Loading ...

Loading ...

Loading ...

11

Adjusting the CO

2

Regulator

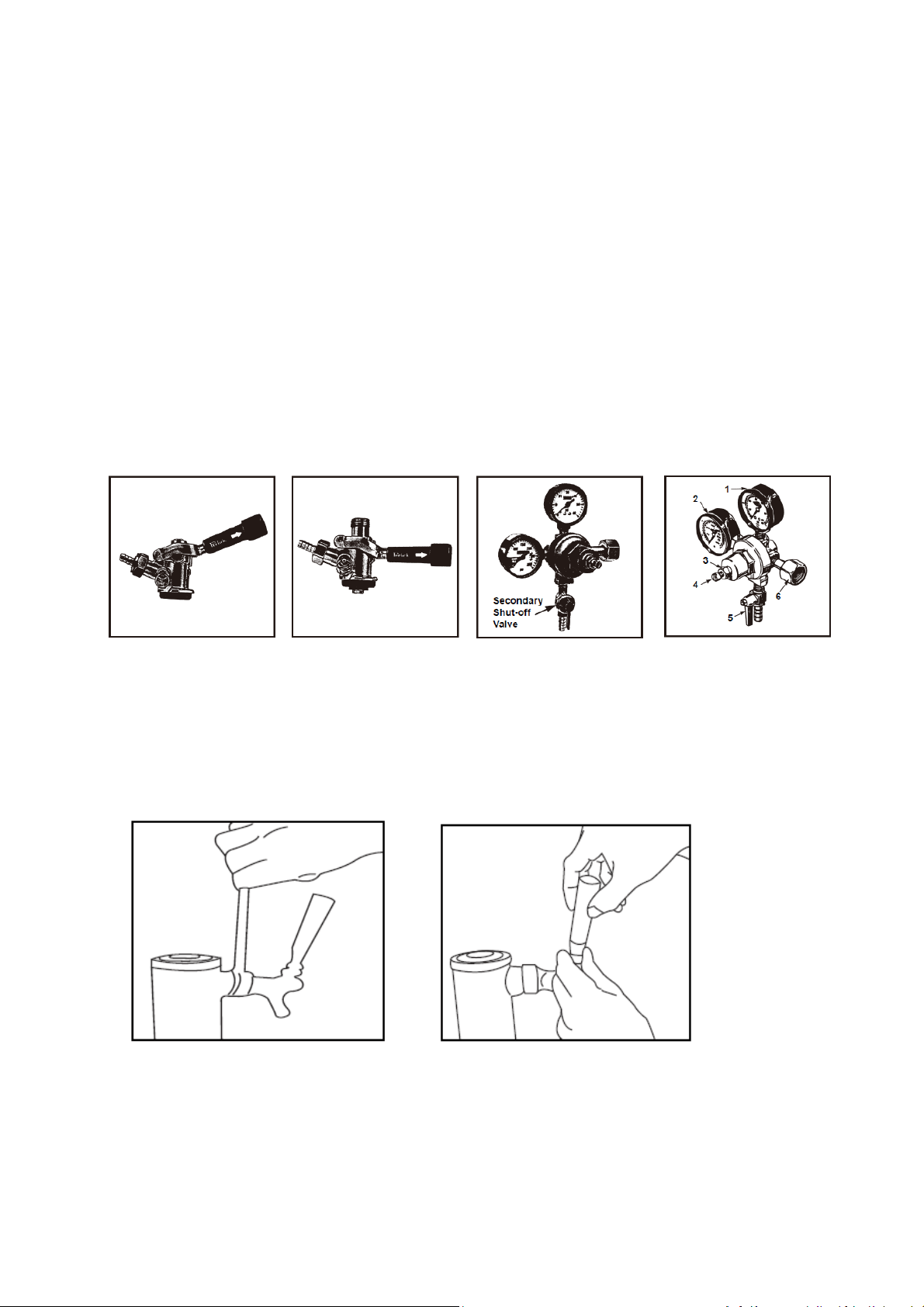

There are two pressure gauges on the CO

2

regulator. The upper gauge #1 monitors

"LOW" (internal keg) pressure and must be adjusted to the correct operating pressure

of 10~12psi/lbs. The lower gauge #2 monitors "HIGH" (CO

2

cylinder) pressure and is

not adjustable. The high pressure gauge also acts as a fuel gauge to let you know

when the C0

2

cylinder needs re-filling.

IMPORTANT: The internal operating pressure of the beer keg should be adjusted

and maintained between 10~ 12psi/lbs. To adjust the "LOW" pressure gauge:

• Using an adjustable wrench, release the adjustment lock nut # 3 (Figure 12).

• Using a flat screwdriver, turn the regulator adjustment screw # 4 (Figure 12).

Clockwise rotation of the adjustment screw will increase low pressure. Counter-

clockwise rotation of the adjustment screw will decrease low pressure

• When the required operating pressure is attained, tighten the adjustment lock

nut # 3.

Plastic Faucet Lever

Attach the black plastic lever (pull handle) to the top of the faucet by tightening it by

hand clockwise until the end, holding in the silver nut underneath so it does not turn. If

there is still a small drip from the faucet, you may have tightened the plastic lever too

much and may need to unscrew silver nut counter-clockwise (as shown) one turn.

Guard Rail

1. Place guard rail on top of cabinet.

2. Fit the legs of the guard rail into the prepared holes in the cabinet top.

3. Secure the guard rail to the cabinet with the eight small Phillips-head screws.

Figure 9 Figure 10 Figure 11 Figure 12

Loading ...

Loading ...

Loading ...