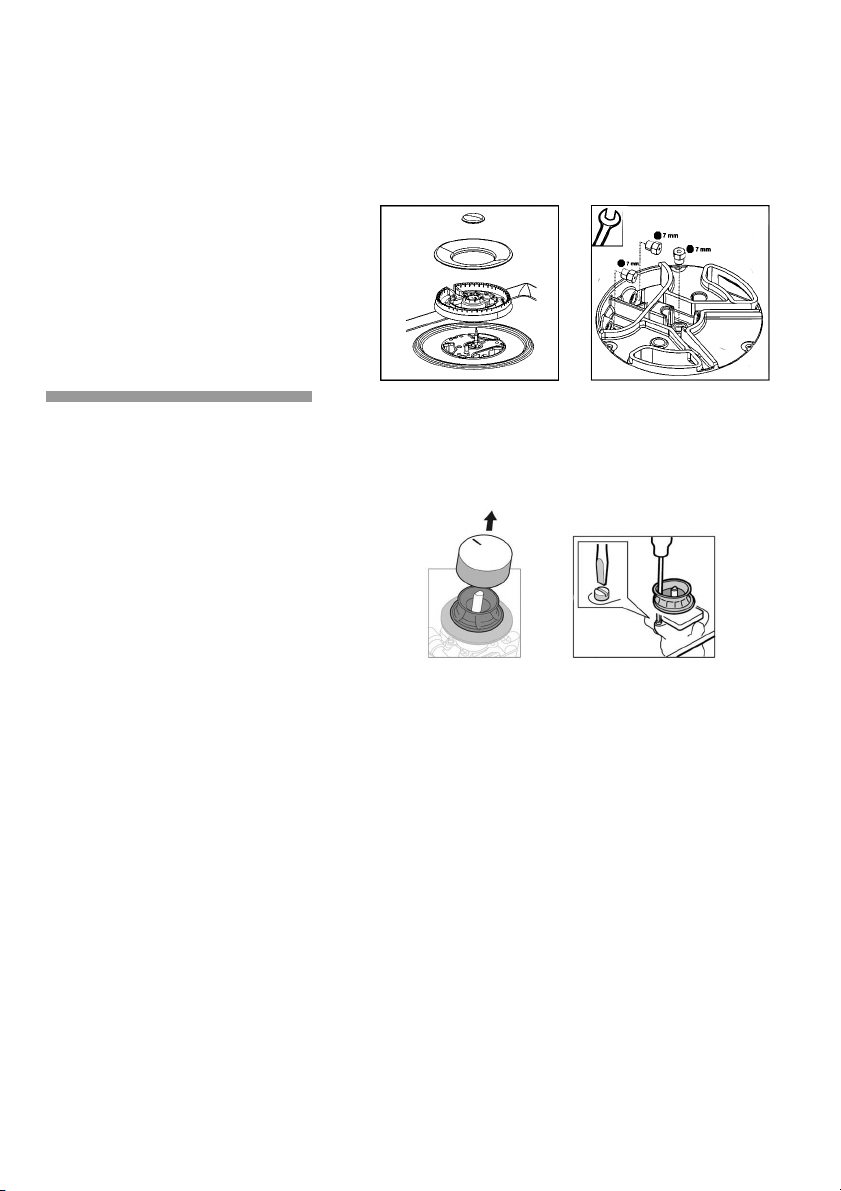

- Change the nozzles using the spanner provided by our

Service Centre (code 340847, for double and triple flame

burners code 340808), taking special care to ensure that

the nozzle does not fall when it is removed from the

burner or when fitted. Fig. 8.

Ensure that it is completely tightened in order to

guarantee the seal.

Adjustment of the

taps

Set the control knobs to minimum.

Remove the control knobs from the taps. Fig. 9.

It has a flexible rubber valve reinforcing ring. Simply press

on this seal with the tip of a screwdriver to allow access

to the tap adjusting screw.

Never remove the valve reinforcing ring.

Adjust the minimum ring setting by turning the by-pass

screw using a flat head screwdriver.

To adjust the minimum flame for N.G. replace the control

knob onto the spindle, light the gas and turn the control

knob to the small flame position. Screw the adjustment

screw anti-clockwise to estabilish a minimum stable

flame position. The flame should remain alight and not

burn back to the injector when the valve is turned

quickcly from ‘Full On’ to the “Minimum flame” position

and back a few times. To adjust the minimum flame

position for ULPG the screw must be fully tightened down

clockwise.

If the by-pass screw cannot be accessed, disassemble

the grease splash tray, which is fixed to the rest of the

hob using a clip and screw mounting system. The

following steps must be taken to remove the grease

splash tray:

- Remove all the burner covers, pan supports and

control knobs.

- Loosen the screws on the burners.

Use the disassembly lever 483196 available from our

Fig. 8

Fig. 9

Loading ...

Loading ...

Loading ...