Loading ...

Loading ...

Loading ...

24

Dryer

Safety

Operation

Requirements

Parts and

Features

Installation

Instructions

Dryer Use

Appendix

Dryer Care

Troubleshooting

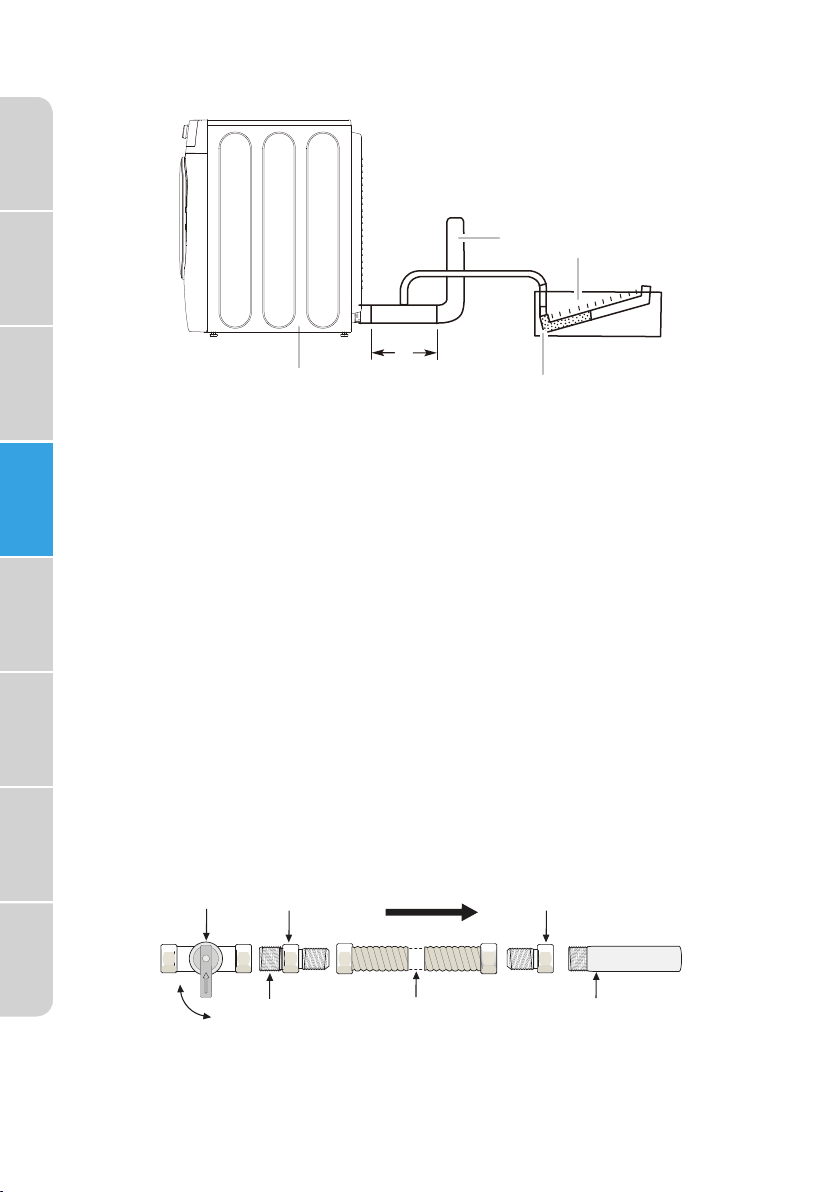

MEASURING AND VERIFYING ACTUAL SYSTEM BACK PRESSURE

a

b

c

d

e

a Dryer - empty and running on Air

Fluff cycle

b 10" (254 mm) min. of straight

pipe - measure back pressure

from the center

c To vent system

d Location on back

pressure measurement

e Inclined manometer

CONNECT THE GAS LINE (FOR GAS MODELS)

Review the “Gas Requirements” section on page 15. Remove the pipe

thread protective cap.

Apply a pipe joint compound or about 1 " wraps of teflon tape over all

threaded connections.

•

The pipe joint compound must be resistant to the actions of any

liquefied petroleum gas.

Connect the gas supply to your dryer. An additional fitting is required

to connect the " (1.9 cm) female thread end of a flexible connector to

the " (1 cm) male threaded end on the dryer. Use only new AGA or CSA

certified gas supply line with SS flexible connectors. within 6 ft (1.8 m) of

the dryer

Securely tighten the gas line fitting over the threads.

Turn on the gas supply.

Manual

Shutoff

Valve

Flare

Union

Flare

Union

Open

Nipple Flexible

Connector

Inlet Pipe on

Back of Dryer

GAS FLOW

All connections must be wrench-tightened

Loading ...

Loading ...

Loading ...