Loading ...

Loading ...

Loading ...

air

regul.

4mm

13 mm

2mm

6mm

15 mm

15 mm

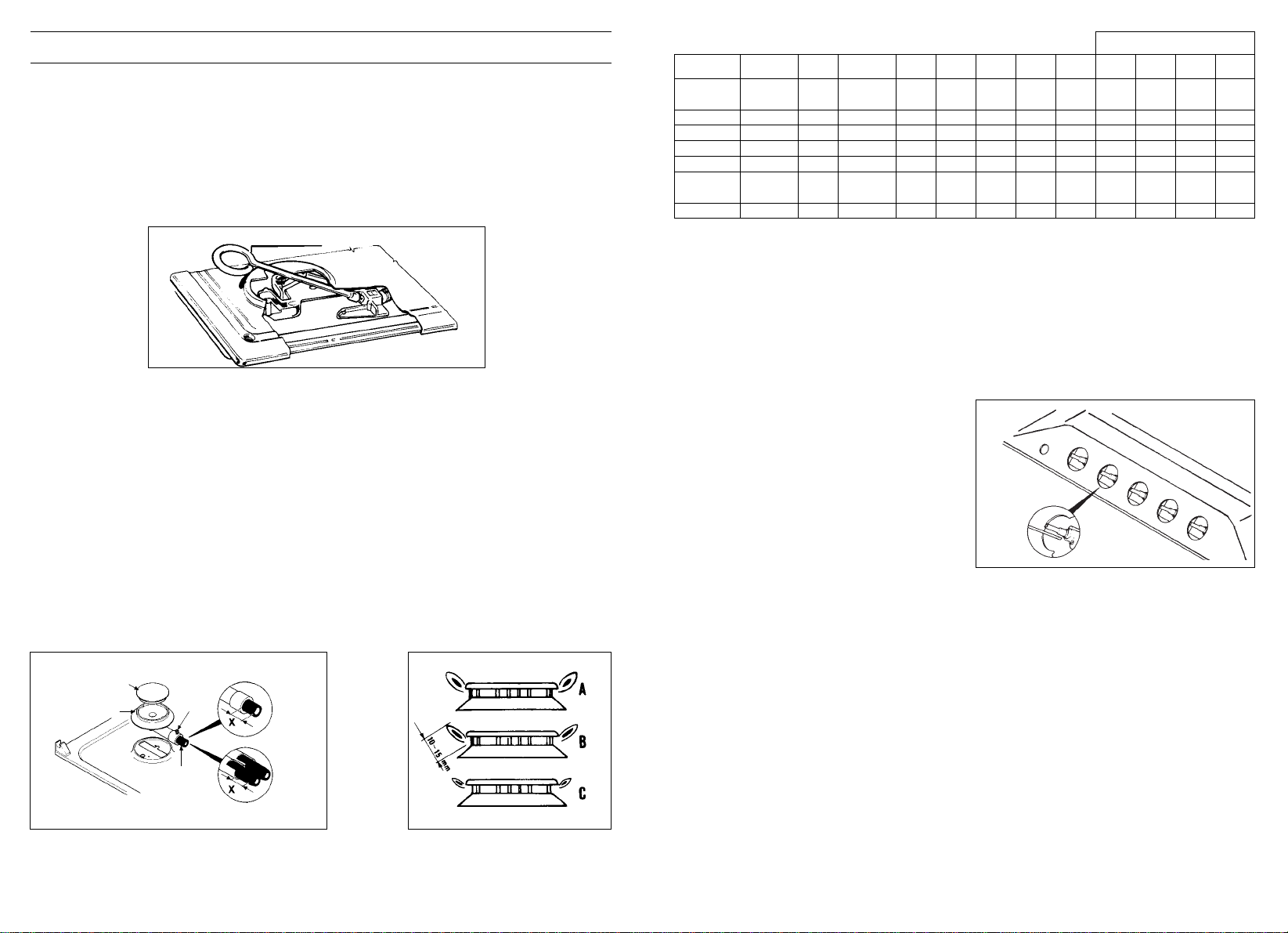

Regulating the minimum flame

After lighting the burners, turn the control knob to the minimum setting and then remo-

ve the knob (this can easily be removed by apply a gentle pressure).

Using a small «Terminal» type screwdriver the regulating screw can be adjusted as in

Fig. 8. Turning the screw clockwise reduces the gas flow, whilst turning it anticlockwise

increases the flow – Use this adjustment to obtain a flame of approximately 3 to 4 mm

in length and then replace the control knob.

If GPL (cylinder) gas is being used, turn the screw clockwise right to the end of the

travel of the by-pass.

Screws

regulating

Gas tap calibrating screws

(flat head slot type)

INSTRUCTIONS FOR USE

Using the gas Burner

To ignite the burners, place a lighted taper close to the burner, press in and turn the

control knob anti-clockwise.

If the burners have not been used for a couple of days, wait for a few seconds before

lighting the burner, this will allow any air present in the pipes to escape.

For appliances equipped with electronic ignition, simply press down and turn the con-

trol knob to the position marked with a star

★

.

After the burner ignites, turn the knob to the control setting required.

The ignition is by repetitive spark generation; in case the burner does not light at once,

keep the knob in the ignition position for a maximum of 5 seconds.

If the burner does not ignite in this time, switch off the control knob and repeat the opera-

tion again.

As a safety device, some models automatically cut off the gas supply if the flame is

ac-

cidently extinguished. In this case, push and rotate the control knob until the

★

position

and keep it held

down for approx 5-6 seconds.

The burner will then remain lit.

39

Fig. 8

Working

burner

large

double ring

medium

small

fish

maxi

Ø injector

1/100 mm

120

2x94

93

80

2x94

2x94

Ø injector

1/100 mm

80

2x65

61

54

2x65

2x65

Qn

kW

2,65

3,3

1,5

1,1

3,3

3,3

l/h

G20

252

314

143

105

314

314

g/h

G30

193

238

109

80

238

238

Qn

kW

2,5

3,1

1,45

1,05

3,1

3,1

l/h

G25

277

343

161

116

343

343

Qmin.

kW

0,570

0,900

0,380

0,250

0,900 G30

1 G20/G25

0,900

air

regul.

4mm

13 mm

2mm

6mm

15 mm

15 mm

air

regul.

2mm

0mm

5mm

4mm

0mm

0mm

G20 G30 G25 G31

G30G20/G25 G20/G30 G25

Quota «X» depending

on type of gas

Table of gas consumption 1W = 0,860 kcal/h

air

regul.

5mm

15 mm

7mm

6mm

15 mm

15 mm

38

Adapting the hob to different types of gas

To adapt the Hob for use with different types of gas, carry out the following instructions:

— remove the grids and burners

— insert the hexagonal spanner (supplied) into the burner support (Fig. 5)

— unscrew the injector and replace it with one suitable for the gas to be used (see

Table page 28).

When you have carried out the new gas regulation, replace the old gas rating plate

on your appliance with one (supplied with hob) suitable for the type of gas for which

it has been regulated.

REGULATING THE BURNERS

Flame Combustion

For maximum efficiency from the burners, the correct combustion of the flame is ne-

cessary. A good flame must be well aligned and without yellow tips (Fig. 7/B). If there

is insufficient air, the flame will be uneven with yellow tips (Fig. 7/A). If there is too much

air, the flame will be very short and bright (Fig. 7/C). In these cases the combustion

must be adjusted by re-fitting the carburation tube to the Venturi (where there is insuffi-

cient air) or removing the carburation tube (in the case of too much air). To position

the carburation tube, the fixing screws must be loosened, and retightened when the

satisfactory combustion is obtained.

Fig. 6 Fig. 7

BURNER CAP

BURNER

AIR REGULATION

SCREW

FIXING

SCREW

SMALL

MEDIUM

LARGE

DOUBLE RING

MAXI

FISH

For dimensions «X» see attached table

Hexagonal spanner

Fig. 5

Loading ...

Loading ...

Loading ...