Loading ...

© Tasman Sinkware

TF 45c August 2013

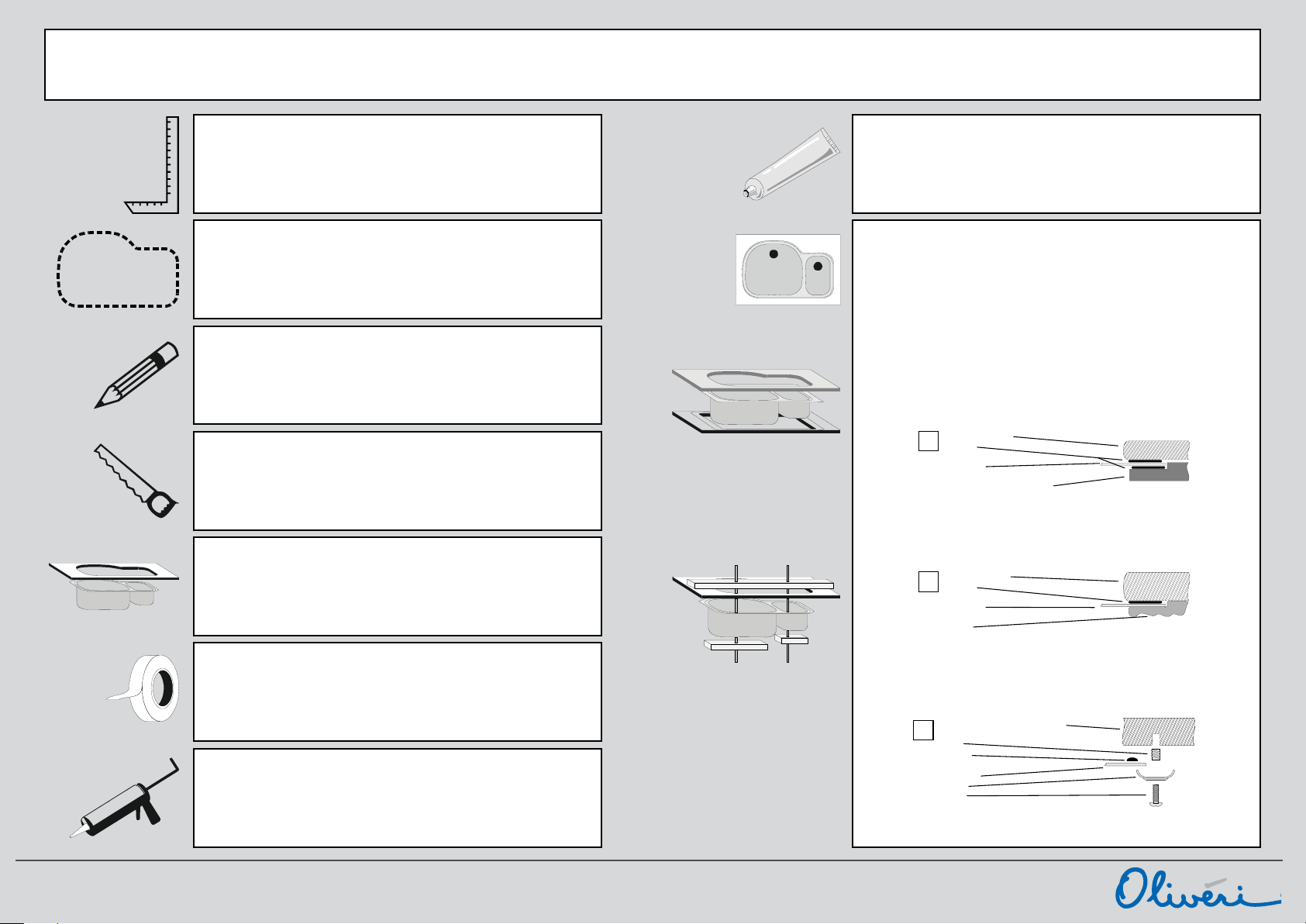

FOLLOW THESE STEPS TO INSTALL THE OLIVERI UNDERMOUNT SINK

IF COUNTER / BENCHTOP IS SUPPLIED WITH CUT-OUT, SKIP STEPS MARKED WITH*

CHECK SPACE

Ensure there is adequate space for tapware (including a splashback

ifspecied).Checkspaceforinstallation(underneath)andoperation

(above). Particular care must be taken when a thick splash back is

used (it may interfere with tapware location and operation). Ensure the

cabinetwillnotfoulthesinkmountingangeorbasins.

ADDITIONAL FASTENING

The sealant alone may appear to bond the sink to the counter/

benchtop. However, when installing your Oliveri undermount sink, it

is important to always use methods A, B or C (below) to locate the

sink securely in the counter/bench top in conjunction with the sealant

manufacturer’s instructions.

FITTING THE SINK

Position and align the sink correctly in the cutout (some threaded rod

and timber bearers will help to clamp the sink in place) and either

‘A’ Sandwich Method: RECOMMENDED FOR BOTH THIN AND

THICKCOUNTER/BENCHTOP.Firmlyxasupportboardinto/over

thecabinetandcutthesinkholesothatthesinkangewillsitabove

theedgeoftheboard.Slightlyrouttheedgesothatthesinkangewill

situshwiththetopsurface.Testfort.Installsinkandsealbetween

angeandsupportboard.Applysealanttotheundersideedgeofthe

cutout on counter/benchtop material and position it over the support

board to sandwich the sink in place. Fasten the counter/benchtop

securely.

‘B‘ Bond: For minimum 1” / 25mm thick material. Bond it to the

underside of the counter/benchtop with a structural high strength epoxy

compound. NOT RECOMMENDED TO BE USED WHEN FITTING

SINK TO THINNER COUNTER/BENCHTOPS.

‘C‘ Bolt: For minimum 1” / 25mm thick material. Bolt it to the counter /

benchtop using “molly” assemblies. Care must be taken during drilling

and tightening to avoid cracking. NOT RECOMMENDED TO BE USED

WHEN FITTING SINK TO THINNER COUNTER/BENCHTOPS.

Ifyouhaveanydoubts,conrmthecorrectmountingmethodfor

your material by consulting the counter/benchtop supplier.

TEMPLATE *

Cut out templates for your Oliveri sink are available online at

oliverisinks.com.Usetheproductmodelnumbertondthetemplate.

Some sink templates apply to both left-hand and right-hand

modelssinks. Ensure template is correct way around for your model.

MARK CUT OUT *

Carefully mark out the template (or follow drawing instructions) making

allowance for any additional polishing back that is required after cutting.

NOTE: THE TEMPLATE IS THE EXACT FINISHED CUT-OUT SIZE

REQUIRED.

CUT & FINISH HOLE *

Drill pilot holes to accept an appropriate cutting tool for the counter/

benchtop material (wear suitable personal protection equipment). Cut

insidethemark,allowingsufcientroomforanypolishingback.

Note: Accuracy is essential to ensure the bowl / basin and

accessoriestcorrectly.

TRIAL FIT THE SINK

Carefully position the sink against counter/benchtop to make sure it

tsthecut-outcorrectly.Ifthetisnotcorrect,removethesinkand

proceedwithremedialwork.Performanothertrialtaftercorrections

have been made.

MASKING

To prevent sealant overrun, it is recommended that both the inside

edge of the basin and the edge of the cut-out is covered with a suitable

masking tape.

APPLY SEALANT

Apply suitable sealant recommended for both the counter/benchtop

material being used and for stainless steel. Neutral-cure sealant will

not damage stainless steel. It may be easier to apply sealant after

preparing your clamping equipment. Do not allow the sealant to dry

before the sink is clamped to the counter/benchtop.

Above shows sandwich method

where sink is clamped between a

lower support board (with routed

edge) and the upper counter /

benchtop using method A.

Above shows how threaded rod

and timber bearers may be used

to clamp the sink in place while

fastening to the counter / benchtop

using methods B and C.

Do not overtighten as this may

damage the sink.

Counter / benchtop

Sealant

Sink flange

Support board with routed edge

(such as timber)

A

Counter / benchtop

Sealant

Sink flange

Epoxy

B

1” Counter / benchtop with hole drilled

Molly

Sealant

Sink flange

Saddle

Screw

C