Loading ...

Loading ...

Loading ...

11

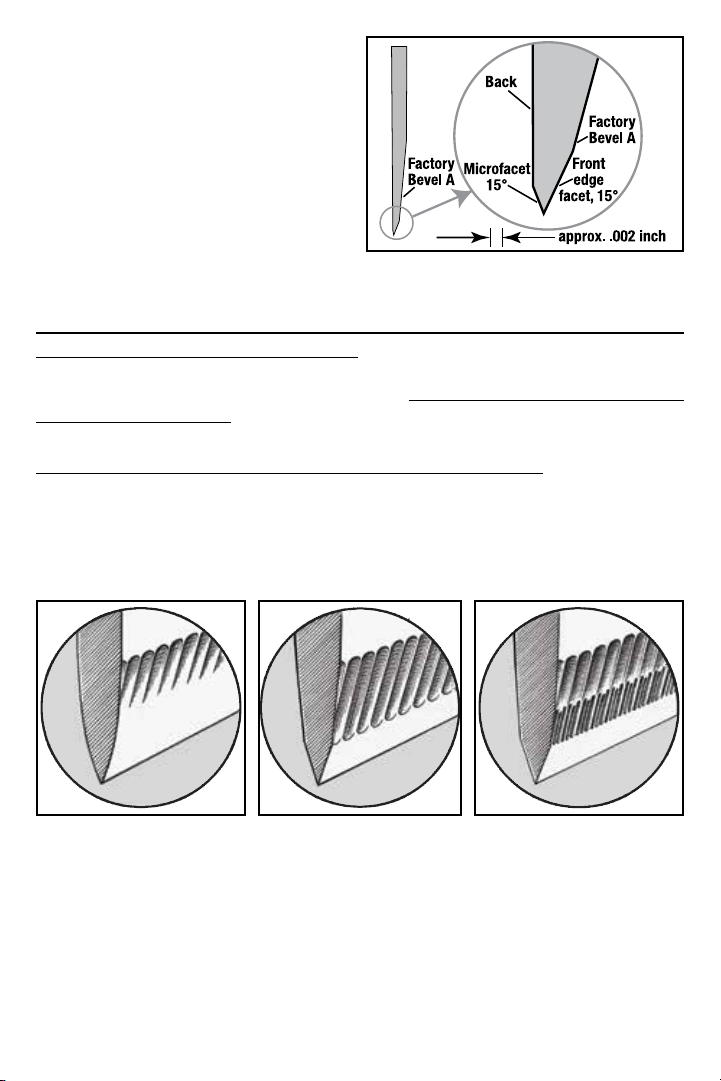

front of the edge of the sashimi blade as shown in

Figures 10c and 10d in order to establish the ge-

ometry of the cutting edge. An even smaller cutting

micro-facet (barely visible to the unaided eye) is

customarily created on the back face of the blade to

enhance the sharpness of the finished edge. Figure

10d shows a greatly enlarged cross-section view of

a typical factory edge on the traditional single-bevel

Japanese knife. The large factory bevel A serves

to deflect the food slice away from the blade as it

is cut. When sharpening the traditional Japanese

blades, always follow the instructions carefully. Also

remember these knives will be extremely sharp.

THE EDGESELECT

®

FEATURE –

OPTIMIZING THE KNIFE EDGE FOR EACH USE

The gourmet chef will appreciate the unique ability of the Model 15 to tailor the knife edge to

optimize performance for each individual cutting task. These procedures are not suggested for

your traditional Asian knives.

GOURMET FOOD PREPARATION:

(EUROPEAN, AMERICAN, AND CONTEMPORARY ASIAN KNIVES)

Where the finest and smoothest cuts are preferred in order to prepare smooth unmarked

sections of fruits or vegetables, sharpen in Stages 1 & 2 as described above and make extra

pulls thru Stage 3. Three or more pairs of fast pulls with each pull alternating in the left and

right slots of Stage 3 will refine the third facet and create remarkably smooth and sharp edges,

(Figure 11a) ideal for the gourmet chef.

Figure 10d. Cross-section of a typical factory traditional

Asian knife edge, magnified 50x (right-handed).

Figure 11a. A larger polished facet

adjacent to edge is ideal for

gourmet preparations.

Figure 11b. Retention of larger

microflutes adjacent to edge helps

when cutting fiberous foods.

Figure 11c. For fish and poultry

retention of finer microflutes

adjacent to edge can be helpful.

Loading ...

Loading ...

Loading ...