Loading ...

Loading ...

Loading ...

5

Adapting the hob to different types of gas

To adapt the Hob for use with different types of gas, carry out the following instructions:

— remove the grids and burners

— insert the hexagonal spanner (supplied) into the burner support (Fig. 5)

— unscrew the injector and replace it with one suitable for the gas to be used (see

Table page 6).

When you have carried out the new gas regulation, replace the old gas rating plate

on your appliance with one (supplied with hob) suitable for the type of gas for which

it has been regulated.

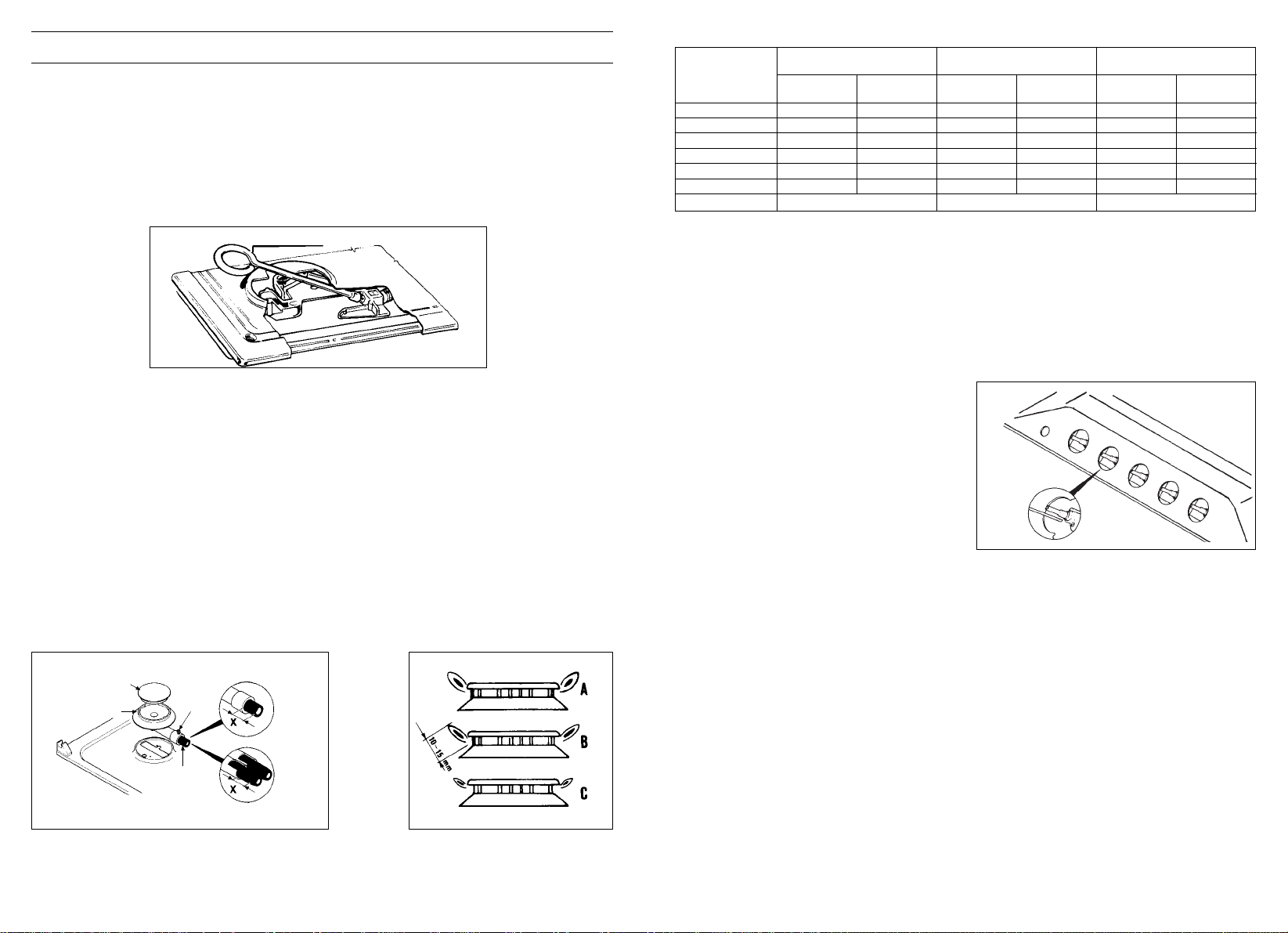

REGULATING THE BURNERS

Flame Combustion

For maximum efficiency from the burners, the correct combustion of the flame is ne-

cessary. A good flame must be well aligned and without yellow tips (Fig. 7/B). If there

is insufficient air, the flame will be uneven with yellow tips (Fig. 7/A). If there is too much

air, the flame will be very short and bright (Fig. 7/C). In these cases the combustion

must be adjusted by re-fitting the carburation tube to the Venturi (where there is insuffi-

cient air) or removing the carburation tube (in the case of too much air). To position

the carburation tube, the fixing screws must be loosened, and retightened when the

satisfactory combustion is obtained.

Fig. 6 Fig. 7

BURNER CAP

BURNER

AIR REGULATION

SCREW

FIXING

SCREW

SMALL

MEDIUM

LARGE

DOUBLE RING

MAXI

FISH

For dimensions «X» see attached table

Hexagonal spanner

Fig. 5

Regulating the minimum flame

After lighting the burners, turn the control knob to the minimum setting and then remo-

ve the knob (this can easily be removed by apply a gentle pressure).

Using a small «Terminal» type screwdriver the regulating screw can be adjusted as in

Fig. 8. Turning the screw clockwise reduces the gas flow, whilst turning it anticlockwise

increases the flow – Use this adjustment to obtain a flame of approximately 3 to 4 mm

in length and then replace the control knob.

If GPL (cylinder) gas is being used, turn the screw clockwise right to the end of the

travel of the by-pass.

Screws

regulating

Gas tap calibrating screws

(flat head slot type)

6

Fig. 8

Maxi

Fish

Double ring

Rapid

Semi rapid

Small

Total NHGC

2x110 11

2x110 11

2x110 11

141 10

110 5,7

92 3,8

40,5

2x65 11

2x65 11

2x65 11

81 8,7

65 5,5

52 3,5

37,4

13 mm 13 mm

15 mm 15 mm

13 mm 15 mm

4 mm 5 mm

2 mm 7 mm

6 mm 6 mm

NG

air regul.

MJ/HInjector size

LPG gas

Reg. 2,75 kPa

Natural gas

Reg. 1,0 kPa

MJ/HInjector size

Burner

LPG

air. regul.

Quota «X» depending

on type of gas

Table of gas consumption

PRESSURE ADJUSTMENT

First turn the gas off to the appliance. Remove the sealing screw from the regulators

test point at the rear of the appliance and fit the hose of the Manometer to it.

Turn the gas on and light the Wok Burner and one Medium Burner at maximum set-

ting. Check the pressure and adjust at the regulator if necessary to the settings in the

table below or on the Data plate.

For Propane Gas adjust at the regulator on the cylinder - Turn regulator adjusting

screw clockwise increases pressure whilst anti-clockwise decreases pressure. Refit

the test point sealing screw when finished.

INSTRUCTIONS FOR USE

Using the gas Burner

To ignite the burners, place a lighted taper close to the burner, press in and turn the

control knob anti-clockwise.

If the burners have not been used for a couple of days, wait for a few seconds before

lighting the burner, this will allow any air present in the pipes to escape.

For appliances equipped with electronic ignition, simply press down and turn the con-

trol knob to the position marked with a star

★

.

Loading ...

Loading ...

Loading ...