Loading ...

Loading ...

Loading ...

10

Installation instructions

Leak-testing and flame-testing the cooktop

1

After connecting the gas supply, check the piping and connections for leaks using a soap and

water solution. The presence of bubbles indicates a leak. Tighten or replace connections as

appropriate.

Important!

Do not use any naked flame to check for leaks.

2

The operation of the appliance MUST be tested before leaving.

3

Adjust the test point pressure or supply pressure to the value which is appropriate for the gas

type.

4

Turn on the appliance gas controls and light each burner. Check for a well defined blue flame

without any yellow tipping. If any abnormality is evident, check that the burner cap is located

properly and the injector nipple is aligned correctly.

5

Check the minimum burner setting by quickly rotating the gas control knob from the maximum

to the minimum position. The flame must not go out. If adjustment is required, see ‘Adjusting the

minimum burner setting’ section following.

6

If satisfactory performance cannot be obtained, the installer shall check the installation and

notify the local gas supply authority about a gas supply problem, or if it is an appliance problem,

our Customer Service Centre should be called to obtain the nearest authorised Service Agent.

7

Where the appliance data plate cannot be easily read with the appliance installed, the duplicate

data plate must be attached to an adjacent surface and the duplicate Natural gas or LPG

conversion label should also be included where a Natural gas or LPG conversion has been

completed.

Installation with a flexible hose assembly

If this appliance has to be installed with a hose assembly, the installer must refer to the network

operator or gas supplier for confirmation of the gas type, if in doubt.

When used with a flexible hose, the connector on the wall should be between 800 mm to 850

mm above the floor and in the region outside the width of the appliance to a distance of 250

mm. The supply connection point shall be accessible with the appliance installed.

Flexible hose assemblies should be AS/NZS 1869 Class B or Class D certified. The thread

connection shall be Rp 1/2” (ISO 7-1) male.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261

requirements.

Important!

After connection, the installer must check that the hose is not kinked, subjected to abrasion or

permanently deformed. The installer must check also that the hose is not near (or in contact) with

any hot surfaces eg. base of metal hotplate, underbench oven etc.

The installer shall ensure the hose assembly is restrained from accidental contact with the flue

outlet of an underbench oven.

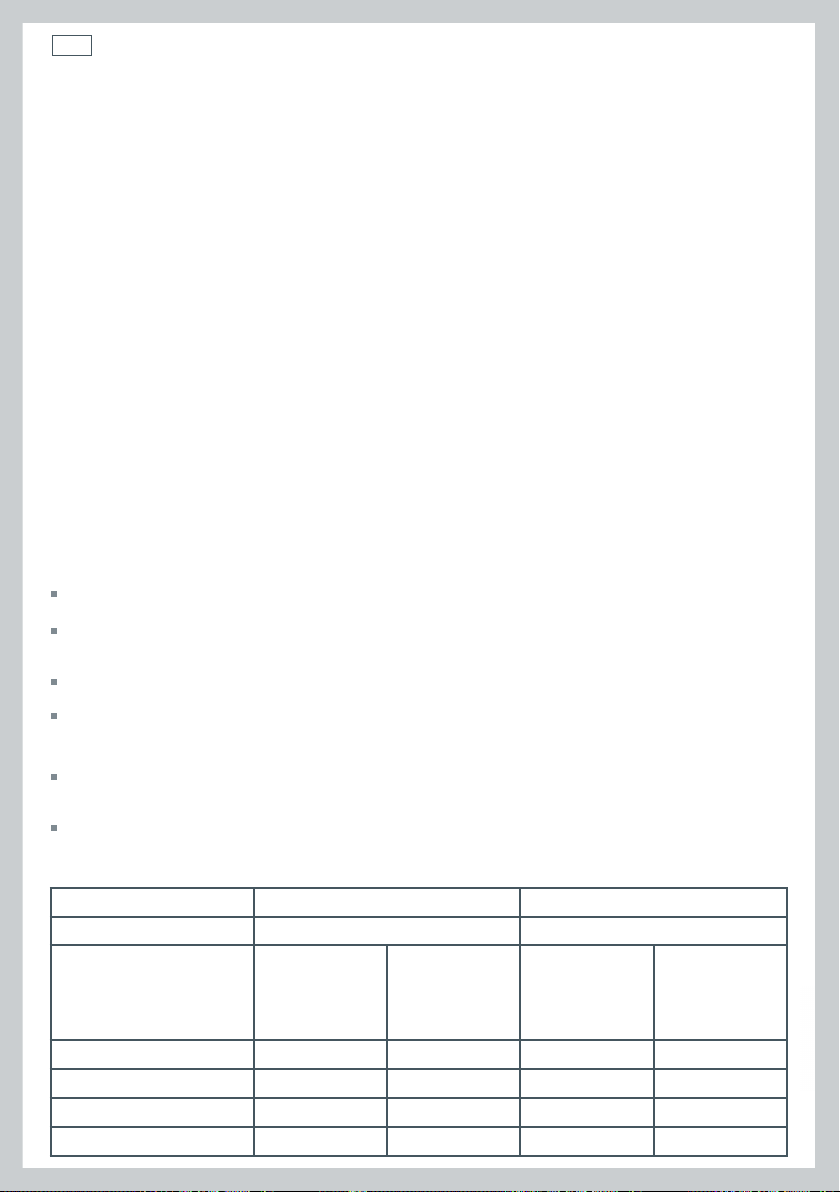

Table for the choice of injectors

Natural Gas LPG

Test point Pressure [kPa] 1.0 2.75

BURNER

Injector

Ori ce Dia.

[mm]

Gas

Consumption

[MJ/h]

Injector

Ori ce Dia.

[mm]

Gas

Consumption

[MJ/h]

Auxiliary 0.85 3.60 0.53 3.60

Semi-rapid 1.12 6.30 0.70 6.30

Rapid 1.45 10.30 0.91 10.80

Triple-ring wok 1.60 12.70 0.95 11.90

Loading ...

Loading ...

Loading ...