Loading ...

Loading ...

2. Convert Burners for use with LP/Propane Gas:

THiS COOKTOP iS NOT REMOVABLE. Do

not attempt to remove the cooktop.

Use caution when replacing each burner cap so

the electrode is not damaged.

Save the natural gas orifices removed from the appliance for possible

future conversion back to natural gas. For all burner locations:

a. Remove Burner Grates & Burner Caps & Burner Heads

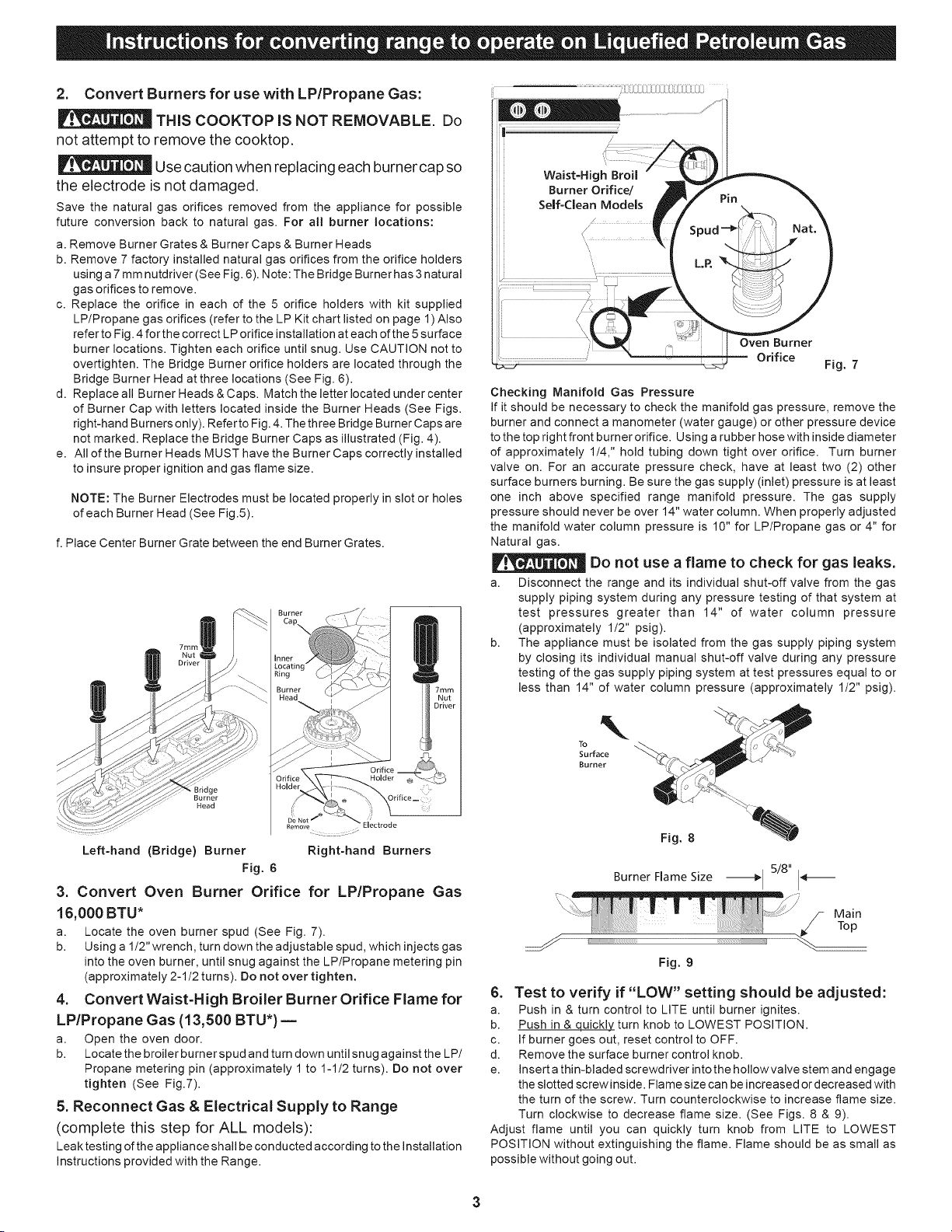

b. Remove 7 factory instaled natural gas orifices from the orifice holders

using a 7mm nutdriver (See Fig. 6). Note: The Bridge Burner has 3natural

gas orifices to remove.

c. Replace the orifice in each of the 5 orifice holders with kit suppled

LP/Propane gas orifices (refer to the LP Kit chart lsted on page 1) Also

refer to Fig. 4 for the correct LP orifice instalation at each of the 5 surface

burner locations. Tighten each orifice untl snug. Use CAUTION not to

overtighten. The Bridge Burner orifice holders are located through the

Bridge Burner Head at three locations (See Fig. 6).

d. Replace al Burner Heads &Caps. Match the letter located under center

of Burner Cap with letters located inside the Burner Heads (See Figs.

right-hand Burners only). Rder to Fig. 4. The three Bridge Burner Caps are

not marked. Replace the Bridge Burner Caps as llustrated (Fig. 4).

e. AI of the Burner Heads MUST have the Burner Caps correctly instaled

to insure proper ignition and gas flame size.

NOTE: The Burner Electrodes must be located properly in slot or holes

of each Burner Head (See Fig.5).

f. Place Center Burner Grate between the end Burner Grates.

7mm

Nut

Driver

Head

Remove

Left-hand (Bridge) Burner Right-hand Burners

Fig, 6

3. Convert Oven Burner Orifice for LP/Propane Gas

16,000 BTU*

a. Locate the oven burner spud (See Fig. 7).

b. Using a 1/2" wrench, turn down the adjustable spud, which injects gas

into the oven burner, until snug against the LP/Propane metering pin

(approximately 2-1/2 turns). Do not over tighten.

4. Convert Waist-High Broiler Burner Orifice Flame for

LP/Propane Gas (13,500 BTU*) m

a. Open the oven door.

b. Locate the broiler burner spud and turn down until snug against the LP/

Propane metering pin (approximately 1 to 1-1/2 turns). Do not over

tighten (See Fig]).

5. Reconnect Gas & Electrical Supply to Range

(complete this step for ALL models):

Leak testing of the appliance shall be conducted according to the Installation

Instructions provided with the Range.

Waist-High Broil

Burner Orifice/

Self-Clean Models

Oven Burner

Orifice

Fig. 7

Checking Manifold Gas Pressure

If it should be necessary to check the manifold gas pressure, remove the

burner and connect a manometer (water gauge) or other pressure device

to the top right front burner orifice. Using a rubber hose with inside diameter

of approximately 1/4," hold tubing down tight over orifice. Turn burner

valve on. For an accurate pressure check, have at least two (2) other

surface burners burning. Be sure the gas supply (inlet) pressure is at least

one inch above specified range manifold pressure. The gas supply

pressure should never be over 14" water column. When properly adjusted

the manifold water column pressure is 10" for LP/Propane gas or 4" for

Natural gas.

Do not use a flame to check for gas leaks.

a. Disconnect the range and its individual shut-off valve from the gas

supply piping system during any pressure testing of that system at

test pressures greater than 14" of water column pressure

(approximately 1/2" psig).

b. The appliance must be isolated from the gas supply piping system

by closing its individual manual shut-off valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than 14" of water column pressure (approximately 1/2" psig).

%

To

Surface

Burner

Burner Flame Size _1 518" 14___

MainTop

Fig. 9

6. Test to verify if "LOW" setting should be adjusted:

a. Push in & turn control to LITE until burner ignites.

b. Push in & quickly turn knob to LOWEST POSITION.

c. If burner goes out, reset control to OFF.

d. Remove the surface burner control knob.

e. Insert a thin-bladed screwdriver into the hollowvalve stem and engage

the slotted screw inside. Flame size can be increased or decreased with

the turn of the screw. Turn counterclockwise to increase flame size.

Turn clockwise to decrease flame size. (See Figs. 8 & 9).

Adjust flame until you can quickly turn knob from LITE to LOWEST

POSITION without extinguishing the flame. Flame should be as small as

possible without going out.

Loading ...